RONGWIN Customizable Tandem press brake | Electro-Hydraulic CNC Press Brake

- Price

- US $5000-4800

- Model

- Tandem press brake|Electro-hydraulic CNC Press Brake

- MOQ

- 1 piece

Item specifics

- color

- White Gray

- Machine Type

- Synchronized

- Workbench length (mm)

- 4000 mm

- Degree of automation

- Fully Automatic

- Degree of oldness

- New

- country of origin

- China

- Machinable materials

- Brass / Copper stainless steel

- Core selling point

- High Productivity

- Warranty

- 3 years

- Mechanical test report

- Provided

- Video factory inspection

- Provided

- Core component warranty period

- 1 Year

Review

Description

Tandem press brake

Electro-hydraulic CNC Press Brake

High Precision Press Brake Machine

Our large-tonnage CNC bending machine uses a dual-servo hybrid oil-electric system.This innovation enables the machine to achieve dual-machine operation when processing long workpieces, and also supports single-machine operation. The action is stable and reliable,and the energy-saving effect is more prominent.

Application Scenario

Advantages

Feature 1

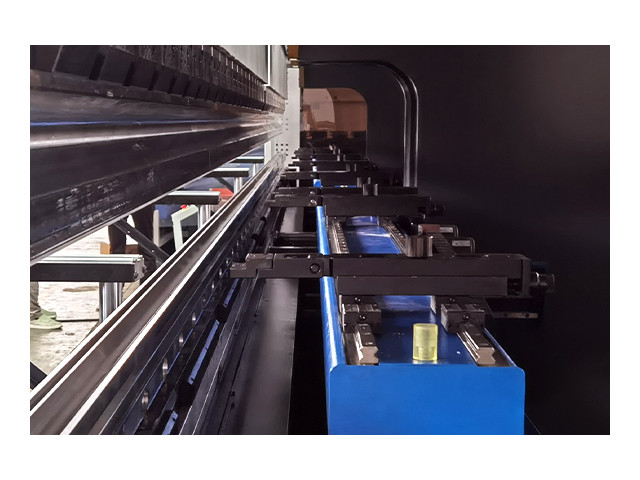

The double-machine linkage bending machine uses hydraulic cylinders of the same specifications, combined with double-machine linkage synchronization devices and advanced CNC systems to achieve synchronous bending between the two machines.

Feature 2

Synchronous and precise control: With the help of the dual-machine linkage synchronization device and the real-time feedback and adjustment of the CNC system, the synchronous operation of the machine is guaranteed during the entire bending process, greatly reducing the deviation.

Load balancing optimization: The dual-machine design evenly distributes the processing pressure, effectively Expanding the processing range: The dual-machine linkage is suitable Intelligent operation: The CNC system supports a variety of preset processing programs and real-time adjustments Efficient production capacity: The dual-machine linkage structure enables the processing size of the plate to be larger

WF67K press brake Machine Technical Parameters

WF67K press brake series offers a variety of models, covering a variety of needs from small to large, the specific technical parameters range as follows:

