WF67K-M Electro-Hydraulic Servo CNC Press Brake | Precise and can bend to meet various needs

- Price

- US $4800-5000

- Model

- WF67K-M 80T/2500

- MOQ

- 1 piece

Item specifics

- color

- Red and black

- Machine Type

- Hybrid

- Workbench length (mm)

- 2500 mm

- Degree of automation

- Fully Automatic

- Degree of oldness

- New

- country of origin

- China

- Machinable materials

- Mild Steel,Stainless Steel,Aluminum

- Core selling point

- Energy saving

- Warranty

- 3 years

- Marketing Type

- New Product 2024

- Video factory inspection

- Provided

- Mechanical test report

- Provided

Review

Description

Why Choose Our Panel Bender? Key Features & Competitive Advantages

Pain Points

1. Higher initial investment cost

2. Maintenance challenges brought about by increased system complexity:

3. Higher skill requirements for operators

4. Potential servo systems have higher requirements for hydraulic oil

5. High requirements for power supply stability

6. Technology relies on imported core components

Selling Points

1. Excellent energy saving effect

2. Extremely high bending accuracy and repeat positioning accuracy

3. Excellent dynamic response speed and production efficiency

4. Low noise, low heat, more environmentally friendly

5. Powerful CNC system and intelligent functions

6. Equipment runs more smoothly and has a longer life

WF67K-M Hydraulic Servo CNC press brake Advantages

Advantage 1

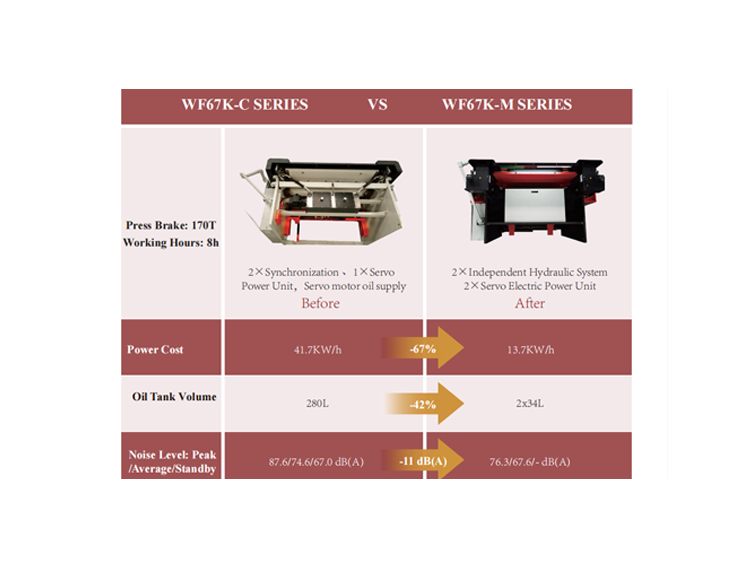

1. Energy revolution → Power consumption dropped from 41.7KWh to 13.7KWh (61% reduction), corresponding to the caption "-61%"

2. Hydraulic streamlining → Fuel tank reduced from 280L to 2×34L (42% reduction), eliminating resource waste

3. Silent breakthrough → Peak noise dropped from 87.6dB to 76.3dB (below 80dB industrial safety line)

4. Technology upgrade → Dual servo independent system (red frame technology module in the figure) replaces traditional single pump to achieve precise energy supply

