RONGWIN WF67K-E Press Brake WF67K-E | Support OEM & ODM

- Price

- US $46770-11417

- Model

- WF67K-E 200T4000

- MOQ

- 1 piece

Item specifics

- Color

- Blue and White

- Machine Type

- Synchronized

- Workbench length (mm)

- 4000 mm

- Degree of automation

- Fully Automatic

- Degree of oldness

- New

- country of origin

- China

- Machinable materials

- Brass/ Copper,stainless steel,ALLO

- Core selling point

- High Productivity

- Warranty

- 3 years

- Applicable industries

- Hotels,Garment Shops,United States

- Marketing Type

- Hot Product 2024

- Mechanical test report

- Provided

- Video factory inspection

- Provided

- Core component warranty period

- 1 Year

Review

Description

WF67K-E Press Brake Introduction

High-Precision Hydraulic CNC Press Brake with Mechanical Crowning and Reliable Performance

Adopt overall welding,after the aging treatment,then adopt overall processing methods to ensure the accuracy and reliability of the whole machine.

Standard 4+1 axis; Stable performance, High precision of angle and size; With Mechanical crowning system, work better long work piece.

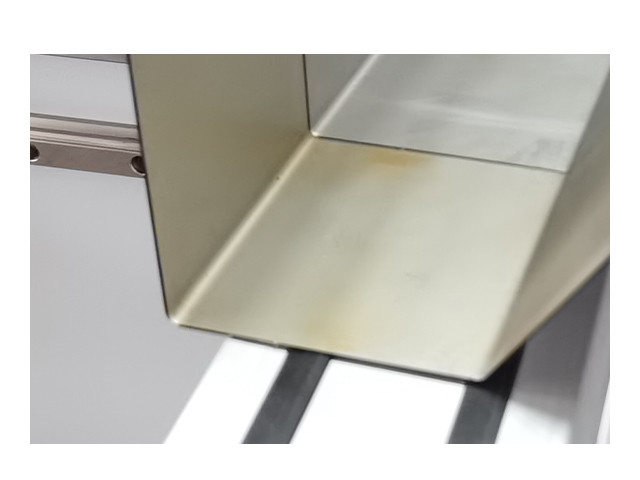

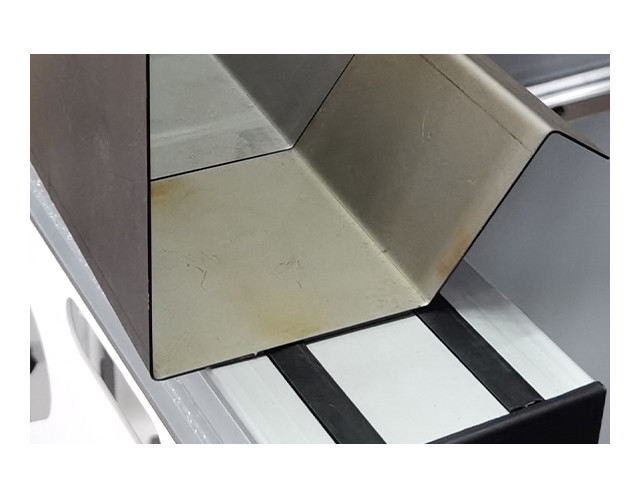

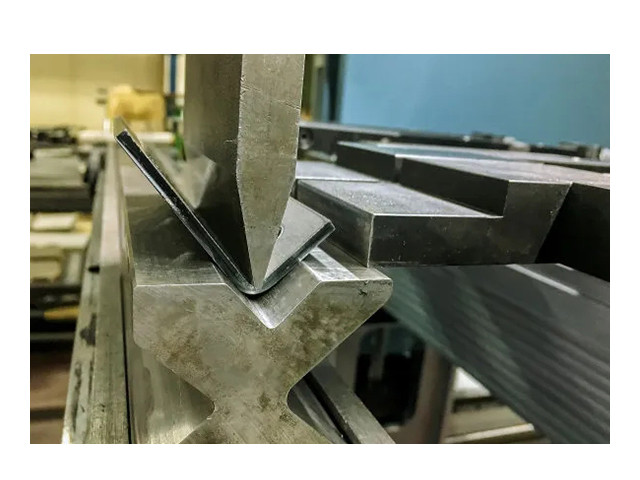

WF67K-E Press Brake Application Scenario

WF67K-E Press Brake Introduction Advantages

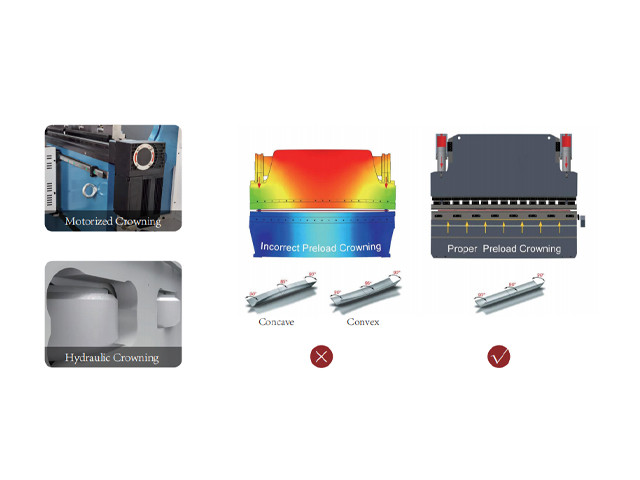

Feature 1

CNC Crowning

The stress can cause the ram and worktable some deformation during the process of bending; the CNC crowning can make relevant

compensation to the ram deformation, which improves the precision of press brake by a wide margin. lt is specially applied to make

some high precision products such as stainless steel.

Feature 2

DELEM DA69T (8+1 Axis)

1.3D and 2D graphical touch screen programming mode

2.3D visualisation in simulation and production

3.17" high resolution colour TFT

4.Full Windows application suite

5.Delem Modusys compatibility (module scalability and adaptivity)

6.USB, peripheral interfacing

7.User specific application support within the control's multitasking

environment

8.Sensor bending & correction interface

9.Profile-T3D offline software

WF67K-E press brake Machine Technical Parameters

WF67K-E press brake series offers a variety of models, covering a variety of needs from small to large, the specific technical parameters range as follows:

Model

WF67K-series | Nominal

Pressure

(mm) | Bending

Length

(mm) | Poles

distance

(mm) | Throat

depth

(mm) | SlipperStroke(mm) | Max

Opening

Height

(mm) | Main

motor

(KW) | Travel

(mm) | Weight

(Kg) |

40T/1600 | 400 | 1600 | 1260 | 300 | 150 | 420 | 5.5 | 500 | 3800 |

63T/2500 | 630 | 2500 | 2000 | 300 | 150 | 420 | 5.5 | 500 | 4800 |

80T/2500 | 800 | 2500 | 2000 | 350 | 200 | 480 | 7.5 | 600 | 5700 |

|

100T/3200

|

1000

|

3200

|

2700 | 400 |

200/250

|

480/520 | 7.5 | 600 | 8500 |

|

100T/4000

|

1000

|

4000

|

3600 | 400 |

200/250

|

480/520 | 7.5 | 600 | 9300 |

|

160T/3200

|

1600

|

3200

|

2700 | 400 |

200/250

|

480/520 | 11 | 600 | 9500 |

160T/4000 | 1600 | 4000 | 3600 | 400 | 200/250 | 480/520 | 11 | 600 | 12100 |

|

200T/3200

|

2000

|

3200

|

2700 | 400 |

250

|

530 | 15 | 600 | 11000 |

200T/4000 | 2000 | 4000 | 3600 | 400 | 250 | 530 | 15 | 600 | 13500 |

250T/3200 | 2500 | 3200 | 2700 | 400 | 250 | 530 | 18.5 | 600 | 13000 |

250T/4000 | 2500 | 4000 | 3600 | 400 | 250 | 530 | 18.5 | 600 | 15500 |

250T/5000 | 2500 | 5000 | 4300 | 400 | 250 | 530 | 22 | 600 | 18000 |

300T/3200 | 3000 | 3200 | 2700 | 400 | 300 | 580 | 22 | 600 | 19200 |

300T/4000 | 3000 | 4000 | 3600 | 400 | 300 | 580 | 22 | 600 | 22500 |

400T/4000 | 4000 | 4000 | 3600 | 400 | 320 | 580 | 30 | 600 | 25500 |

400T/5000 | 4000 | 5000 | 4000 | 400 | 320 | 580 | 30 | 600 | 31500 |

500T/4000 | 5000 | 4000 | 3500 | 500 | 320 | 590 | 37 | 600 | 34500 |

500T/5000 | 5000 | 5000 | 4000 | 500 | 320 | 590 | 37 | 800 | 43500 |

500T/6000 | 5000 | 6000 | 5000 | 500 | 320 | 590 | 37 | 800 | 53000 |

600T/5000 | 6000 | 5000 | 4000 | 500 | 320 | 640 | 45 | 800 | 57000 |

600T/6000 | 6000 | 6000 | 5000 | 500 | 320 | 640 | 45 | 800 | 68000 |

600T/7000 | 6000 | 7000 | 6000 | 500 | 320 | 640 | 45 | 800 | 79000 |

800T/6000 | 8000 | 6000 | 5000 | 600 | 400 | 800 | 55 | 800 | 90000 |

800T/7000 | 8000 | 7000 | 6000 | 600 | 400 | 800 | 55 | 800 | 105000 |

800T/8000 | 8000 | 8000 | 7000 | 600 | 400 | 800 | 55 | 800 | 120000 |

1000T/6000 | 10000 | 6000 | 5000 | 600 | 400 | 800 | 2x37 | 800 | 100000 |

1000T/8000 | 10000 | 8000 | 6900 | 700 | 400 | 800 | 2x37 | 800 | 130000 |

1000T/10000 | 10000 | 10000 | 8000 | 700 | 400 | 800 | 2x37 | 800 | 150000 |

1200T/6000 | 12000 | 6000 | 4220 | 700 | 400 | 1000 | 2x45 | 1000 | 130000 |

1200T/7000 | 12000 | 7000 | 5220 | 700 | 400 | 1000 | 2x45 | 1000 | 160000 |

1600T/6000 | 16000 | 6000 | 4900 | 700 | 400 | 1000 | 2x55 | 1000 | 150000 |

1600T/7000 | 16000 | 7000 | 5900 | 700 | 400 | 1000 | 2x55 | 1000 | 170000 |

1600T/8000 | 16000 | 8000 | 6900 | 700 | 400 | 1000 | 2x55 | 1000 | 190000 |

1600T/10000 | 16000 | 10000 | 8000 | 700 | 400 | 1000 | 2x55 | 1000 | 210000 |

2000T/8000 | 20000 | 8000 | 6200 | 700 | 400 | 1000 | 2x55 | 1000 | 260000 |

2000T/10000 | 20000 | 10000 | 8000 | 700 | 400 | 1000 | 2x55 | 1000 | 290000 |

2000T/12000 | 20000 | 12000 | 9050 | 700 | 400 | 1000 | 2x55 | 1000 | 320000 |

2000T/14000 | 20000 | 14000 | 11000 | 700 | 400 | 1000 | 2x55 | 1000 | 350000 |

3000T/8000 | 30000 | 8000 | 6200 | 700 | 400 | 1000 | 2x55 | 1000 | / |

3000T/10000 | 30000 | 10000 | 8000 | 700 | 400 | 1000 | 2x55 | 1000 | / |

3000T/12000 | 30000 | 12000 | 9050 | 700 | 400 | 1000 | 2x55 | 1000 | / |

3000T/14000 | 30000 | 14000 | 11000 | 700 | 400 | 1000 | 2x55 | 1000 | / |

Parameters within this range reflect the wide applicability of the WF67K-E series press brakes in different application scenarios, from small and medium-sized precision processing to large-scale industrial manufacturing.

