High-Precision 80T 2000mm Electric CNC Press Brake|SYNTEC 8+1 Axis Control System

- Price

- US $4800-5000

- Model

- EP 80T2000

- MOQ

- 1 piece

Item specifics

- Color

- Dark Gray

- Bending angle

- 0-180 degrees

- Repeat positioning accuracy

- 0.01mm

- Bending length

- 1600mm-14000mm

- Main motor power

- 5.5KW -2x55KW

- Stroke

- 500mm-1000mm

Review

Description

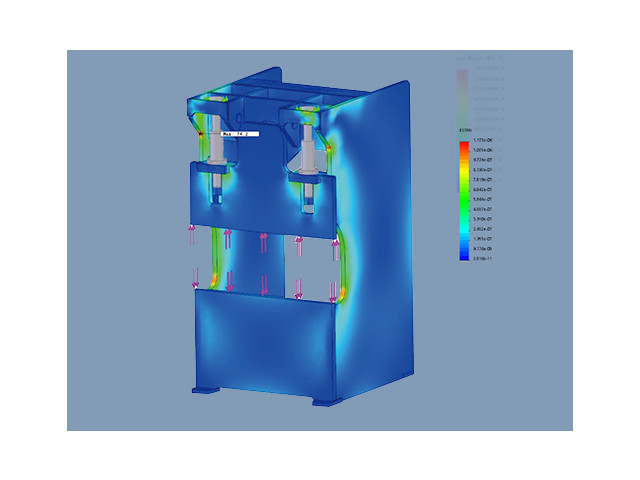

Mechanical Engineering Design of Electric Press Brake

RONGWEI have vast experience with R&D and designing components to very tighttolerances with SOLlDWORKS 3D CAD modelling techniques.

The design and analysis experiences of computer aidedengineering (CAE) used inthe heavy industry is novel forconventional company before prepare going to executethe fourthindustrial revolution.

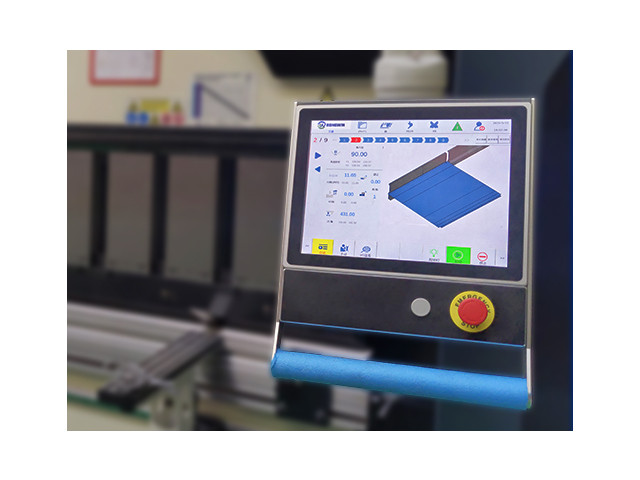

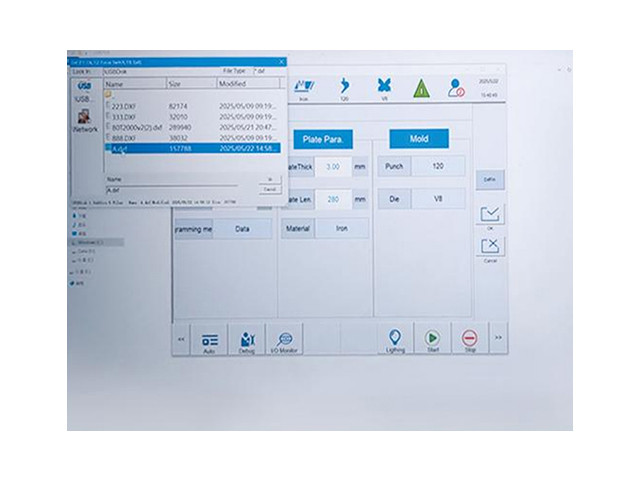

Electric Press Brake Syntec System

It is a CNC system specially developed for pure electric bending machines.

It provides an approachable programming method, making bending processing easier.

At the same time, the open interface is flexible and customized, and peripheral configurations can be expanded, such as auxiliary trolleys, making bending easier.

DXF import

2D Color Graphics

3D visualisation

Electric Press Brake SDKELI Laser Protection

Protection provides excellent optical performance while maintaining the highest productivity of CNC electric bending machines.

Electric Press Brake WILA AIRPOWER TOOLING SYSTEM

WILA hydraulic tool clamp, powered by hydraulic systems, deliver highclamping force and stability, designed for heavy-duty tooling andhigh-precision bending applications to meet rigorous industrial demands.