Advantage 2

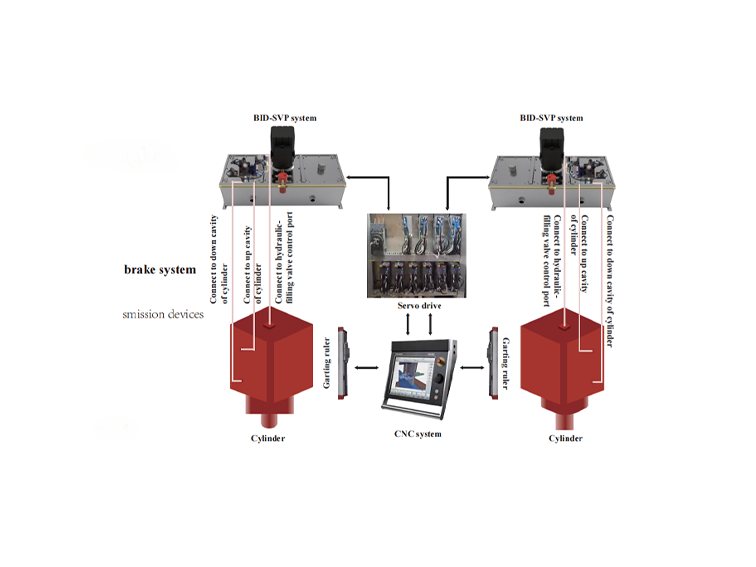

D-SVP high-performance dual-servo electro-hydraulic servo press brake system

D-SVP system advantages

Economy - 60% less electricity consumption compared to traditional transmission devices

High - 30% higher work efficiency (reduced cycle time)

Accurate - more accurate positioning accuracy, up to 5 um

Quiet - reduced noise, quieter machine operation

Less - very little hydraulic oil is used, only 30% of the traditional one

Easy - easier machine manufacturing, easier maintenance, lower failure rate

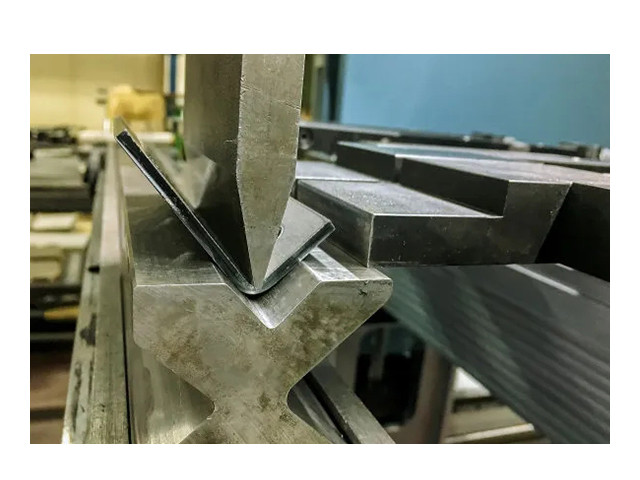

WF67K-M press brake Machine Details Display

Crowning table

Eliminate ±0.1° error, long workpiece bending straightness +300%, zero scrap rate

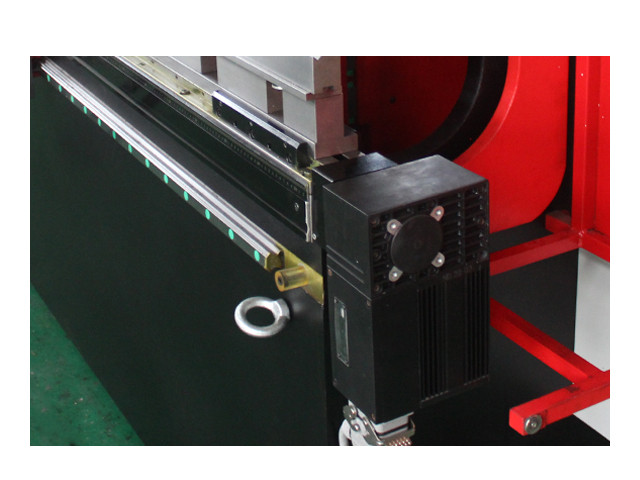

Grating ruler

Miniaturization + strong anti-fouling + maintenance-free, providing reliable position feedback for harsh industrial environments.