Model

WF67K-series | Nominal

Pressure

(mm) | Bending

Length

(mm) | Poles

distance

(mm) | Throat

depth

(mm) | SlipperStroke(mm) | Max

Opening

Height

(mm) | Main

motor

(KW) | Travel

(mm) | Weight

(Kg) |

40T/1600 | 400 | 1600 | 1260 | 300 | 150 | 420 | 5.5 | 500 | 3800 |

63T/2500 | 630 | 2500 | 2000 | 300 | 150 | 420 | 5.5 | 500 | 4800 |

80T/2500 | 800 | 2500 | 2000 | 350 | 200 | 480 | 7.5 | 600 | 5700 |

|

100T/3200

|

1000

|

3200

|

2700 | 400 |

200/250

|

480/520 | 7.5 | 600 | 8500 |

|

100T/4000

|

1000

|

4000

|

3600 | 400 |

200/250

|

480/520 | 7.5 | 600 | 9300 |

|

160T/3200

|

1600

|

3200

|

2700 | 400 |

200/250

|

480/520 | 11 | 600 | 9500 |

160T/4000 | 1600 | 4000 | 3600 | 400 | 200/250 | 480/520 | 11 | 600 | 12100 |

|

200T/3200

|

2000

|

3200

|

2700 | 400 |

250

|

530 | 15 | 600 | 11000 |

200T/4000 | 2000 | 4000 | 3600 | 400 | 250 | 530 | 15 | 600 | 13500 |

250T/3200 | 2500 | 3200 | 2700 | 400 | 250 | 530 | 18.5 | 600 | 13000 |

250T/4000 | 2500 | 4000 | 3600 | 400 | 250 | 530 | 18.5 | 600 | 15500 |

250T/5000 | 2500 | 5000 | 4300 | 400 | 250 | 530 | 22 | 600 | 18000 |

300T/3200 | 3000 | 3200 | 2700 | 400 | 300 | 580 | 22 | 600 | 19200 |

300T/4000 | 3000 | 4000 | 3600 | 400 | 300 | 580 | 22 | 600 | 22500 |

400T/4000 | 4000 | 4000 | 3600 | 400 | 320 | 580 | 30 | 600 | 25500 |

400T/5000 | 4000 | 5000 | 4000 | 400 | 320 | 580 | 30 | 600 | 31500 |

500T/4000 | 5000 | 4000 | 3500 | 500 | 320 | 590 | 37 | 600 | 34500 |

500T/5000 | 5000 | 5000 | 4000 | 500 | 320 | 590 | 37 | 800 | 43500 |

500T/6000 | 5000 | 6000 | 5000 | 500 | 320 | 590 | 37 | 800 | 53000 |

600T/5000 | 6000 | 5000 | 4000 | 500 | 320 | 640 | 45 | 800 | 57000 |

600T/6000 | 6000 | 6000 | 5000 | 500 | 320 | 640 | 45 | 800 | 68000 |

600T/7000 | 6000 | 7000 | 6000 | 500 | 320 | 640 | 45 | 800 | 79000 |

800T/6000 | 8000 | 6000 | 5000 | 600 | 400 | 800 | 55 | 800 | 90000 |

800T/7000 | 8000 | 7000 | 6000 | 600 | 400 | 800 | 55 | 800 | 105000 |

800T/8000 | 8000 | 8000 | 7000 | 600 | 400 | 800 | 55 | 800 | 120000 |

1000T/6000 | 10000 | 6000 | 5000 | 600 | 400 | 800 | 2x37 | 800 | 100000 |

1000T/8000 | 10000 | 8000 | 6900 | 700 | 400 | 800 | 2x37 | 800 | 130000 |

1000T/10000 | 10000 | 10000 | 8000 | 700 | 400 | 800 | 2x37 | 800 | 150000 |

1200T/6000 | 12000 | 6000 | 4220 | 700 | 400 | 1000 | 2x45 | 1000 | 130000 |

1200T/7000 | 12000 | 7000 | 5220 | 700 | 400 | 1000 | 2x45 | 1000 | 160000 |

1600T/6000 | 16000 | 6000 | 4900 | 700 | 400 | 1000 | 2x55 | 1000 | 150000 |

1600T/7000 | 16000 | 7000 | 5900 | 700 | 400 | 1000 | 2x55 | 1000 | 170000 |

1600T/8000 | 16000 | 8000 | 6900 | 700 | 400 | 1000 | 2x55 | 1000 | 190000 |

1600T/10000 | 16000 | 10000 | 8000 | 700 | 400 | 1000 | 2x55 | 1000 | 210000 |

2000T/8000 | 20000 | 8000 | 6200 | 700 | 400 | 1000 | 2x55 | 1000 | 260000 |

2000T/10000 | 20000 | 10000 | 8000 | 700 | 400 | 1000 | 2x55 | 1000 | 290000 |

2000T/12000 | 20000 | 12000 | 9050 | 700 | 400 | 1000 | 2x55 | 1000 | 320000 |

2000T/14000 | 20000 | 14000 | 11000 | 700 | 400 | 1000 | 2x55 | 1000 | 350000 |

3000T/8000 | 30000 | 8000 | 6200 | 700 | 400 | 1000 | 2x55 | 1000 | / |

3000T/10000 | 30000 | 10000 | 8000 | 700 | 400 | 1000 | 2x55 | 1000 | / |

3000T/12000 | 30000 | 12000 | 9050 | 700 | 400 | 1000 | 2x55 | 1000 | / |

3000T/14000 | 30000 | 14000 | 11000 | 700 | 400 | 1000 | 2x55 | 1000 | / |

Parameters within this range reflect the wide applicability of the WF67K-E series press brakes in different application scenarios, from small and medium-sized precision processing to large-scale industrial manufacturing.

