RONGWIN Panel Bender Full Automatic Bending | Press arm type | Precision Technology

- Price

- US $40000-36000

- Model

- RWA03-1000P

- MOQ

- 1 piece

Item specifics

- Machine Type

- Synchronized

- Length of Working Table (mm)

- 3200

- Motor Power (kw)

- 11 kw

- Material

- Metal Steel Sheet

- Control System

- Touch Screen

- Video Outgoing-Inspection

- Provided

- Machinery Test Report

- Provided

- CNC or not

- CNC Bending Machine

Review

Description

Why Choose Our Panel Bender? Key Features & Competitive Advantages

Pain Points

Traditional bending equipment has low efficiency

High mold cost

Complex operation

Unstable precision

Poor material compatibility

Selling Points

Efficient intelligent bending unit

One machine for multiple molds

High-precision automation

Supports multi-material processing

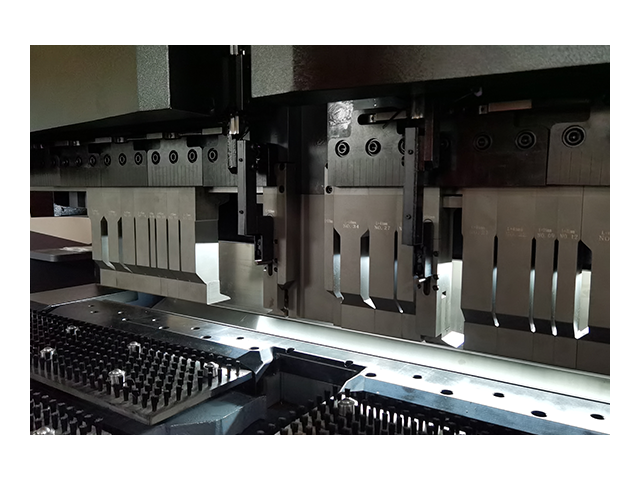

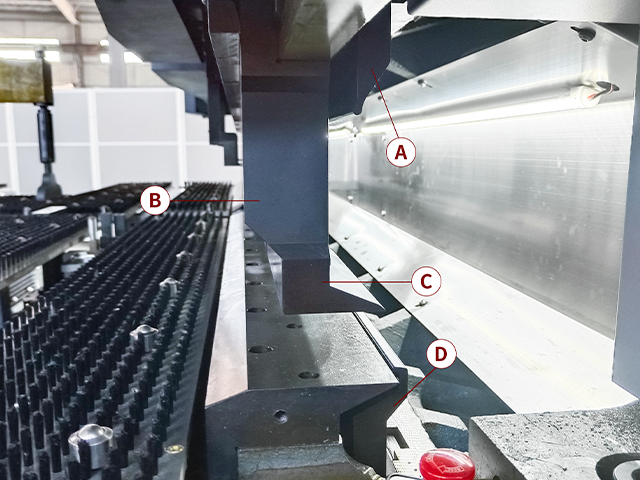

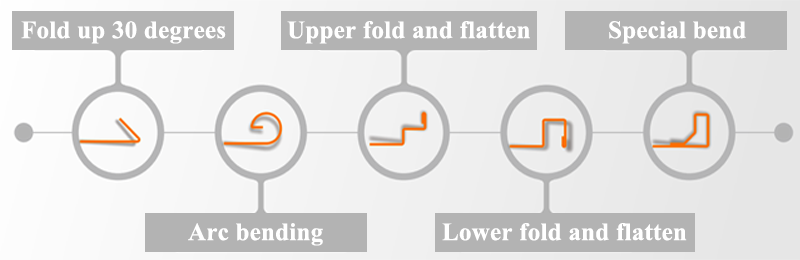

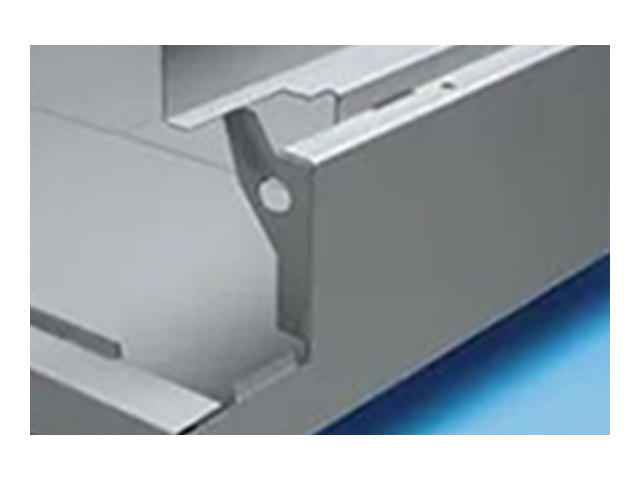

Advantage 1 | Universal mold design

No need for frequent mold changes

Universal mold design, one machine can complete bending of multiple shapes (such as arc, closed type, etc.)