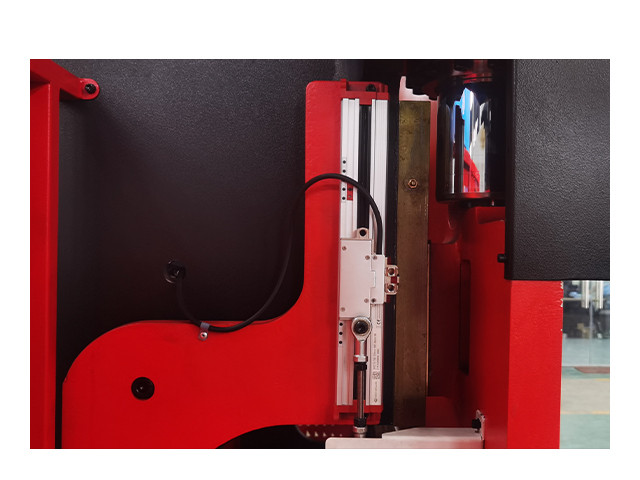

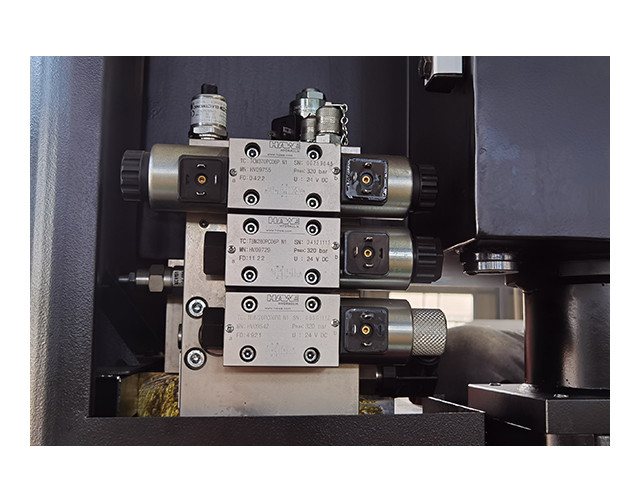

Hydraulic valve group

Integration + precise control + zero leakage design provide high reliability power distribution for complex hydraulic systems

