RONGWIN WD67Y High-Precision Press Brake machine | Easy to Operate

- Price

- US $10000-7500

- Model

- WD67Y-63T/1600

- MOQ

- 1 piece

Item specifics

- color

- Red and black

- Machine Type

- Synchronized

- Workbench length (mm)

- 1600 mm

- Degree of automation

- Semi-automatic

- Degree of oldness

- New

- country of origin

- China

- Machinable materials

- Brass/ Copper, Stainless steel, Carbon steel

- Core selling point

- High Productivity

- Warranty

- 3 years

- Applicable industries

- Hotels, Garment Shops

- Marketing Type

- Hot Product

- Mechanical test report

- Provided

- Video factory inspection

- Provided

- Core component warranty period

- 1 Year

Review

Description

WD67Y-series NC Type Hydraulic Press Brake

High Precision Press Brake Machine

RONGWIN Estun E21 NC press brake machine is designed by the advanced technology,which has the advantages of easy operation, economical and practical.Although it is an NC bending machine,the effect is comparable to a CNC press brake. The E21 bending machine is provided digital display for the positions of rear stopper and gliding block, as well as prompting function for soft limit of X/Y shaft and one-way positioning clearance.

Rear stopper and upper gliding block are both fitted with coders, for a more accurate display for positions of rear stopper and upper gliding block in cooperation with digital display system, thus to further increase the operating precision of this machine.