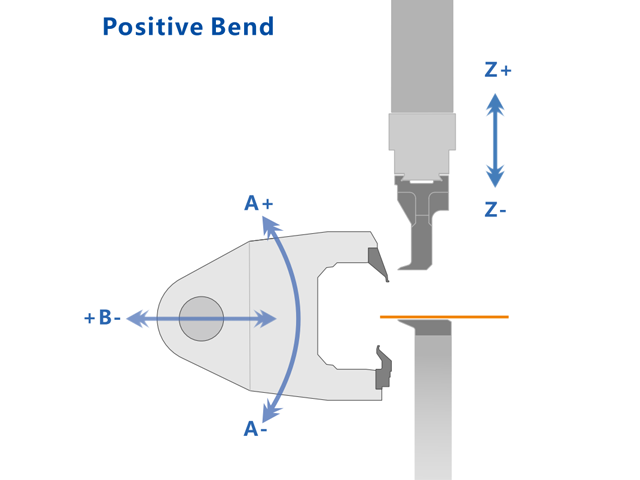

The upper bending to(A) is the same bending mold, which can bend

(B)Work at the same time accurately and efficiently fix and fold dome

The lower table (C)clamps the plate when folding the dome

The lower bending knife(D)is a general bending die, which can bend upwards

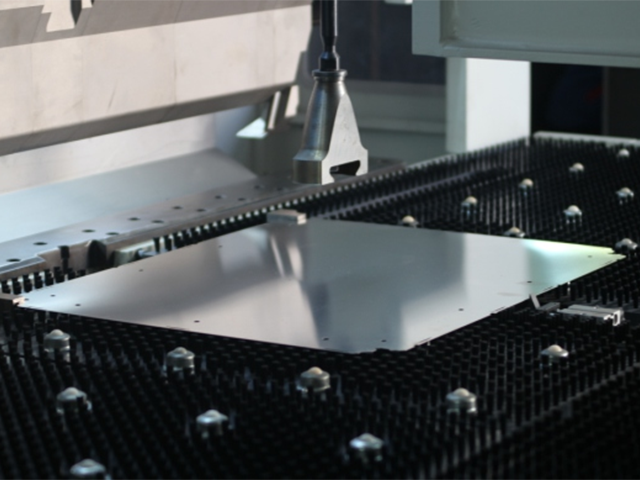

Advantage 2 | Efficient bending

High efficiency production

0.2 seconds/time ultra-fast bending speed

Integrated robot for automatic loading and unloading

Supports 24-hour continuous operation

Advantage 3 | Flexible adaptation

Multi-material compatibility

Stainless steel, aluminum plate, cold-rolled plate (0.35-3mm thickness full coverage)

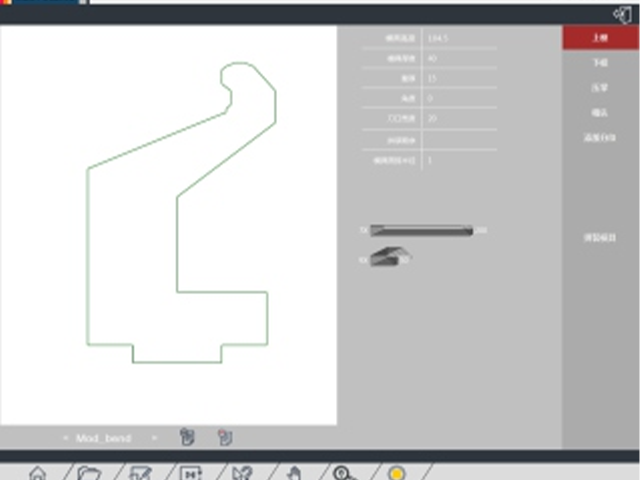

Advantage 4 | Intelligent automation

Intelligent operation

Touch-click programming, user-friendly.

Real-time WYSIWYG display.

Supports

complex processes in one step.

Handwheel

simulation prevents interference.

3D STEP

import for direct processing.

DELEM-LINUX

system for instant shutdown.

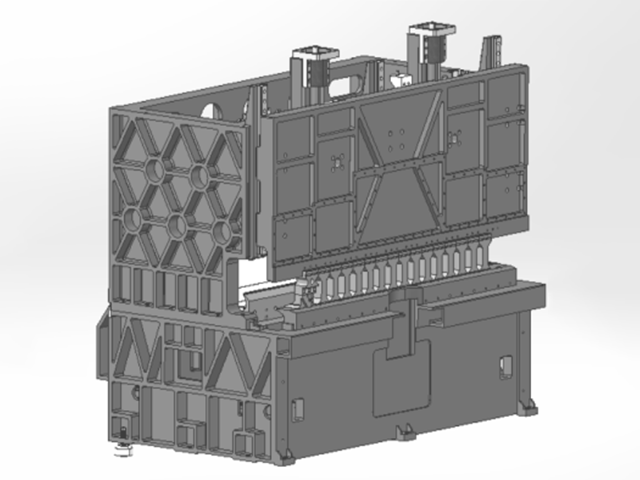

Advantage 5 | Body structure comparison

Features of split cast iron frame

The strength and rigidity of the cast iron frame are relatively low, but the internal friction is large and the damping effect is large, so the vibration resistance is good, which has obvious advantages for machine tools with high static requirements.

