Precision Shear-Bend Solution / Efficient Shear-Bend Solution

- Price

- US $4800-5000

- Model

- Solution

- MOQ

- 1 piece

Item specifics

- Multi-Process Integration

- Combines cutting, bending, punching, and welding i

- Space & Cost Saving

- Reduces the need for multiple machines, lowering e

- High Efficiency & Precision

- Automated workflow ensures consistent quality and

Review

Description

All-in-One Metal Fabrication Solutions

About Us

Our Company

Nanjing RONGWIN Machinery Technology Co., Ltd., with 15+ years of expertise, is a global leader in smart press brakes and sheet metal fabrication, Known for reliability and 85%+ customer satisfaction,we deliver customized machinery, spare parts, and lifetime support. In 2022, we launched MetalworkMaster, integrating Industry 4.0 intelligence for tailored manufacturing systems. Our "Win-Win philosophy drives innovation, including lo T-connected press brakes, enhancing efficiency, precision, and sustainability. Serving 150+ countries across six continents, RONGWIN empowers clients with energy-saving, high-performance solutions-forging the future of smart manufacturing.

Why Us?

Full-lifecyele servicecommitment

24/7 Multilingual Support

82% Repeat Purchase Rate

15 years press brake manufacturing experience

All-in-One Sheet Metal Solution

Sheet Metal Solution Equipment Combination

Sheet Metal Solution A:Laser + bending efficient combination

Key Performance

Cutting accuracy:±0.1mm (stainless steel)

Bending speed:0.5 seconds/knife

Mold change time:<3 minutes

Linked operation:90 seconds/piece (standard box)