WF67K-M press brake Machine Technical Parameters

Model

WF67K-series | Nominal

Pressure

(mm) | Bending

Length

(mm) | Poles

distance

(mm) | Throat

depth

(mm) | SlipperStroke(mm) | Max

Opening

Height

(mm) | Main

motor

(KW) | Travel

(mm) | Weight

(Kg) |

40T/1600 | 400 | 1600 | 1260 | 300 | 150 | 420 | 5.5 | 500 | 3800 |

63T/2500 | 630 | 2500 | 2000 | 300 | 150 | 420 | 5.5 | 500 | 4800 |

80T/2500 | 800 | 2500 | 2000 | 350 | 200 | 480 | 7.5 | 600 | 5700 |

|

100T/3200

|

1000

|

3200

|

2700 | 400 |

200/250

|

480/520 | 7.5 | 600 | 8500 |

|

100T/4000

|

1000

|

4000

|

3600 | 400 |

200/250

|

480/520 | 7.5 | 600 | 9300 |

|

160T/3200

|

1600

|

3200

|

2700 | 400 |

200/250

|

480/520 | 11 | 600 | 9500 |

160T/4000 | 1600 | 4000 | 3600 | 400 | 200/250 | 480/520 | 11 | 600 | 12100 |

|

200T/3200

|

2000

|

3200

|

2700 | 400 |

250

|

530 | 15 | 600 | 11000 |

200T/4000 | 2000 | 4000 | 3600 | 400 | 250 | 530 | 15 | 600 | 13500 |

250T/3200 | 2500 | 3200 | 2700 | 400 | 250 | 530 | 18.5 | 600 | 13000 |

250T/4000 | 2500 | 4000 | 3600 | 400 | 250 | 530 | 18.5 | 600 | 15500 |

250T/5000 | 2500 | 5000 | 4300 | 400 | 250 | 530 | 22 | 600 | 18000 |

300T/3200 | 3000 | 3200 | 2700 | 400 | 300 | 580 | 22 | 600 | 19200 |

300T/4000 | 3000 | 4000 | 3600 | 400 | 300 | 580 | 22 | 600 | 22500 |

400T/4000 | 4000 | 4000 | 3600 | 400 | 320 | 580 | 30 | 600 | 25500 |

400T/5000 | 4000 | 5000 | 4000 | 400 | 320 | 580 | 30 | 600 | 31500 |

500T/4000 | 5000 | 4000 | 3500 | 500 | 320 | 590 | 37 | 600 | 34500 |

500T/5000 | 5000 | 5000 | 4000 | 500 | 320 | 590 | 37 | 800 | 43500 |

500T/6000 | 5000 | 6000 | 5000 | 500 | 320 | 590 | 37 | 800 | 53000 |

600T/5000 | 6000 | 5000 | 4000 | 500 | 320 | 640 | 45 | 800 | 57000 |

600T/6000 | 6000 | 6000 | 5000 | 500 | 320 | 640 | 45 | 800 | 68000 |

600T/7000 | 6000 | 7000 | 6000 | 500 | 320 | 640 | 45 | 800 | 79000 |

800T/6000 | 8000 | 6000 | 5000 | 600 | 400 | 800 | 55 | 800 | 90000 |

800T/7000 | 8000 | 7000 | 6000 | 600 | 400 | 800 | 55 | 800 | 105000 |

800T/8000 | 8000 | 8000 | 7000 | 600 | 400 | 800 | 55 | 800 | 120000 |

1000T/6000 | 10000 | 6000 | 5000 | 600 | 400 | 800 | 2x37 | 800 | 100000 |

1000T/8000 | 10000 | 8000 | 6900 | 700 | 400 | 800 | 2x37 | 800 | 130000 |

1000T/10000 | 10000 | 10000 | 8000 | 700 | 400 | 800 | 2x37 | 800 | 150000 |

1200T/6000 | 12000 | 6000 | 4220 | 700 | 400 | 1000 | 2x45 | 1000 | 130000 |

1200T/7000 | 12000 | 7000 | 5220 | 700 | 400 | 1000 | 2x45 | 1000 | 160000 |

1600T/6000 | 16000 | 6000 | 4900 | 700 | 400 | 1000 | 2x55 | 1000 | 150000 |

1600T/7000 | 16000 | 7000 | 5900 | 700 | 400 | 1000 | 2x55 | 1000 | 170000 |

1600T/8000 | 16000 | 8000 | 6900 | 700 | 400 | 1000 | 2x55 | 1000 | 190000 |

1600T/10000 | 16000 | 10000 | 8000 | 700 | 400 | 1000 | 2x55 | 1000 | 210000 |

2000T/8000 | 20000 | 8000 | 6200 | 700 | 400 | 1000 | 2x55 | 1000 | 260000 |

2000T/10000 | 20000 | 10000 | 8000 | 700 | 400 | 1000 | 2x55 | 1000 | 290000 |

2000T/12000 | 20000 | 12000 | 9050 | 700 | 400 | 1000 | 2x55 | 1000 | 320000 |

2000T/14000 | 20000 | 14000 | 11000 | 700 | 400 | 1000 | 2x55 | 1000 | 350000 |

3000T/8000 | 30000 | 8000 | 6200 | 700 | 400 | 1000 | 2x55 | 1000 | / |

3000T/10000 | 30000 | 10000 | 8000 | 700 | 400 | 1000 | 2x55 | 1000 | / |

3000T/12000 | 30000 | 12000 | 9050 | 700 | 400 | 1000 | 2x55 | 1000 | / |

3000T/14000 | 30000 | 14000 | 11000 | 700 | 400 | 1000 | 2x55 | 1000 | / |

Parameters within this range reflect the wide applicability of the WF67K-Mseries press brakes in different application scenarios, from small and medium-sized precision processing to large-scale industrial manufacturing.