Reasonable casting shape and pouring are key factors to ensure the performance of castings

Features of integral welded frame

The strength of the welded frame structure is 2.5 times that of cast iron, and the steel frame is 3 times that of cast iron, but the vibration resistance is relatively poor, and the static deformation resistance is relatively poor.

After welding, the welding process sequence is aging treated by natural or annealing processes. The welding process sequence has a great influence on the performance of the overall frame, and the technical level of the welding technician is very high.

New structure welding frame

This frame has all the characteristics of a welded frame, with good rigidity and high strength. It has been aged by heat treatment to make the frame more stable. This model has changed the mechanical structure, and the key moving parts are connected by articulated shafts, which has higher precision and more efficient movement.

Panel Bender Technical Specifications: Find the Perfect Model for Your Needs

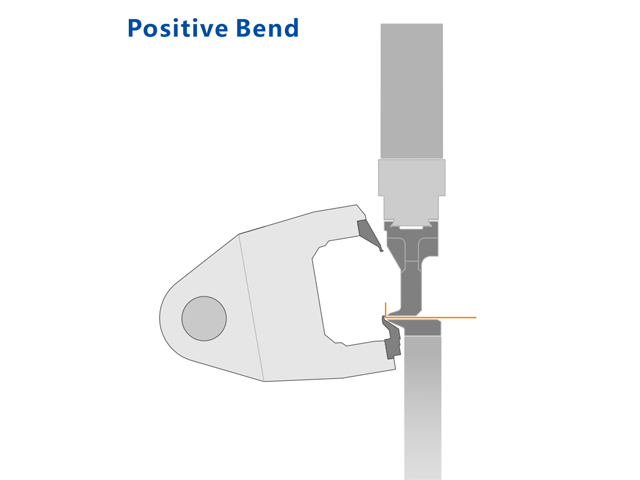

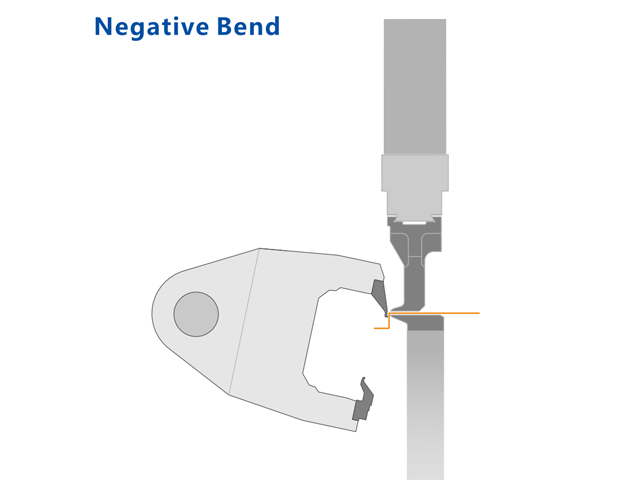

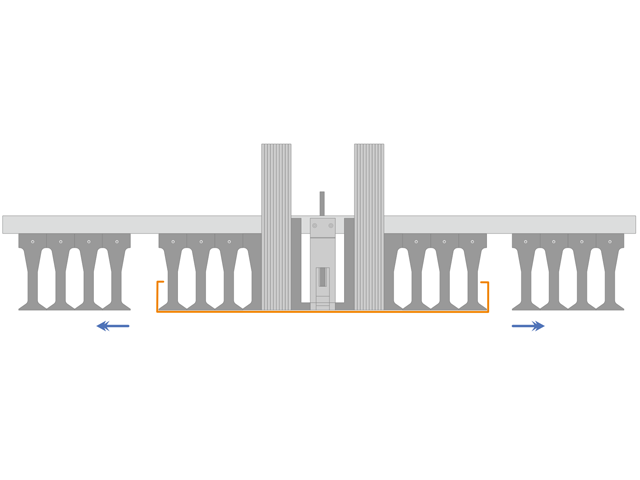

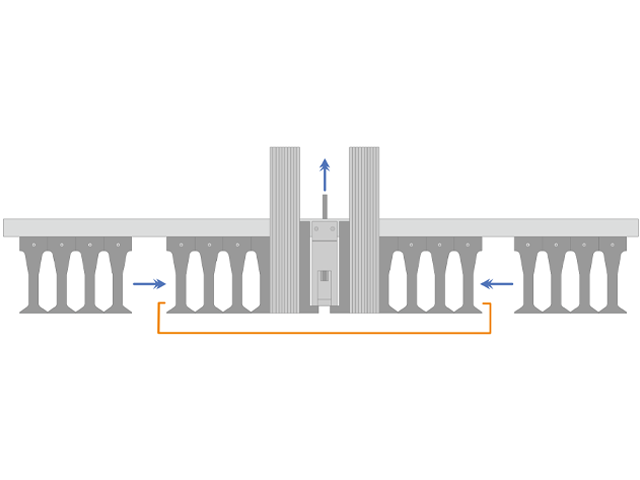