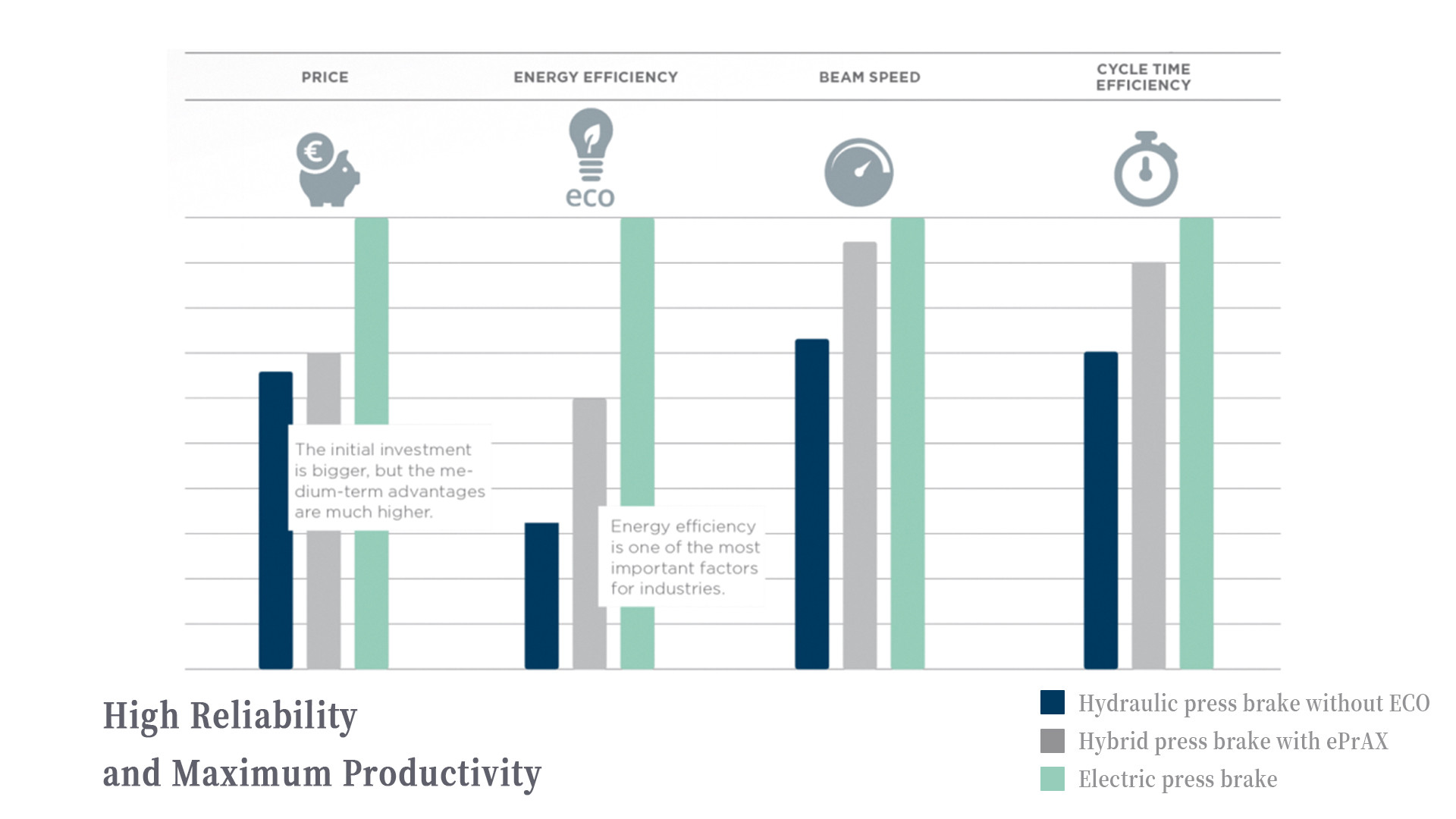

Electric Press Brake Servo electric technology

Providing high precision, high flexibility and consistently excellent results in the bending process. Our fully electric servo press brakes have low power consumption, low maintenance costs and do not require hydraulic oil or other hydraulic components to operate.

The features the advantages of high acceleration, deceleration and fast responsetimes of the servo-electric drive system, Compared to conventional press brakesconsiderable productivity increase can be reached,reduction of cycle timesby up to 35 % and more is the reality.

Time cycle comparison

High speed ram stroke by Ac Servo motor and ball serewdrive for fast approach, bending, and return speeds.

Bending time necessary to realize this 6 bend box - only machine time.