WF67K-E press brake Machine Details Display

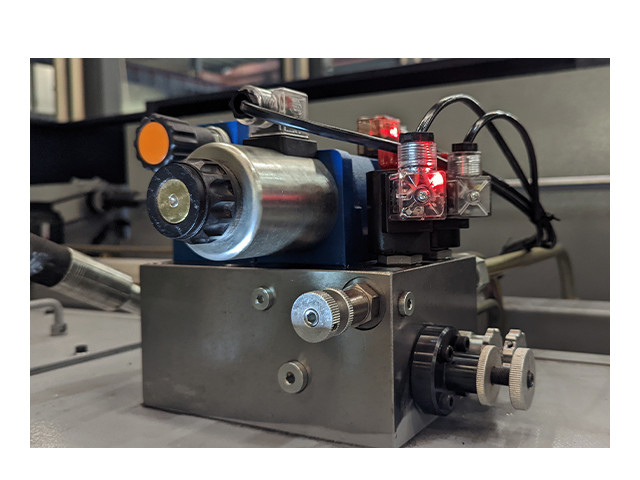

Hydraulic valve group

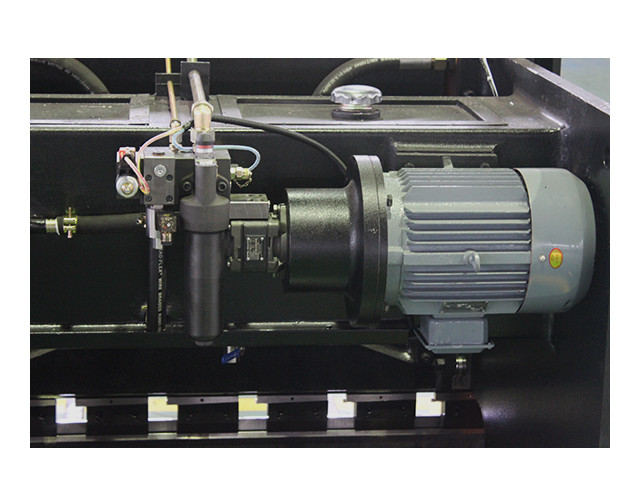

Main motor

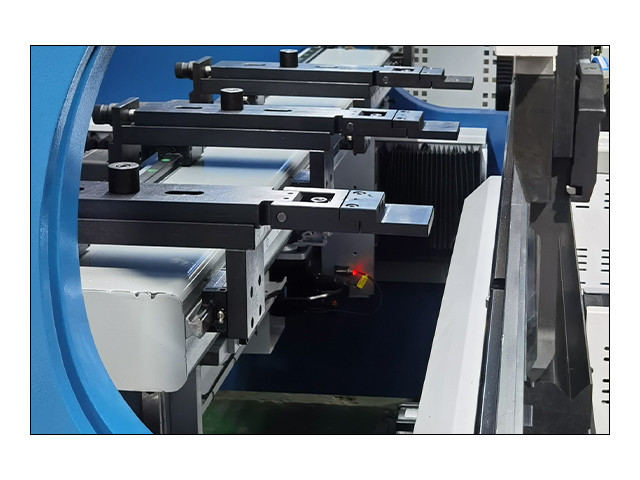

Stop finger

Fast clamp

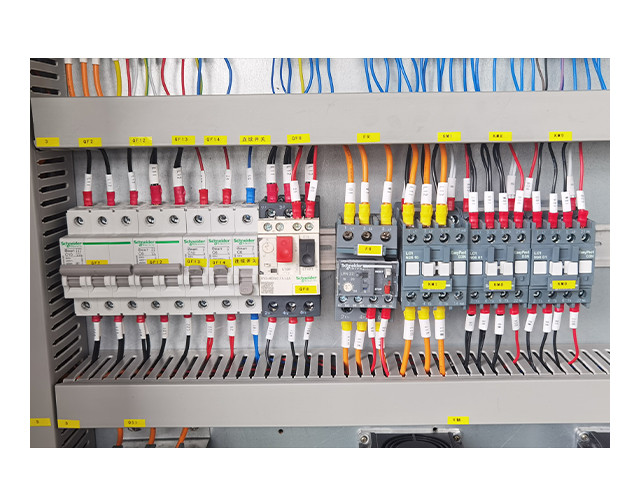

Schneider electric

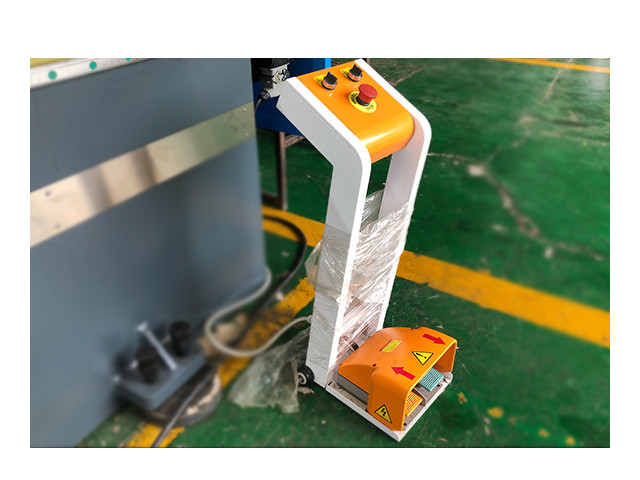

Foot switch

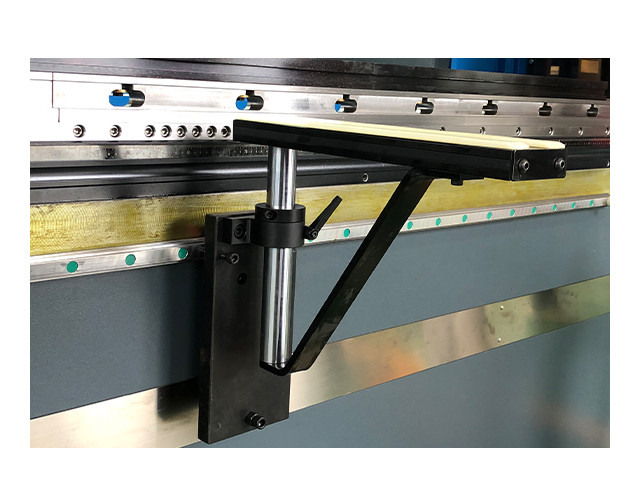

Front support

Grating ruler

WF67K-E press brake Machine FAQ

What are the main advantages of the WF67K-E series electro-hydraulic synchronization system?

Electro-hydraulic

What types of materials can the WF67K-E press brake process?

WF67K-E series is suitable for bending various metal plates such as stainless steel, carbon steel, aluminum, etc.

What are the main features of the WF67K-E bending machine?

Key features include:

Electro-hydraulic synchronizer

CNC control system for easy programming and operation

Automatic backgauge and crowning options for precise bending

Energy-saving operation with minimal power consumption

Advanced safety features such as light curtains and emergency stops