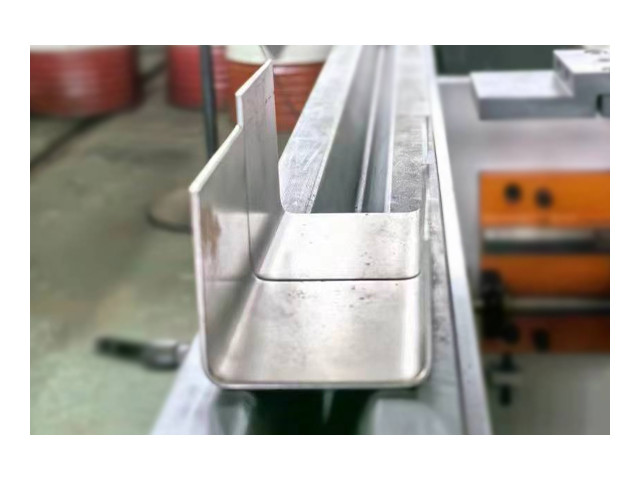

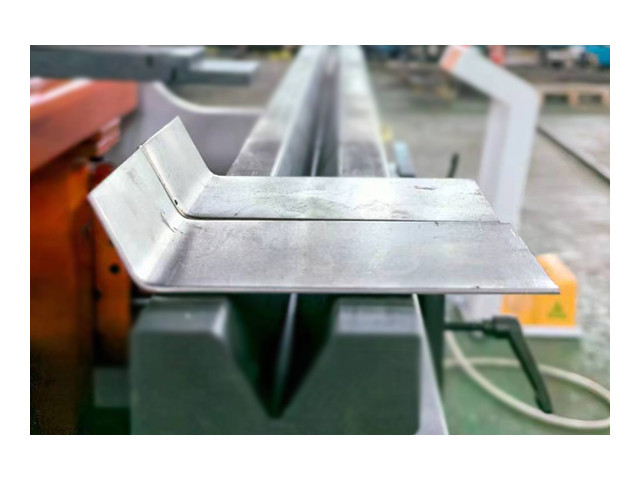

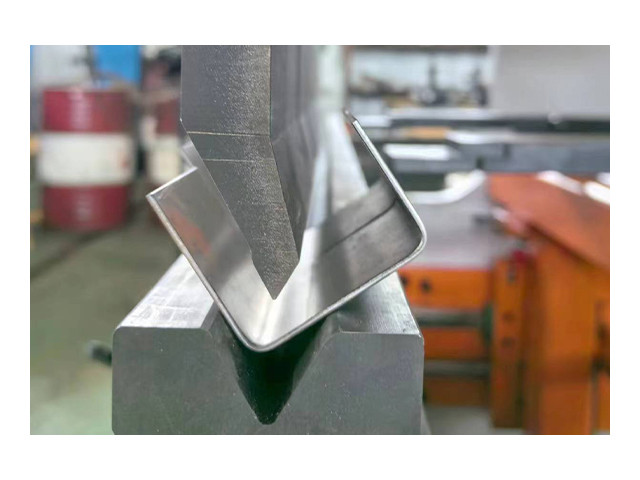

Application Scenario

Advantages

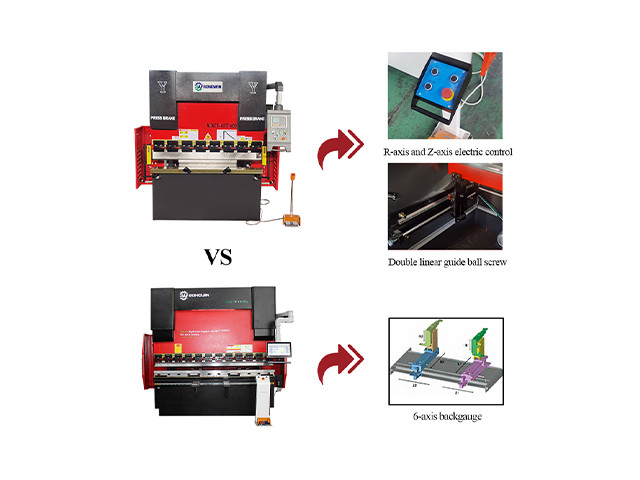

Feature 1

The backgauge feature of the WD67Y series CNC hydraulic press brakes provides a level of performance comparable to that of advanced electro-hydraulic systems with 6+1 axis control, providing precise positioning and adjustments for complex bending tasks. This feature enables users to achieve high-quality results while reducing costs, making it an effective solution for manufacturers seeking high-quality bending

Feature 2

Estun E21 Control System

1.Back gauge and block control

2.Control for generalAC motors, frequency converter

3.Intelligent positioning

4.Stock counter

5.Holding/decompression time setting

6.Program memory of up to 40 programs up to 25 steps per program

7.One side positioning

8.Retract function

9.One key backup/restore of parameters

10.mm/Inch

11.Chinese/Eng

WD67Y press brake Machine Technical Parameters

WD67Y press brake series offers a variety of models, covering a variety of needs from small to large, the specific technical parameters range as follows:

Parameters within this range reflect the wide applicability of the WD67Y series press brakes in different application scenarios, from small and medium-sized precision processing to large-scale industrial manufacturing.

