WF67K-C Electro-Hydraulic Servo CNC Press Brake | Efficient and Accurate

- Price

- US $8000-6000

- Model

- WF67K-C 110T2500

- MOQ

- 1 piece

Item specifics

- color

- Blue and white

- Machine Type

- Synchronized

- Degree of automation

- Fully Automatic

- Degree of oldness

- New

- country of origin

- China

- Machinable materials

- Brass/ Copper, Stainless steel, Carbon steel

- Core selling point

- High-accuracy

- Warranty

- 3 years

- Applicable industries

- Hotels, Machinery Repair Shops

- Marketing Type

- New Product 2024

- Mechanical test report

- Provided

- Video factory inspection

- Provided

- Core component warranty period

- 1 Year

Review

Description

WF67K-C Electro-Hydraulic Servo CNC Press Brake Introduction

WF67K-C Series Electro-Hydraulic Servo CNC Press Brake: Energy-Saving, High Precision, and Efficient Performance

Large CNC hydraulic press brake WF67K-C fully automatic electro-hydraulic servo press brake has an electro-hydraulic servo system that adopts an on-demand oil supply method to reduce overflow and save more than 30% of energy. Its advantages are long oil change intervals, reducing energy waste and reducing costs. User cost, when bending workpieces of different specifications, the speed is adjustable, high precision, energy saving,environmentally friendly and efficient.

WF67K-C Electro-Hydraulic Servo CNC Press Brake Application Scenario

WF67K-C Electro-Hydraulic Servo CNC Press Brake Advantages

Feature 1

Independent tank

Over 85% of the faults of the bending machine are related to the cleanliness of the hydraulic oil passage. Our company is equipped with an independent tank with special processing technology,which can reduce the faults related to hydraulic oil to the greatest extent,ensure the stable operation of the machine tool and reduce the failure rate of the equipment,Electric cabinet Grating ruler.

Feature 2

The single servo press brake is energy-efficient, precise, and low-maintenance, suitable for high-precision, light to medium-duty tasks. The electric hydraulic press brake, on the other hand, provides higher power for heavy-duty applications but is less energy-efficient and requires more maintenance due to its hydraulic components.

WF67K-C One-way Servo Pump CNC Press Brake Machine Technical Parameters

WF67K-C press brake series offers a variety of models, covering a variety of needs from small to large, the specific technical parameters range as follows:

Model

WF67K-series | Nominal

Pressure

(mm) | Bending

Length

(mm) | Poles

distance

(mm) | Throat

depth

(mm) | SlipperStroke(mm) | Max

Opening

Height

(mm) | Main

motor

(KW) | Travel

(mm) | Weight

(Kg) |

40T/1600 | 400 | 1600 | 1260 | 300 | 150 | 420 | 5.5 | 500 | 3800 |

63T/2500 | 630 | 2500 | 2000 | 300 | 150 | 420 | 5.5 | 500 | 4800 |

80T/2500 | 800 | 2500 | 2000 | 350 | 200 | 480 | 7.5 | 600 | 5700 |

|

100T/3200

|

1000

|

3200

|

2700 | 400 |

200/250

|

480/520 | 7.5 | 600 | 8500 |

|

100T/4000

|

1000

|

4000

|

3600 | 400 |

200/250

|

480/520 | 7.5 | 600 | 9300 |

|

160T/3200

|

1600

|

3200

|

2700 | 400 |

200/250

|

480/520 | 11 | 600 | 9500 |

160T/4000 | 1600 | 4000 | 3600 | 400 | 200/250 | 480/520 | 11 | 600 | 12100 |

|

200T/3200

|

2000

|

3200

|

2700 | 400 |

250

|

530 | 15 | 600 | 11000 |

200T/4000 | 2000 | 4000 | 3600 | 400 | 250 | 530 | 15 | 600 | 13500 |

250T/3200 | 2500 | 3200 | 2700 | 400 | 250 | 530 | 18.5 | 600 | 13000 |

250T/4000 | 2500 | 4000 | 3600 | 400 | 250 | 530 | 18.5 | 600 | 15500 |

250T/5000 | 2500 | 5000 | 4300 | 400 | 250 | 530 | 22 | 600 | 18000 |

300T/3200 | 3000 | 3200 | 2700 | 400 | 300 | 580 | 22 | 600 | 19200 |

300T/4000 | 3000 | 4000 | 3600 | 400 | 300 | 580 | 22 | 600 | 22500 |

400T/4000 | 4000 | 4000 | 3600 | 400 | 320 | 580 | 30 | 600 | 25500 |

400T/5000 | 4000 | 5000 | 4000 | 400 | 320 | 580 | 30 | 600 | 31500 |

500T/4000 | 5000 | 4000 | 3500 | 500 | 320 | 590 | 37 | 600 | 34500 |

500T/5000 | 5000 | 5000 | 4000 | 500 | 320 | 590 | 37 | 800 | 43500 |

500T/6000 | 5000 | 6000 | 5000 | 500 | 320 | 590 | 37 | 800 | 53000 |

600T/5000 | 6000 | 5000 | 4000 | 500 | 320 | 640 | 45 | 800 | 57000 |

600T/6000 | 6000 | 6000 | 5000 | 500 | 320 | 640 | 45 | 800 | 68000 |

600T/7000 | 6000 | 7000 | 6000 | 500 | 320 | 640 | 45 | 800 | 79000 |

800T/6000 | 8000 | 6000 | 5000 | 600 | 400 | 800 | 55 | 800 | 90000 |

800T/7000 | 8000 | 7000 | 6000 | 600 | 400 | 800 | 55 | 800 | 105000 |

800T/8000 | 8000 | 8000 | 7000 | 600 | 400 | 800 | 55 | 800 | 120000 |

1000T/6000 | 10000 | 6000 | 5000 | 600 | 400 | 800 | 2x37 | 800 | 100000 |

1000T/8000 | 10000 | 8000 | 6900 | 700 | 400 | 800 | 2x37 | 800 | 130000 |

1000T/10000 | 10000 | 10000 | 8000 | 700 | 400 | 800 | 2x37 | 800 | 150000 |

1200T/6000 | 12000 | 6000 | 4220 | 700 | 400 | 1000 | 2x45 | 1000 | 130000 |

1200T/7000 | 12000 | 7000 | 5220 | 700 | 400 | 1000 | 2x45 | 1000 | 160000 |

1600T/6000 | 16000 | 6000 | 4900 | 700 | 400 | 1000 | 2x55 | 1000 | 150000 |

1600T/7000 | 16000 | 7000 | 5900 | 700 | 400 | 1000 | 2x55 | 1000 | 170000 |

1600T/8000 | 16000 | 8000 | 6900 | 700 | 400 | 1000 | 2x55 | 1000 | 190000 |

1600T/10000 | 16000 | 10000 | 8000 | 700 | 400 | 1000 | 2x55 | 1000 | 210000 |

2000T/8000 | 20000 | 8000 | 6200 | 700 | 400 | 1000 | 2x55 | 1000 | 260000 |

2000T/10000 | 20000 | 10000 | 8000 | 700 | 400 | 1000 | 2x55 | 1000 | 290000 |

2000T/12000 | 20000 | 12000 | 9050 | 700 | 400 | 1000 | 2x55 | 1000 | 320000 |

2000T/14000 | 20000 | 14000 | 11000 | 700 | 400 | 1000 | 2x55 | 1000 | 350000 |

3000T/8000 | 30000 | 8000 | 6200 | 700 | 400 | 1000 | 2x55 | 1000 | / |

3000T/10000 | 30000 | 10000 | 8000 | 700 | 400 | 1000 | 2x55 | 1000 | / |

3000T/12000 | 30000 | 12000 | 9050 | 700 | 400 | 1000 | 2x55 | 1000 | / |

3000T/14000 | 30000 | 14000 | 11000 | 700 | 400 | 1000 | 2x55 | 1000 | / |

Parameters within this range reflect the wide applicability of the WF67K-C series press brakes in different application scenarios, from small and medium-sized precision processing to large-scale industrial manufacturing.

