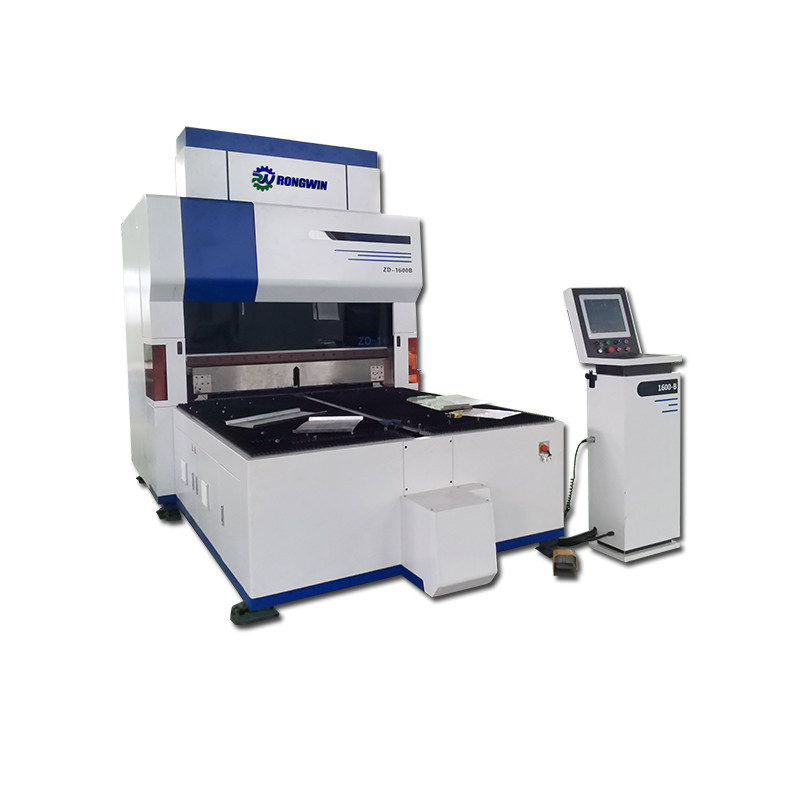

RONGWIN Customizable Panel Bender | Sheet Metal Forming

- Price

- US $6000-4800

- Model

- Panel Bender

- MOQ

- 1 piece

Item specifics

- Machine type

- panel bender

- Degree of automation

- Fully Automatic

- Degree of oldness

- New

- Country of origin

- China

- Machinable materials

- Brass/Copper/Stainless Steel

- Core selling point

- Automatic

- Warranty

- 1 Year

- Marketing type

- New Product 2024

- Mechanical test report

- Provided

- Core component warranty period

- 1 Year

Review

Description

Panel Bender Introduction

RONGWIN Servo-Controlled Panel Bender for High-Precision Metal Sheet Bending

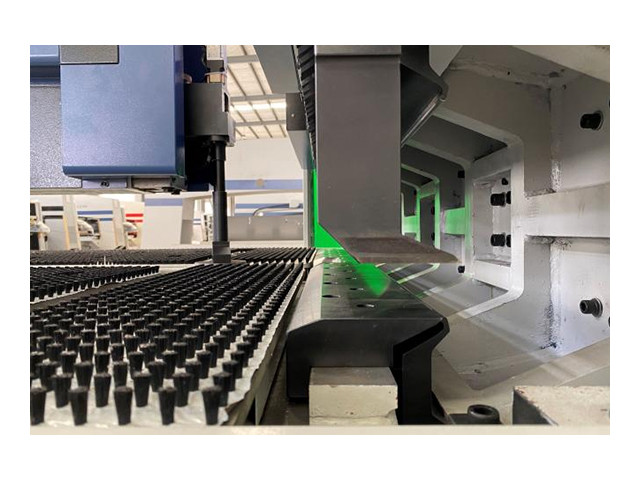

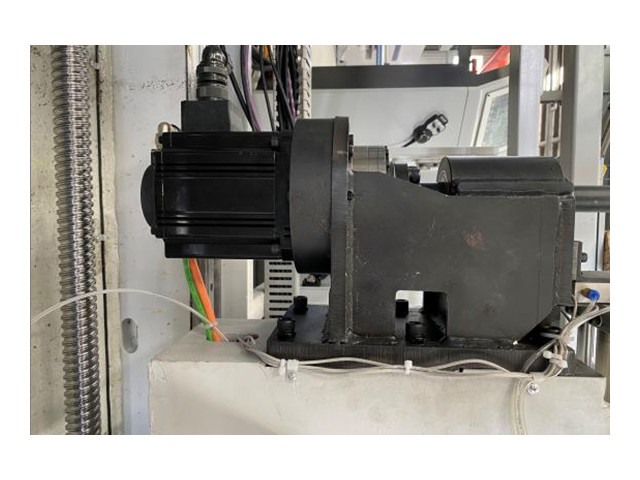

Rongwin panel bender adopts a full servo system. Unlike traditional bending machines, the bending machine mold needs to be pressed down against the fixed part of the bending machine, but the bending work is completed by the blade. During the bending process, the plate The material holder fixes the plate. The blade can bend up or down in different shapes. First, one side is bent outward, and then it is automatically bent inward. These different actions are controlled by the servo electric transmission device, which can ensure the highest positioning accuracy in the bending sequence and bring the best bending effect.