Bending principle and action diagram

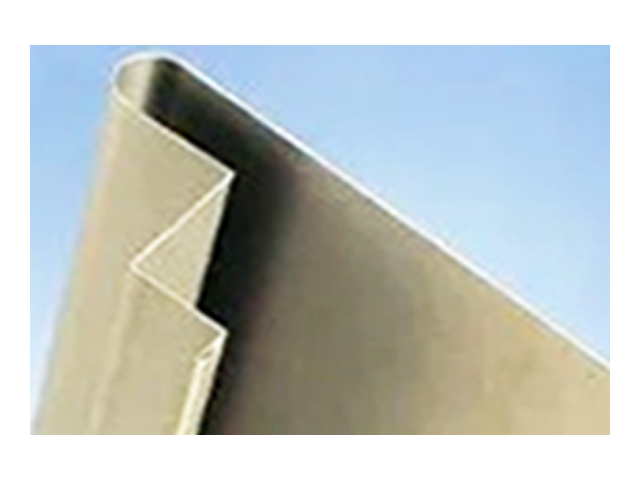

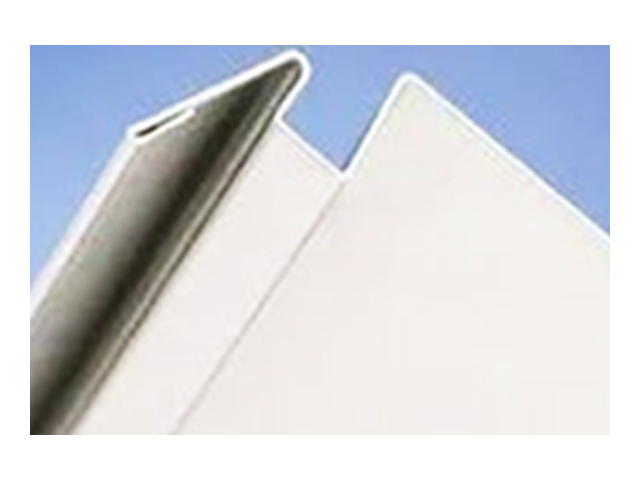

Positive Bend

Positive Bend

Negative Bend

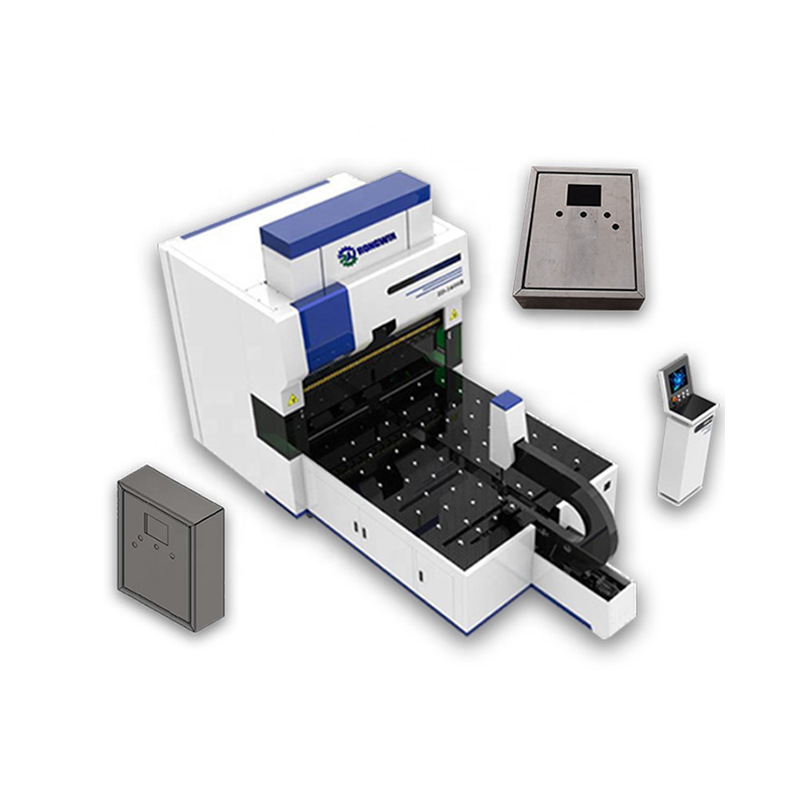

Suction cup universal series

Suction cup universal series flexible panel bender

Suction cup feeding, compact structureMachine features

Adopts suction cup feeding method

Suitable for workpieces with flat surface that can be sucked by suction cups. Standard 11-axis concurrent linkage control, standard power hinge knife, small footprint, convenient loading and unloading

Model:

RWA02-1000X

RWA02-1400X

| Name | RWA02-1000X | RWA02-1400X |

| Maximum bending size(Length X Width) | 1000mmX1000mm | 1400mmX1250mm |

Maximum bending height | 170mm | |

Minimum arc radius | 2mm (depending on the thickness of the plate) | |

Dimensions(mm) | 3000*2200*2200 | 3800*2550*2400 |

Maximum bending thickness | 304 stainless steel 1.0mm | |

Carbon steel plate 1.2mm | ||

Aluminum plate 2.5mm | ||

Number of axes | Customized | |

Suction cup feeding method

The machine has a compact structure, with more space for placing materials, and it is relatively more convenient to put materials in and take materials out.