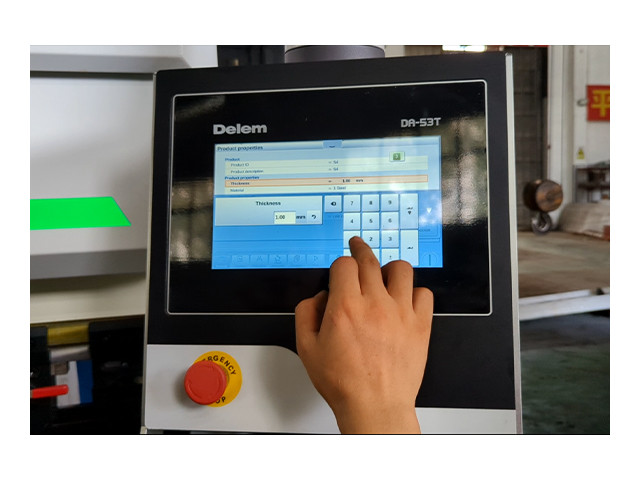

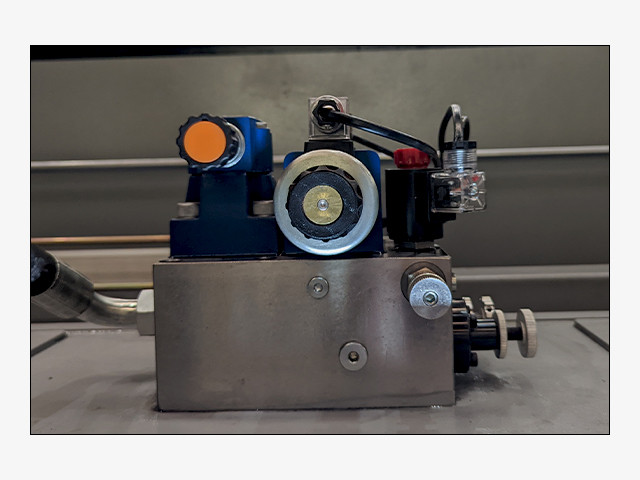

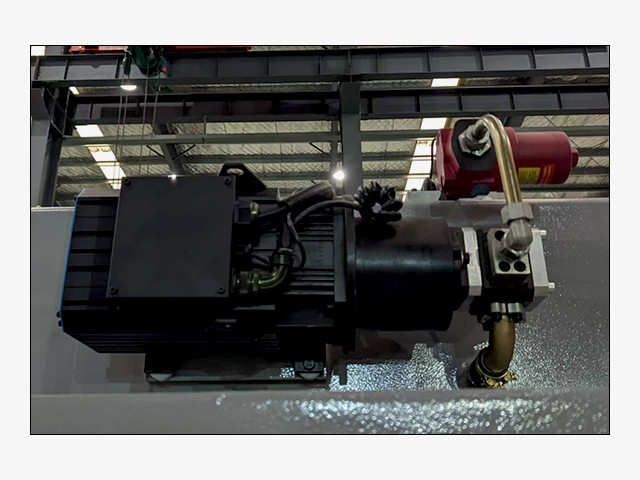

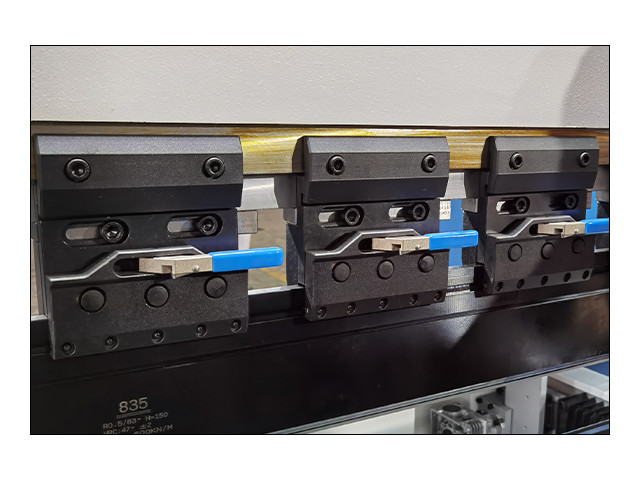

WF67K-C One-way Servo Pump CNC Press Brake Machine Details Display

Hydraulic valve group

Main motor

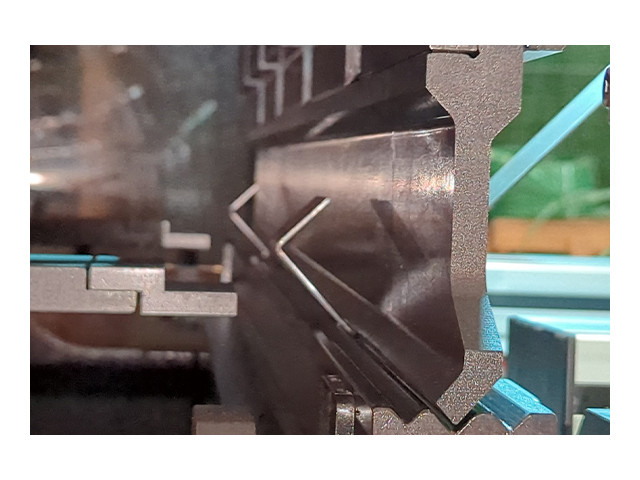

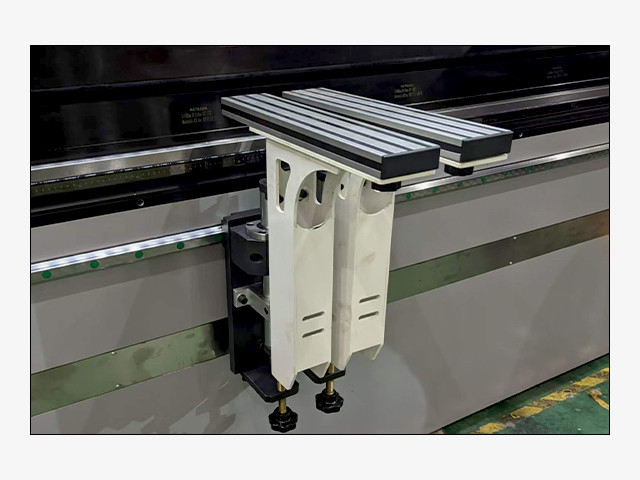

Stop finger

Fast clamp

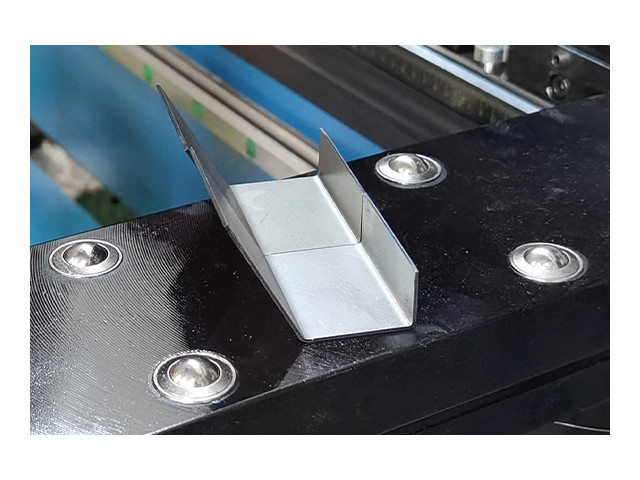

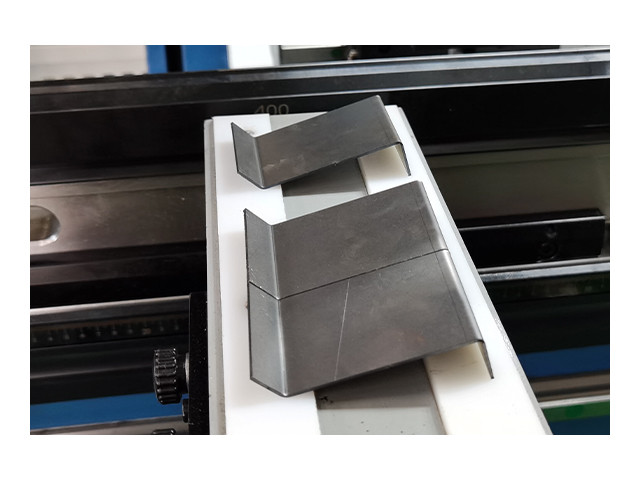

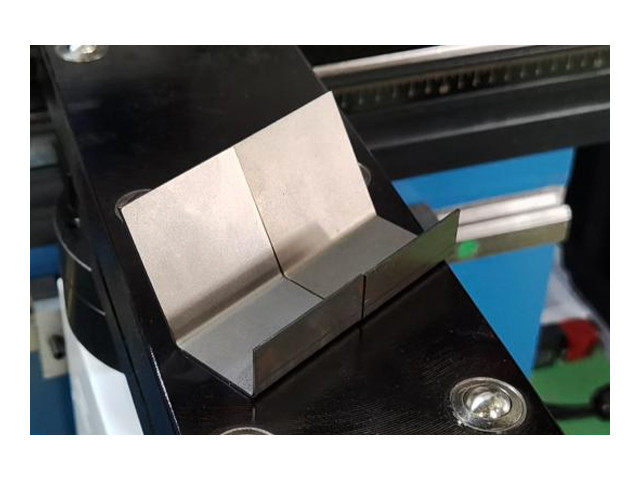

Press brake tooling

Foot switch

Front support

Back gauge

WF67K-C One-way Servo pump CNC press brake Machine FAQ

What is the primary advantage of the One-Way Servo Pump in the WF67K-C Press Brake?

The One-Way Servo Pump provides significant energy savings compared to traditional hydraulic systems by only using power when needed, which improves efficiency and reduces operating costs.

What materials can the WF67K-C CNC press brake handle?

The WF67K-C is capable of bending a variety of metals, including stainless steel, carbon steel, aluminum, and other sheet metals, making it suitable for a wide range of applications in industries such as automotive, construction, and metal fabrication.

How accurate is the bending process?

The WF67K-C offers high precision bending with advanced CNC controls, ensuring consistent results for complex bends and tight tolerances.

What are the benefits of the CNC control system?

The CNC system allows for easy programming and setup, providing flexibility for a wide range of bending tasks. It also ensures accuracy and repeatability, reducing setup time and human error.