Panel Bender Application Scenario

Panel Bender Advantages

Feature 1

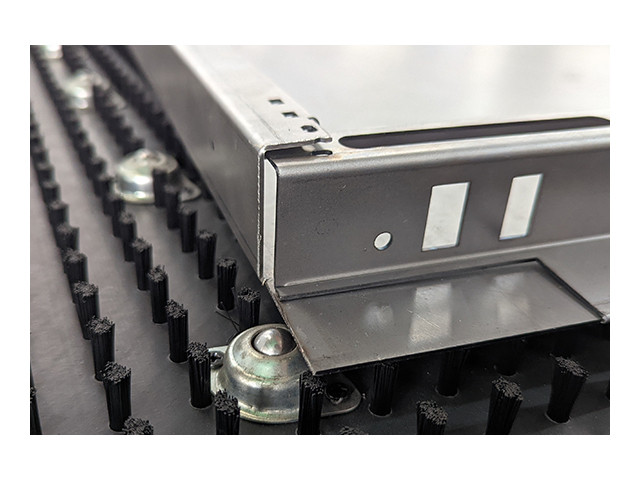

Positioning pushing device

will place the plate to be folded inthe X and Y directions, which canrealize the pre-positioning betweenthe plate and the machine tool.There are two groups of positioningblocks, which can locate the cornerand the edge respectively. Thecombination has nine positioningfunctions, and the Y direction of theleft and right positioning seat canbe adjusted (+50mm) to adapt tothe positioning funetion of varioussheets.

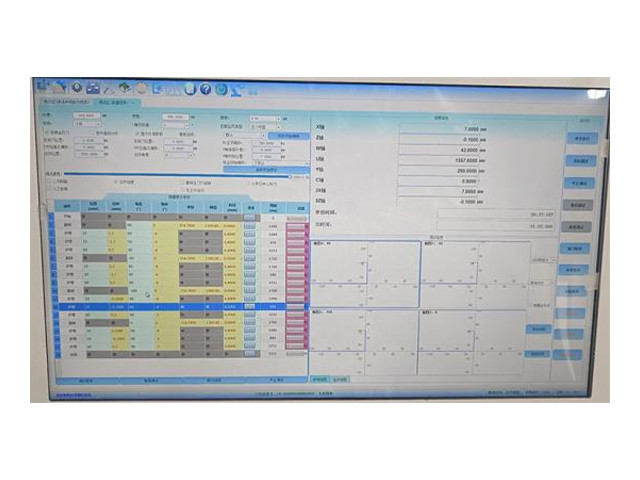

Feature 2

Smart Control system

Rongwin's brand-new selfdeveloped full-servo CNC systemhas seamless and coherentmovements, leading the world inwork efficiency, andindependently designed hardwarecircuit boards with lead-freesoldering and surface immersiongold processing technology.which is stable and durable.Abundant interfaces are reservedto support CNC, PLC, robot, etc.Provide partners with free lifetimesystem upgrade services.

Panel Bender Technical Parameters

Panel Bender offers a variety of models, covering a variety of needs from small to large, the specific technical parameters range as follows:

Items | RWAO21000X | RWAO2 1400X | RWAO21000XC | RWAO2.1400XC | RWAOS1400PC1PC3 | RWAOS.2000PC1/C3 | RWAOS.2500PC1PC3 | RWAOS.2000PS | RWAOS2500PS | RWAOS3200PS | RWAOS2000A | RWAOS.2500A | |

Axis QTY | 9 | 9 | 11 | 11 | 15 | 15 | 15 | 18 | 18 | 18 | 21 | 21 | |

Max,bending width of sheet metal | 1000mm | 1400mm | 1000m | 1400mm | 1400mm | 2000mm | 2500mm | 2000mm | 2500mm | 3200mm | 2000mm | 2500mm | |

Max.bending height(afer bending) | 170mm | 170mm | 170mm | 170mm | 170mm300mm(PC3) | 1 70mm300mm(PC3) | 1 70mm300mm(PC3) | 1 70mm | 170mm | 170mm | 170mm | 170mm | |

Max.bending thickness of sheet metal | Material:st37 black materia | 1.0mm | 1.0mm | 1.0mm | 1.0mm | 1.20mm | 1.2mm | 1.2nm | 2.0mm | 2.0mm | 1.5mm | 1.5mm | 1.5mm |

Material:AISI 304 Stainless steel | 1.2mm | 1.2mm | 1.2mm | 1.2mm | 1.5mm | 1.5mm | 1.5mm | 3.0mm | 3.0mm | 2.0mm | 2.0mm |

2.0mm

|

|

Material;UsT 265N/mm2 aluusninu | 1.6mm | 1.6mm | 1.60mm | 1.6mm | 2.0mm | 2.0mm | 2.0mm | ------- | -------- | ------- | 3.0mm | 3.0mm | |