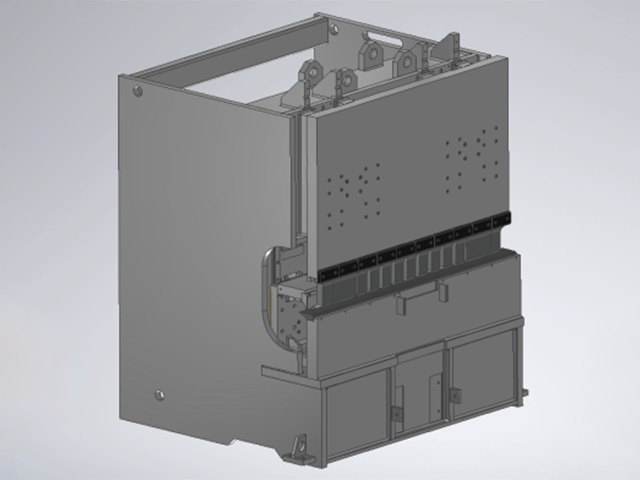

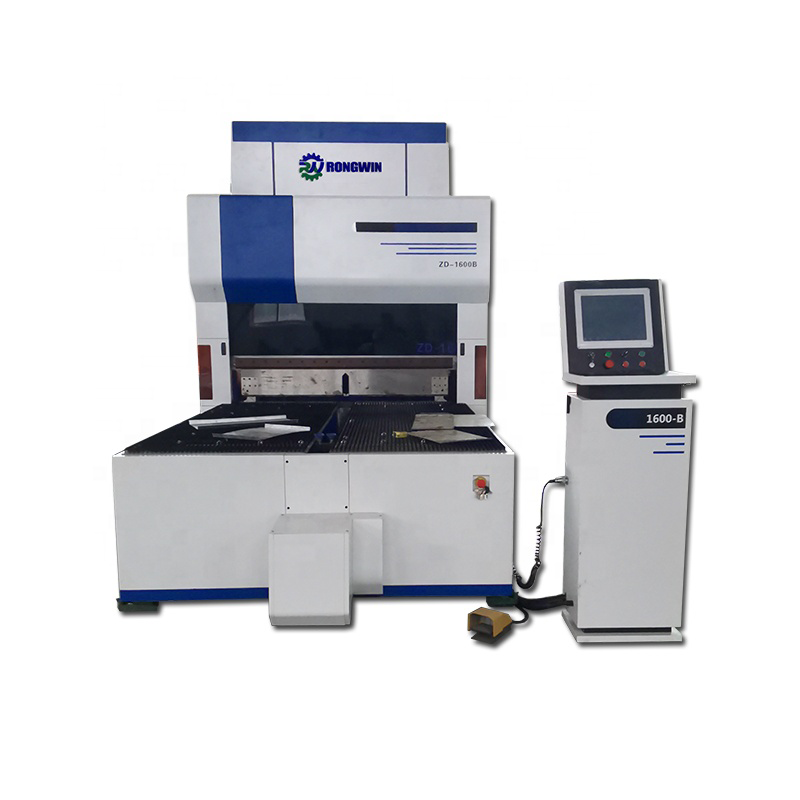

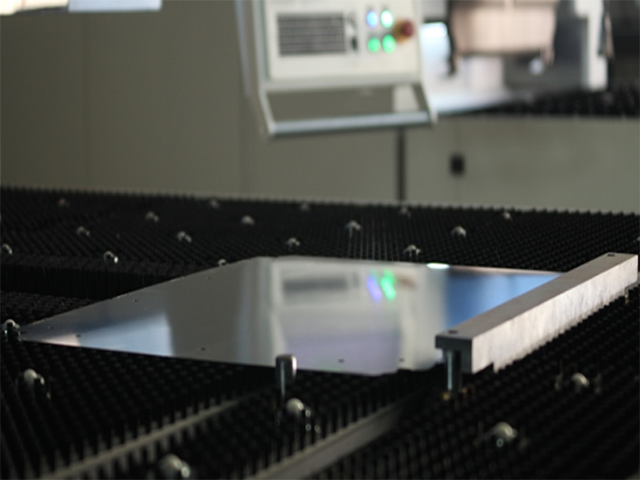

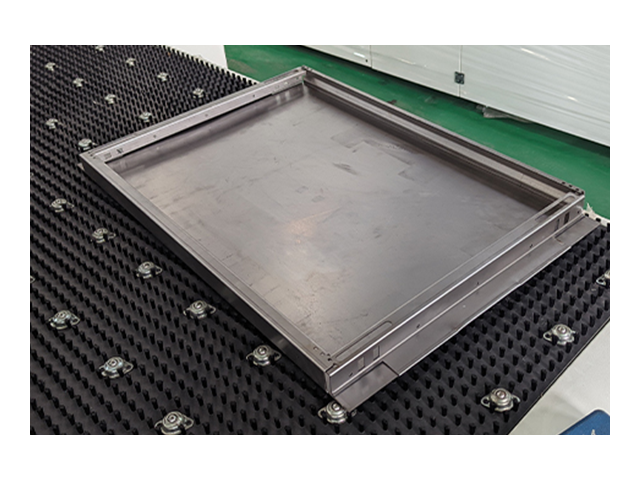

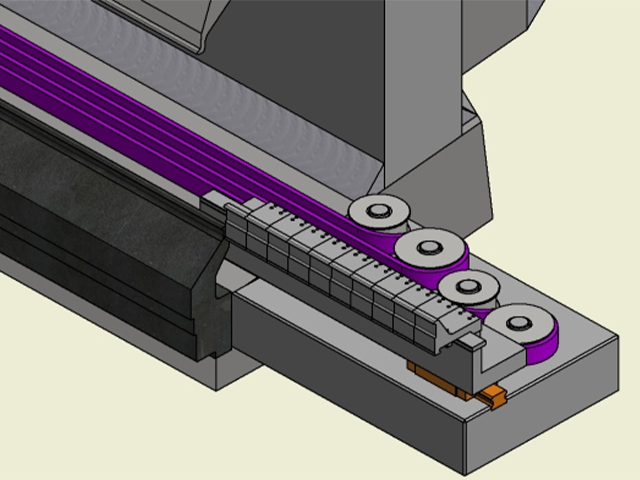

Pressure arm universal series

Pressure arm universal series flexible panel bender

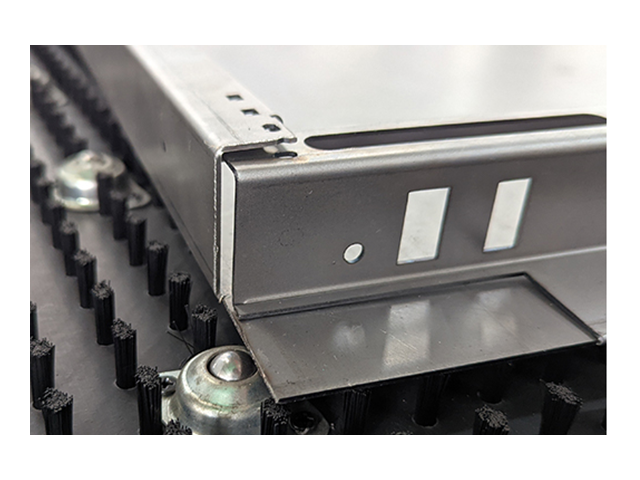

Press-arm feeding, strong versatilityFeatures of the machine

Adopts the press-arm feeding method

Mesh, corrugated, hollow and various flat or special-shaped workpieces are suitable for standard power hinge knives to avoid scraping and scratching

Various knife hanging methods are optional

Model:

RWA03-1000P / RWA03-1400P / RWA03-2000P / RWA03-2500P

| Name | RWA03-1000P | RWA03-1400P | RWA03-2000P | RWA03-2500P |

| Maximum bending size(Length X Width) | 1000mmX1000mm | 1400mmX1250mm | 2000mmX1250mm | 2500mmX1250mm |

Maximum bending height | 170mm | "170mm/240mm 280mm (opposite side)" | ||

Minimum arc radius | 2mm (depending on the thickness of the plate) | |||

Dimensions(mm) | 4000*2200*2200 | "4600*2600*2400 | "5150*3200*2300 | "6100*3800*2320 |

Maximum bending thickness | 304 stainless steel 1.0mm | |||

Carbon steel plate 1.2mm | ||||

Aluminum plate 2.5mm | ||||

Number of axes | Customized | |||

Press-arm feeding method

Pre-feeding mode, the minimum size of the machine tool's accurate secondary positioning can be smaller and the movement is more flexible

Automatic knife series

Automatic knife series flexible panel bender

Automatic knife series, high cost performanceMachine features

Exclusive patented automatic knife splitting algorithm

Power hinge knife follow-up knife splitting, the highest comprehensive efficiency to meet various multi-variety small batch processing needs

Standard automatic knife splitting, bending auxiliary knife

Model:

RWA05-2000A/2500A

| Name | RWA05-2000A | RWA05-2500A |

| Maximum bending size(Length X Width) | 2000mmX1250mm | 2500mmX1500mm |

Maximum bending height | 170mm | |

Minimum arc radius | 2mm (depending on the thickness of the plate) | |

Dimensions(mm) | 5360*3470*3290 | 5480*4300*3300 |

Maximum bending thickness | 304 stainless steel 1.5mm | |

Aluminum plate 2.5mm | Aluminum plate 2.0mm | |

Number of axes | Customized | |

Automatic knife

Automatically adjust the tool according to the bending size of the workpiece to make it consistent with the workpiece size

Automatic knife collection

The mold will be stuck after the box-shaped workpiece is bent. This function can be used to unfold the tool after the mold is folded and the workpiece is taken out.