Fiber Laser Cutting Machine

Electric CNC Press Brake

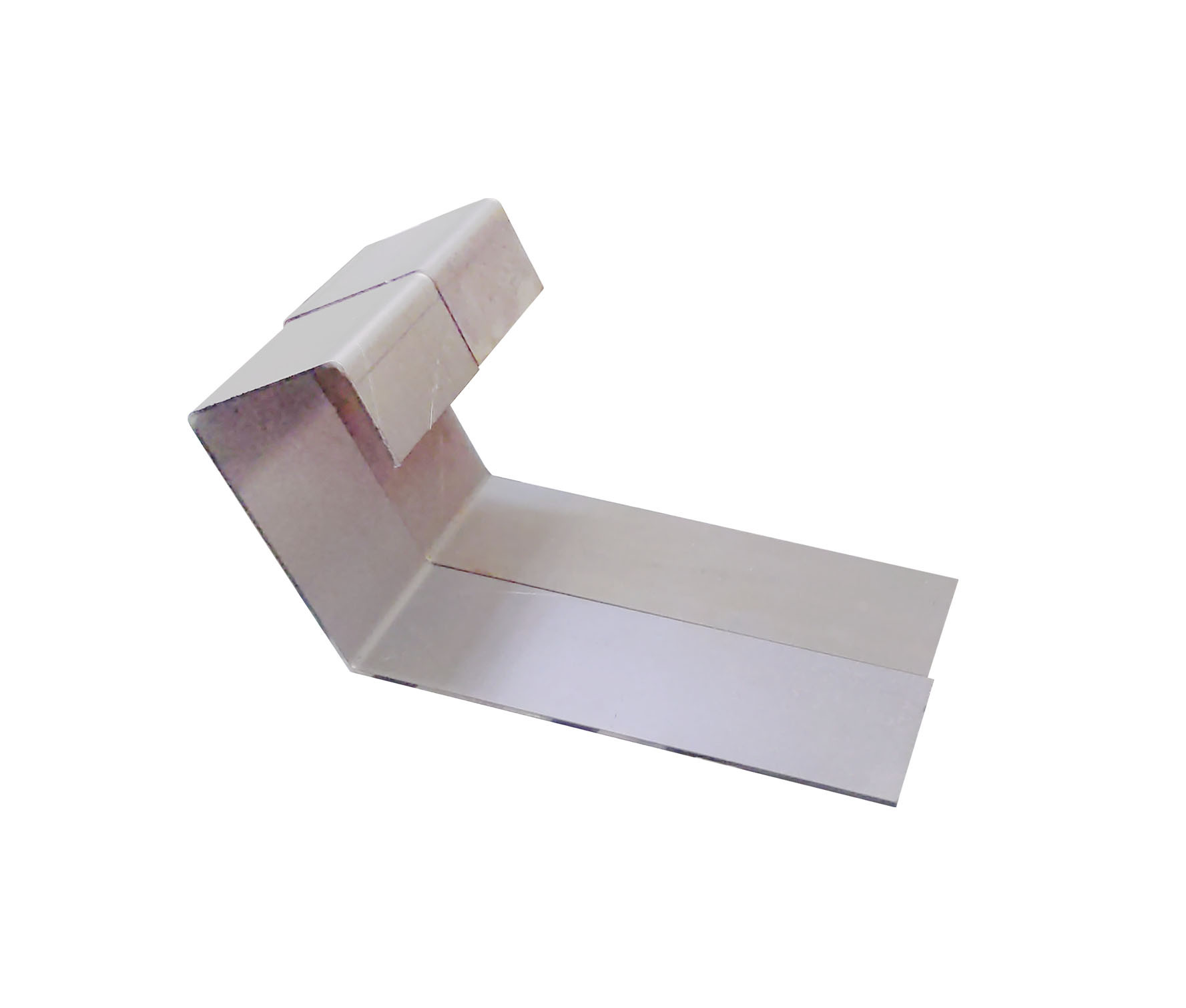

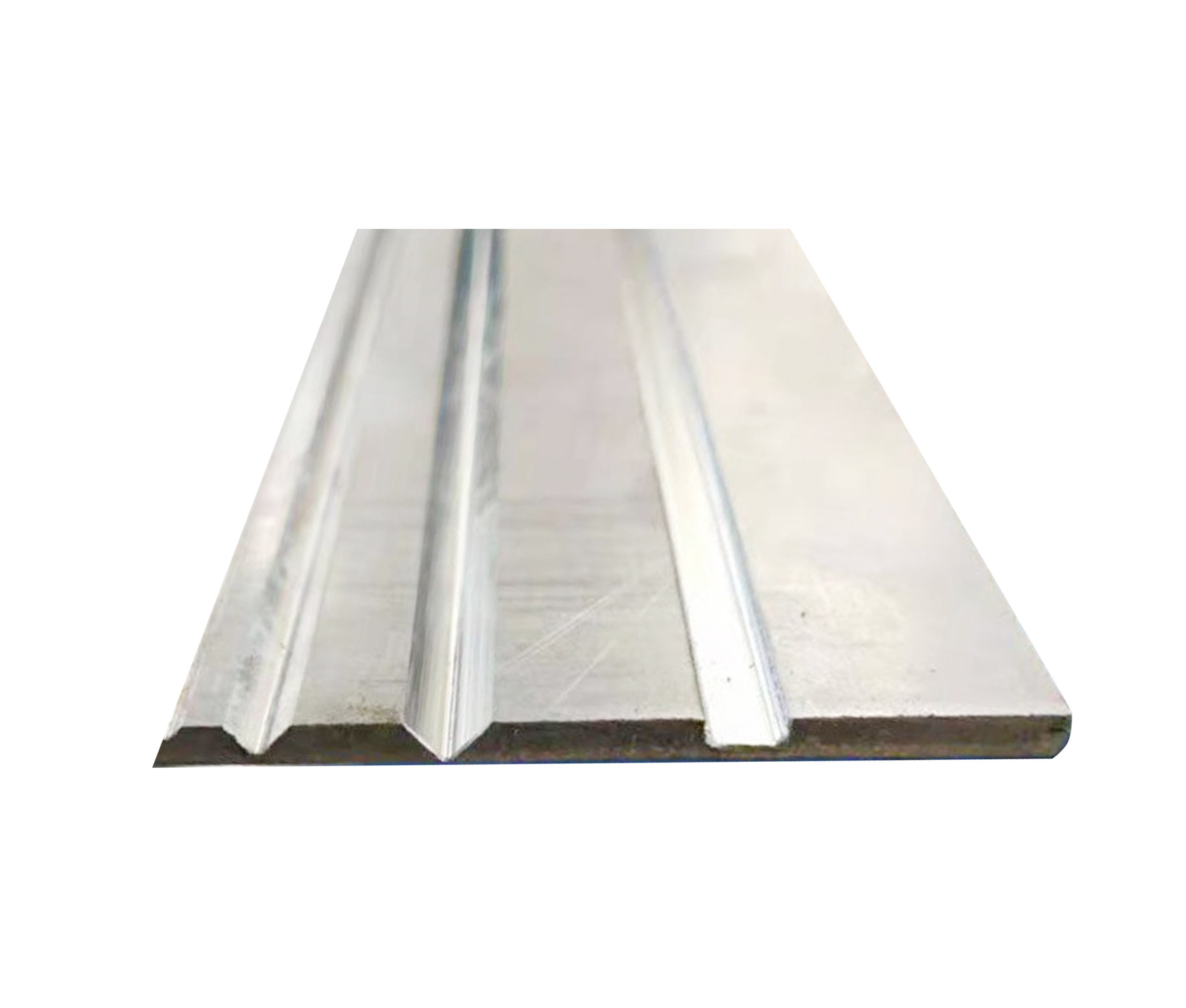

Sheet Metal Solution B: Laser + slotting + bending three machines in one

Key Performance

Groove surface finish:Ra 0.8 (no burrs)

Slotting accuracy:±0.02mm (depth control)

Bending compensation:AI predicted springback (±0.03°)

Automatic flow:Eliminate deformation during secondary clamping

Fiber Laser Cutting Machine

Electric CNC Press Brake

Vertical V Groove Slotting Machine

Sheet Metal Solutions Comparison

| Direct bending(Solution A) | Slotting bending(Solution B) | |||

| Deformation Mechanism | Outer layer stretch + inner layer compression | Material thinning at the notch eliminates compressive stress | ||

| Stress distribution | Stress concentration at the bending R angle | Stress is evenly distributed along the notch | ||

| Precision control | Angle deviation: ±0.5° - 1.5° (affected by material batch) | Angle deviation: ± 0.1° (after AI compensation) | ||

Sealing | There is a risk of leakage at the corners | Passed IP67 certification (new energy battery box) | ||

Structural strength | The R corner is the fracture source point | Hinge installation surface flatness <0.1mm | ||

External surface cracking 23% (thick plate) | External surface cracking ≤1% | |||

R angle wrinkles 18% | R angle wrinkles 0 | |||

Coating peeling 15% (sprayed parts) | Coating peeling 0.5% | |||

Production of simple brackets/covers (non-load-bearing parts); Material is low carbon steel (SPCC) and the plate thickness is less than 2mm; Product unit price is less than ¥20. | Processing sealed containers/load-bearing structural parts; Material: stainless steel/aluminum alloy; Product unit price > ¥50. | |||