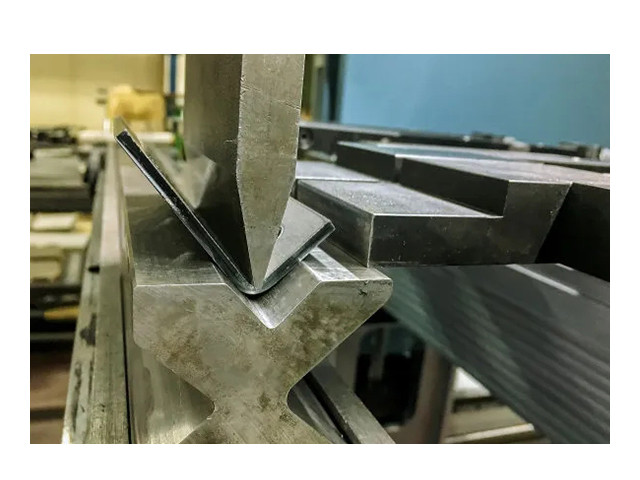

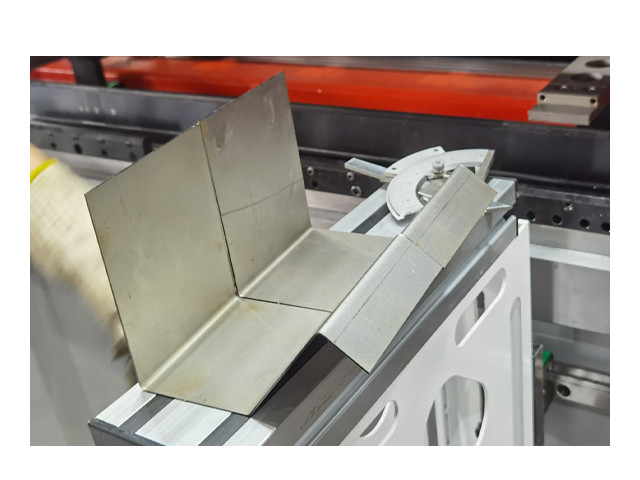

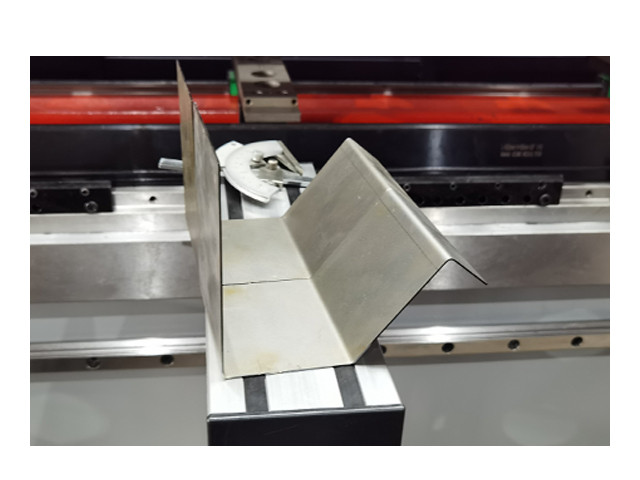

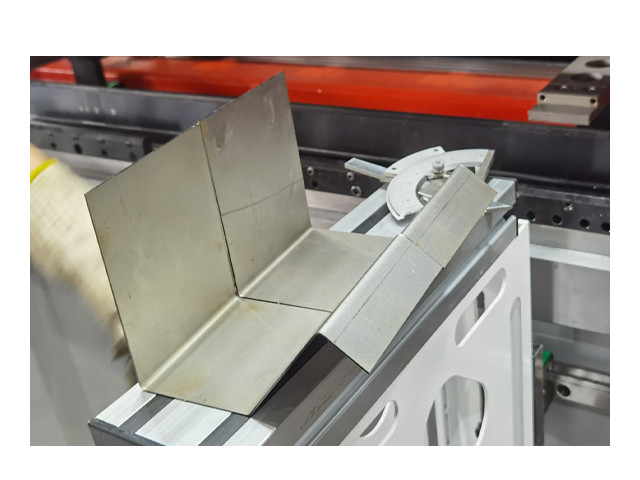

Typical workpieces

Customer Reviews

WF67K-M press brake Machine FAQ

What is the WF67K-M press brake?

The WF67K-M series is a Hybrid CNC Press Brake that combines hydraulic and electric drive systems to deliver high precision, energy efficiency, and versatile bending capabilities for a wide range of metal sheet applications.

What are the key features of the WF67K-M press brake?

1.Hybrid Drive System: Combines hydraulic and electric components for better energy efficiency and faster operations.

2.Advanced CNC Control: Equipped with a CNC system for accurate, easy-to-use multi-axis control (X, Y1, Y2, R, Z1, Z2).

3.High Precision: Delivers consistent, high-quality bending results across various materials and thicknesses.

4.Durability: Built to last with high-quality materials and a robust frame that can handle heavy-duty production.

5.Safety Features: Includes safety light curtains, emergency stop buttons, and protective shields for operator protection.

What bending capacities are available with the WF67K-M?

The WF67K-M series offers different tonnages and bending lengths to meet various needs:

1.Maximum Bending Force: Up to 250 tons.

2.Bending Length: Options available up to 4100mm or more.

Customization: Available in different sizes and configurations based on production requirements.