Model torsion bar series | Nominal

Pressure

(mm) | Workbench

length

(mm) | Poles

distance

(mm) | Throat

depth

(mm) | Slipper

Stroke

(mm) | MaxOpen

(mm) | Main

motor

(KW) | Dimension

(L×W×H)(mm) |

30T/1600 | 300 | 1600 | 1250 | 170 | 90 | 195 | 3 | 1600×920×1660 |

30T/2050 | 300 | 2050 | 1450 | 170 | 90 | 195 | 3 | 2050×920×1660 |

40T/2200 | 400 | 2200 | 1850 | 245 | 100 | 330 | 5.5 | 2260×1200×1950 |

40T/2500 | 400 | 2500 | 2150 | 245 | 100 | 330 | 5.5 | 2560×1200×1950 |

50T/2500 | 500 | 2500 | 2150 | 245 | 100 | 330 | 5.5 | 2560×1200×1950 |

63T/2500 | 630 | 2500 | 2000 | 250 | 120 | 350 | 5.5 | 2560×1350×2120 |

80T/2500 | 800 | 2500 | 2000 | 250 | 120 | 350 | 7.5 | 2560×1350×2120 |

80T/3200 | 800 | 3200 | 2580 | 250 | 120 | 350 | 7.5 | 3260×1350×2120 |

80T/4000 | 800 | 4000 | 2980 | 250 | 120 | 350 | 7.5 | 4060×1350×2250 |

100T/2500 | 1000 | 2500 | 2000 | 300 | 130 | 400 | 7.5 | 2560×1465×2300 |

100T/3200 | 1000 | 3200 | 2580 | 300 | 130 | 400 | 7.5 | 3260×1465×2300 |

100T/4000 | 1000 | 4000 | 2980 | 300 | 130 | 400 | 7.5 | 4060×1465×2300 |

125T/2500 | 1250 | 2500 | 2000 | 300 | 130 | 400 | 11 | 2560×1465×2350 |

125T/3200 | 1250 | 3200 | 2580 | 300 | 130 | 400 | 11 | 3260×1465×2350 |

125T/4000 | 1250 | 4000 | 2980 | 300 | 130 | 400 | 11 | 4060×1465×2350 |

125T/4000 | 1250 | 4000 | 2980 | 300 | 130 | 400 | 11 | 4060×1465×2350 |

160T/3200 | 1600 | 3200 | 2580 | 340 | 150 | 450 | 11 | 3260×1620×2700 |

160T/4000 | 1600 | 4000 | 2980 | 340 | 150 | 450 | 11 | 4060×1620×2700 |

160T/5000 | 1600 | 5000 | 4000 | 340 | 150 | 450 | 11 | 5060×1620×2850 |

160T/6000 | 1600 | 6000 | 5000 | 340 | 150 | 450 | 11 | 6060×1620×3000 |

200T/3200 | 2000 | 3200 | 2580 | 340 | 150 | 450 | 15 | 3260×1620×2700 |

200T/4000 | 2000 | 4000 | 2980 | 340 | 150 | 450 | 15 | 4060×1620×2850 |

200T/5000 | 2000 | 5000 | 4000 | 340 | 150 | 450 | 15 | 5060×1620×2850 |

200T/6000 | 2000 | 6000 | 5000 | 340 | 150 | 450 | 15 | 6060×1620×3000 |

250T/3200 | 2500 | 3200 | 2580 | 400 | 200 | 500 | 18.5 | 3260×1700×2900 |

250T/4000 | 2500 | 4000 | 2980 | 400 | 200 | 500 | 18.5 | 4060×1700×2900 |

250T/5000 | 2500 | 5000 | 4000 | 400 | 200 | 500 | 18.5 | 5060×1700×3000 |

250T/6000 | 2500 | 6000 | 5000 | 400 | 200 | 500 | 18.5 | 6060×1800×3200 |

300T/3200 | 3000 | 3200 | 2580 | 400 | 200 | 520 | 22 | 3260×2000×3000 |

300T/4000 | 3000 | 4000 | 2980 | 400 | 200 | 520 | 22 | 4060×2000×3000 |

300T/5000 | 3000 | 5000 | 4000 | 400 | 200 | 520 | 22 | 5060×2000×3200 |

|

300T/6000

|

3000 | 6000 |

5000

|

400 | 200 | 520 | 22 |