Min-panel thickness ofsheet metal | 0.35mm | 0.35mm | 0.35mm | 0.35mm | 0.35mm | 0.35mm | 0.35mm | 0.35mm | 0.35mm | 0.35mmn | 0.35mm | 0.35mm | |

Max.bending size ofsheet anetal | 1000*1000mm | 1400*1400mm | 1000*1000

mm | 1400*1400

mm | 1400*1400mm | 2000*1500

mm | 2500*1500mm | 2000*1500

mm | 2500*1500

mm | 3200*1500

mm | 2000*1500

mm | 2500*1500mm | |

|

Feeding Mfethod

|

Suetion cup Used on sanooth pinel surice,no punching,noholes,which benefits suction cup to adsorb. | Pressing armit is suitable for mesh,corgated,hollow andwarious flnt or special-shaped work pieces |

|||||||||||

Parameters within this range reflect the wide applicability of the Panel Bender Press Brake in different application scenarios, from small and medium-sized precision processing to large-scale industrial manufacturing.

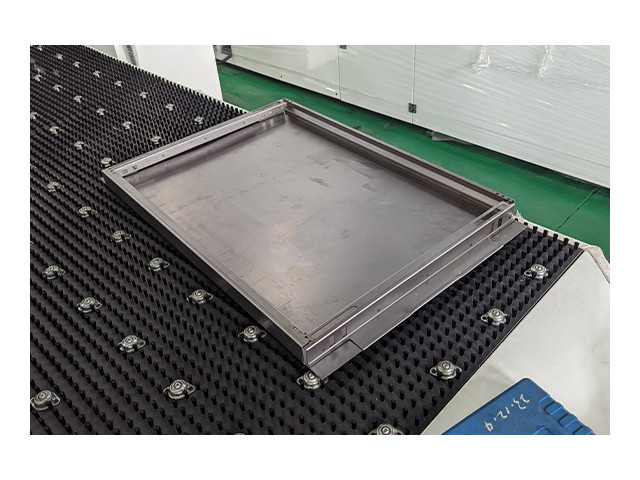

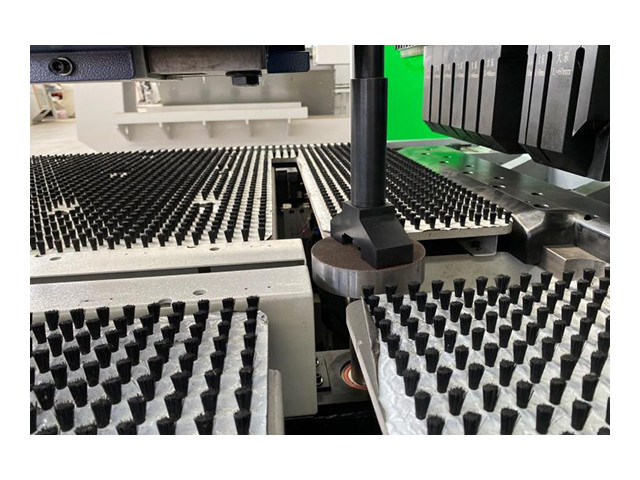

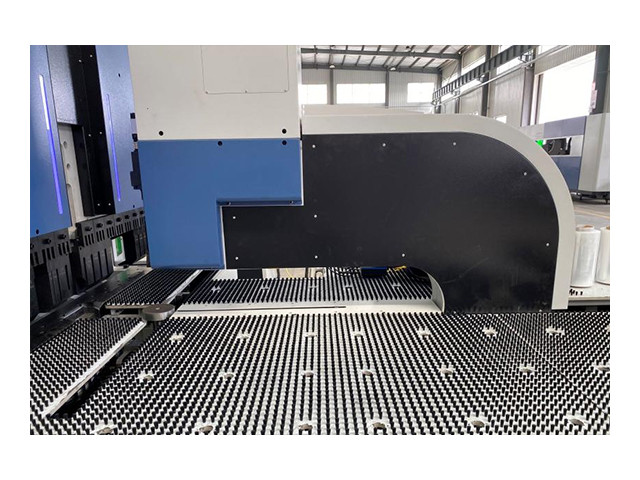

Panel Bender Details Display

Rotating device

Press tooling

High strength frame

The servo drive motor

Panel Bender FAQ

Can you supply the relevant documentation?

Yes, we can provide most documentation including Certificates of Analysis / Conformance; Insurance; Origin, and other export documents where required.

What is the average lead time?

For samples, the lead time is about 7 days. For mass production, the lead time is 20-30 days after receiving the deposit payment.

The lead times become effective when (1) we have received your deposit, and (2) we have your final approval for your products. If our lead times do not work with your deadline, please go over your requirements with your sale. In all cases we will try to accommodate your needs. In most cases we are able to do so.

What kinds of payment methods do you accept?

You can make the payment to our bank account, Western Union or PayPal:30% deposit in advance, 70% balance against the copy of B/L.

What is the product warranty?

We warranty our materials and workmanship. Our commitment is to your satisfaction with our products. In warranty or not, it is the culture of our company to address and resolve all customer issues to everyone’s satisfaction.