WF67K press brake Machine Details Display

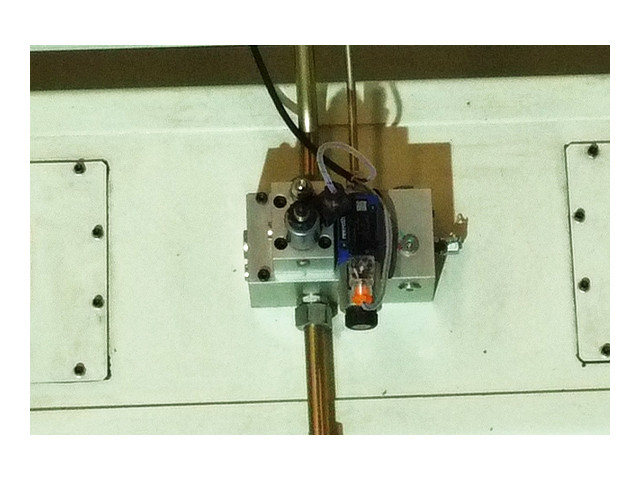

Hydraulic valve group

Main Motor

Stop finger

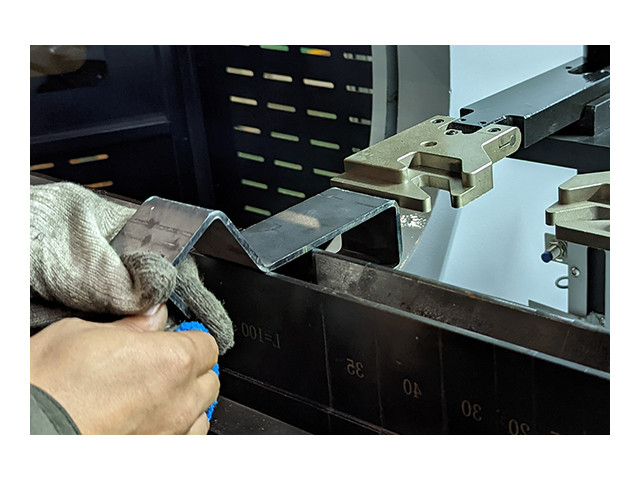

Fast Clamp

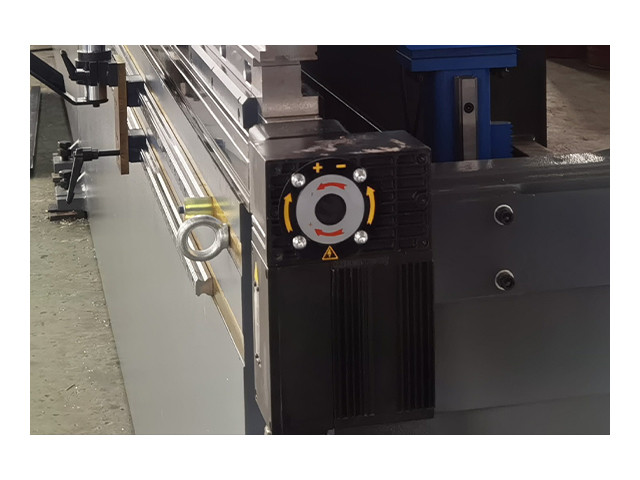

Crowning table

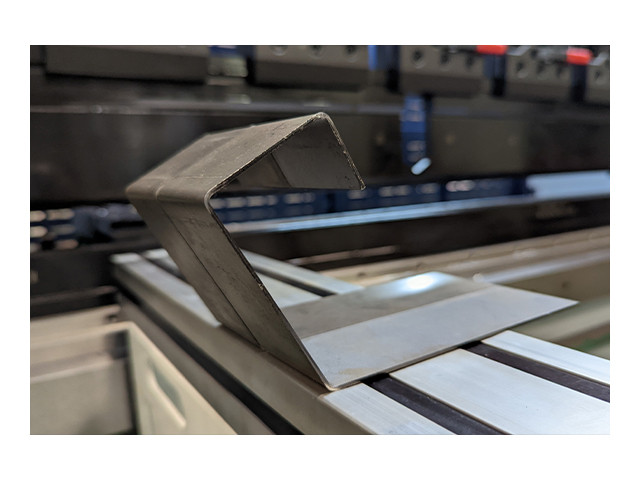

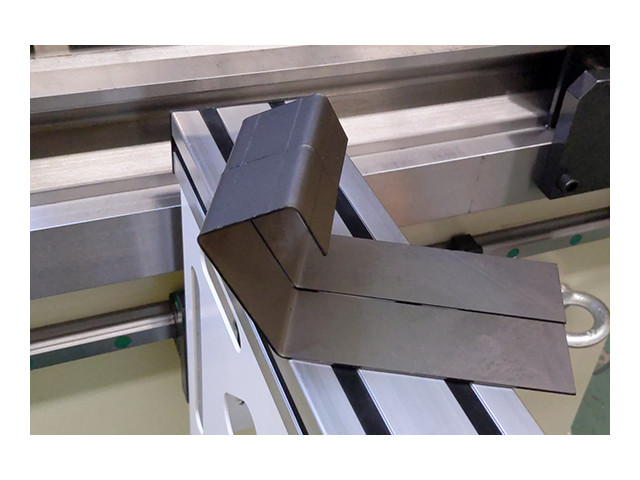

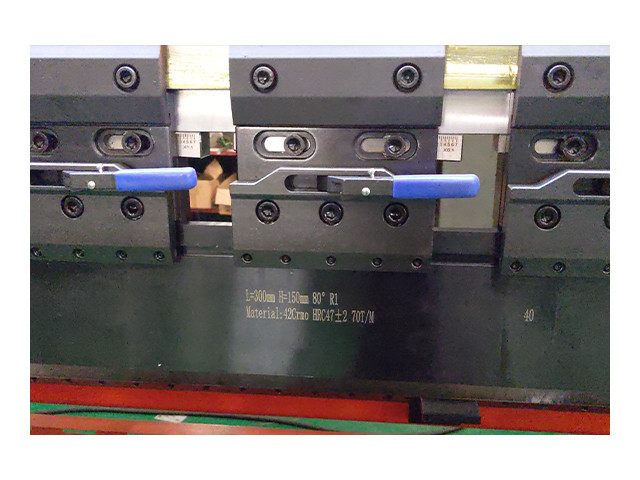

Press brake tooling

Front Support

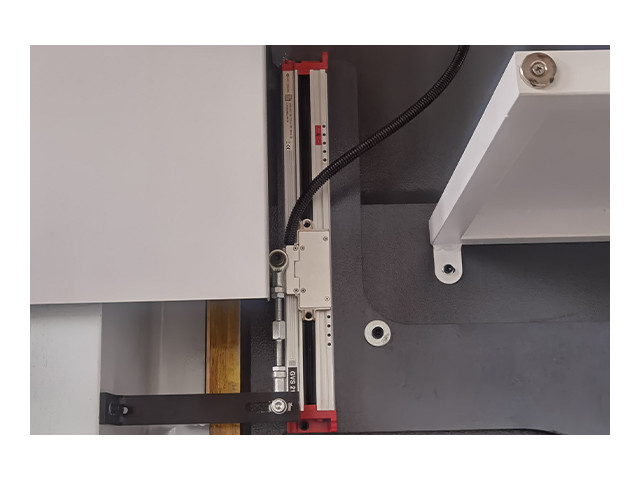

Grating Ruler

Tandem press brake

Electro-hydraulic CNC Press Brake Machine FAQ

What is a tandem press brake?

A tandem press brake is a system where two or more press brakes work together in synchronization to handle larger workpieces, providing extended bending lengths and higher tonnage capacities.

How does the electro-hydraulic synchronization work?

It uses advanced CNC systems to synchronize the hydraulic cylinders of multiple press brakes, ensuring precise and uniform bending performance across all units.

What materials can be processed with a tandem press brake?

Tandem press brakes can process various materials, including carbon steel, stainless steel, aluminum, and other metal sheets requiring precise and complex bending.

What industries benefit from tandem press brakes?

They are commonly used in shipbuilding, construction, aerospace, heavy machinery, and other industries that require large or heavy-duty components.