6060×2100×3400

|

350T/3200 | 3500 | 3200 | 2580 | 400 | 250 | 570 | 22 | 3260×2000×3000 |

350T/4000 | 3000 | 4000 | 2980 | 400 | 250 | 570 | 22 | 4060×2000×3000 |

350T/5000 | 3000 | 5000 | 4000 | 400 | 250 | 570 | 22 | 5060×2000×3200 |

350T/6000 | 3000 | 6000 | 5000 | 400 | 250 | 570 | 22 | 6060×2100×3400 |

400T/3200 | 4000 | 3200 | 2580 | 400 | 250 | 580 | 22 | 3260×2000×3100 |

|

400T/4000

|

4000 | 4000 |

2980

|

400 | 250 | 580 | 22 |

4060x2100x2900

|

400T/5000 | 4000 | 5000 | 4000 | 400 | 250 | 580 | 22 | 5060×2000×3300 |

500T/4000 | 5000 | 4000 | 2980 | 500 | 300 | 640 | 37 | 4100×2300×3600 |

500T/5000 | 5000 | 5000 | 4000 | 500 | 300 | 640 | 37 | 5100×2450×4000 |

500T/6000 | 5000 | 6000 | 5000 | 500 | 300 | 640 | 37 | 6100×2450×4200 |

600T/4000 | 6000 | 4000 | 2980 | 500 | 300 | 660 | 45 | 4100×2300×3600 |

600T/5000 | 6000 | 5000 | 4000 | 500 | 300 | 660 | 45 | 5100×2450×4000 |

600T/6000 | 6000 | 6000 | 5000 | 500 | 300 | 660 | 45 | 6100×2450×4200 |

WD67Y press brake Machine Details Display

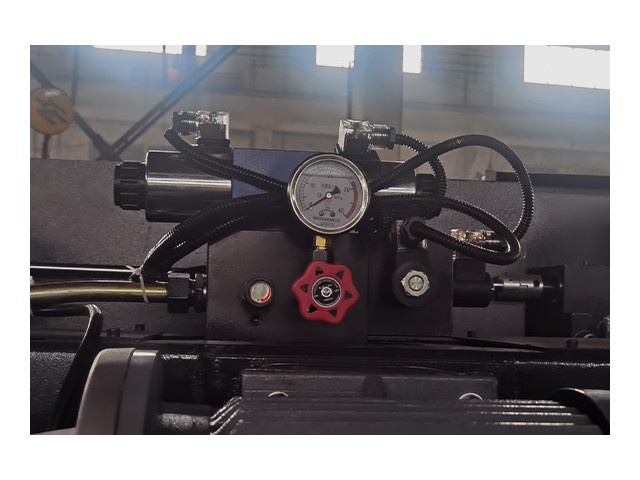

Hydraulic valve group

Main Motor

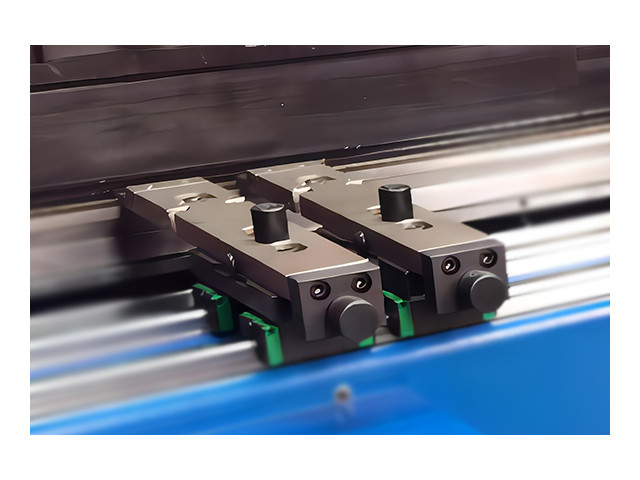

Stop finger

Fast Clamp

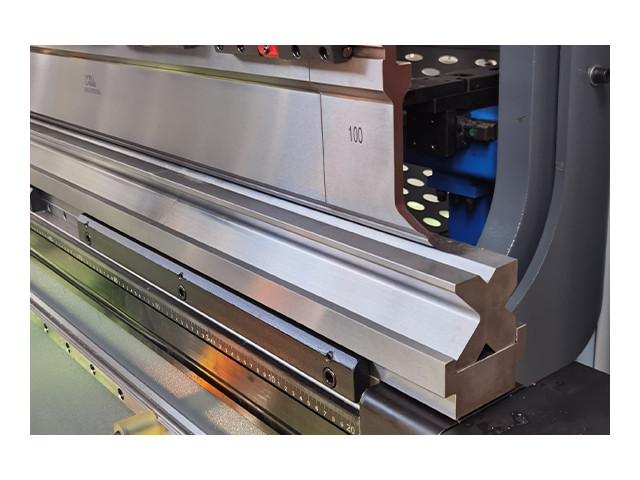

Press brake tooling

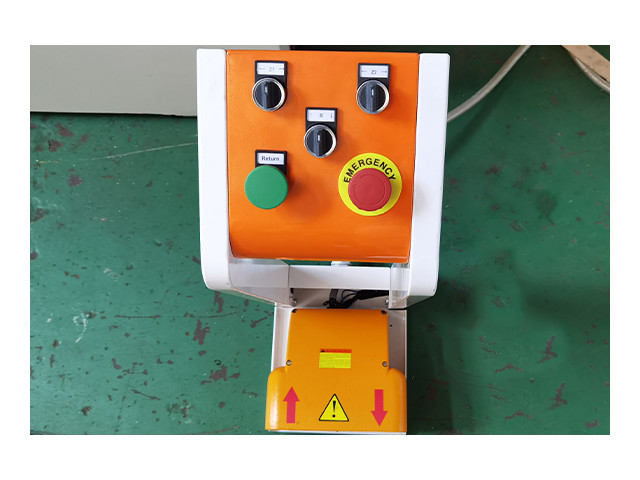

Foot switch

Front Support

Grating Ruler

WD67Y press brake Machine FAQ

What is the WD67Y press brake?

WD67Y is a hydraulic press brake designed for precise and efficient sheet metal bending. It features NC (numerical control) technology to simplify operation and increase productivity.

What materials can WD67Y process?

The machine is suitable for bending a variety of materials including carbon steel, stainless steel, aluminum and other sheet metals.

What are the main advantages of the WD67Y series?

Cost-effective sheet metal bending solutions.

Reliable hydraulic system ensures consistent performance.

User-friendly controls with CNC programming for simple operation.

Rugged construction for durability and precision.

What is the difference between NC and CNC in bending machines?

NC (numerical control) systems, such as the one in the WD67Y, offer simpler programming and manual adjustments and are ideal for less complex tasks. CNC (computer numerical control) systems are fully automatic and have more advanced programming capabilities, ideal for complex designs and high-precision projects.

Which industries commonly use WD67Y bending machines?

It is widely used in industries such as automotive manufacturing, construction, HVAC, and custom metal fabrication.