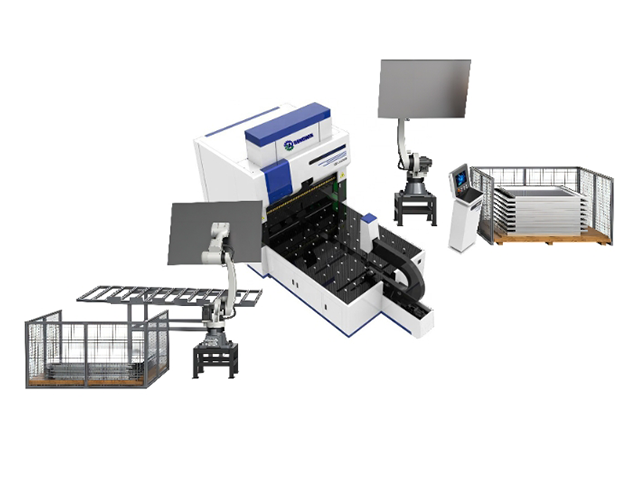

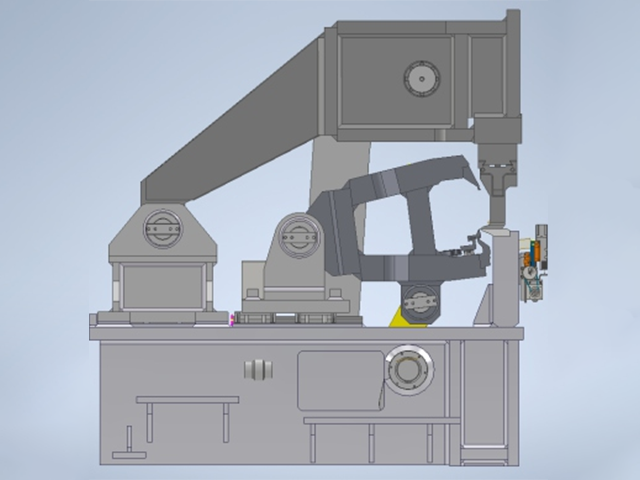

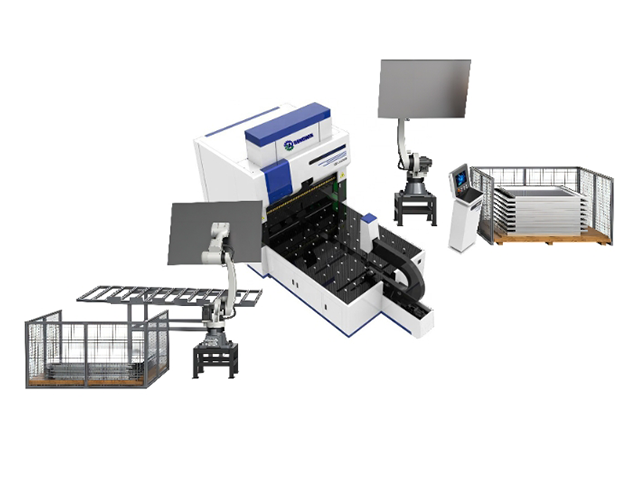

Automatic loading and unloading solution

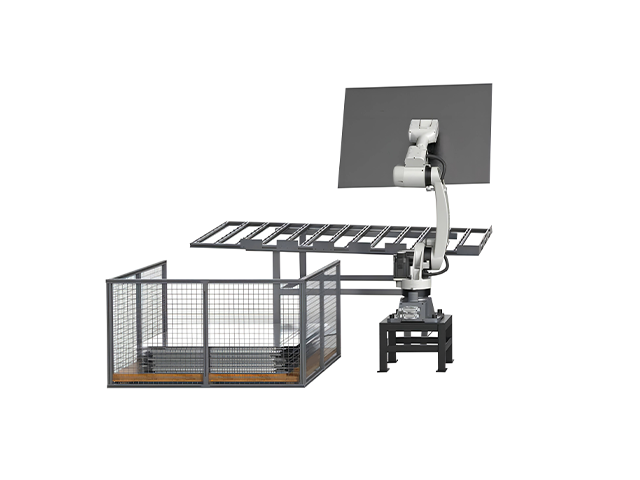

Robotic arm loading and unloading solution

Optional single robot arm/dual robot arm loading and unloading solutions

The same control system as the bending center, more worry-free maintenance

No need for secondary programming to replace workpieces, the bending action is smooth and silky

The robot arm system supports secondary development of process packages

Panel Bender in Action: Industry Applications & Success Stories

Applicable industries

Metal frame furniture

Washing machine, refrigerator casing

Microwave oven and oven casing

Bed frames and bookcases

Railway signal equipment chassis

Fences and guardrails

Decorative metal sheets

Body parts

Typical workpieces

Customer cases

Customized panel bender

Customer pain points:

- The workpiece width is only 60-70mm, which cannot be processed by industry standard equipment

- The workpiece is easy to fall off, and traditional fixtures cannot be stably transmitted

RONGWIN customized solution:

- Customized micro workpiece panel bender

- Magnetic chuck design

Smart Automation with Panel Bender: Integrated Solutions for Seamless Production

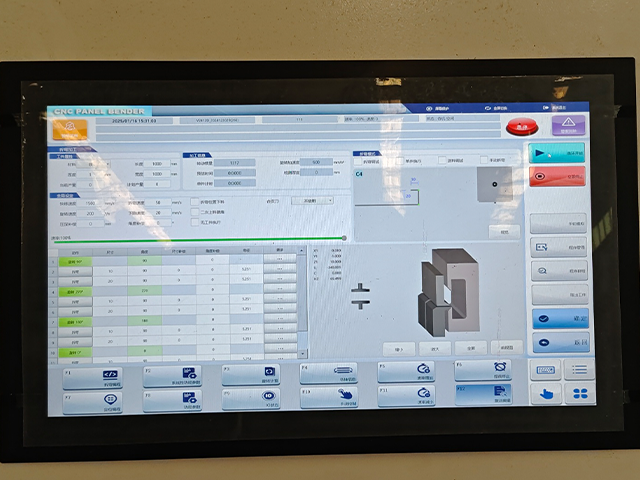

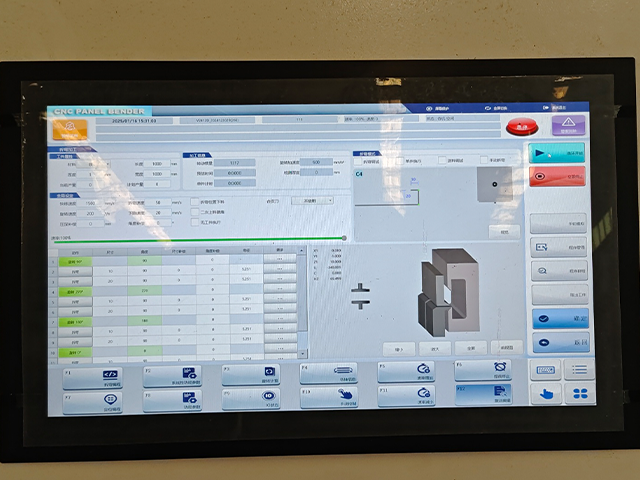

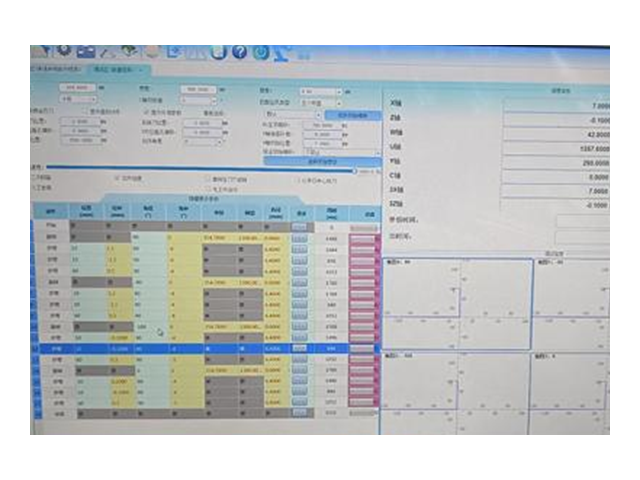

CNC system

CNC system

Simple interface, touch operation

Online upgrade

One-click data backup

Support instant power failure real-time Chinese status and alarm monitoring

19-inch large resistive touch screen

Intuitive and friendly user interface

Windows Embedded Standard 7 system

CPU: Intelcore i5-processor chip

Memory: 8G

Hard disk: 64G solid state drive

System Features

Optional: Automatic tool changing system

Optional: Auxiliary knife

Upper folding auxiliary bending knife: DL+DR

Lower folding auxiliary bending knife: UL+UR

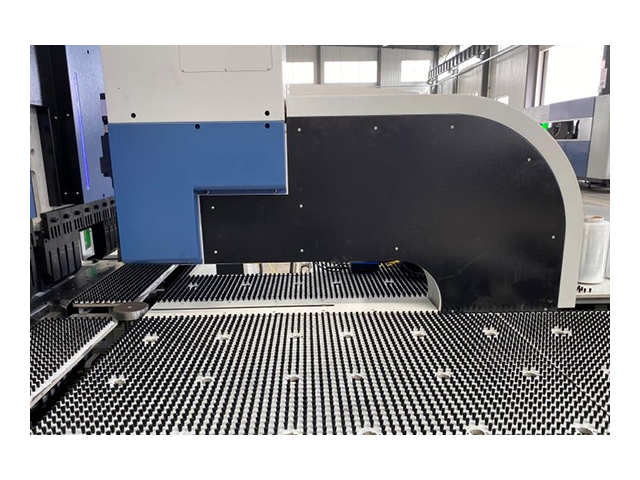

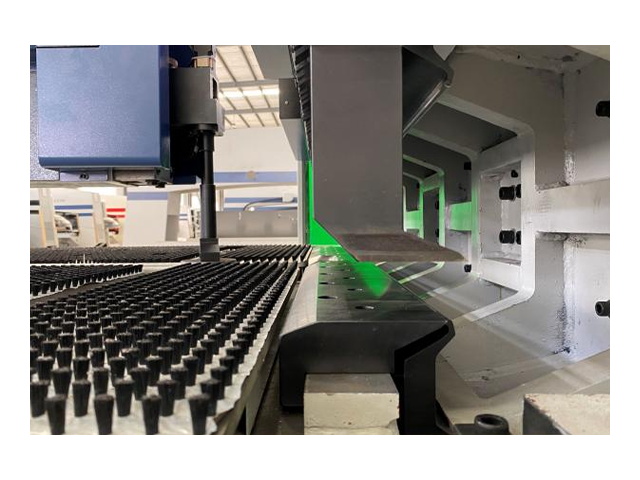

Panel Bender Full Automatic Bending Details Display

High strength frame

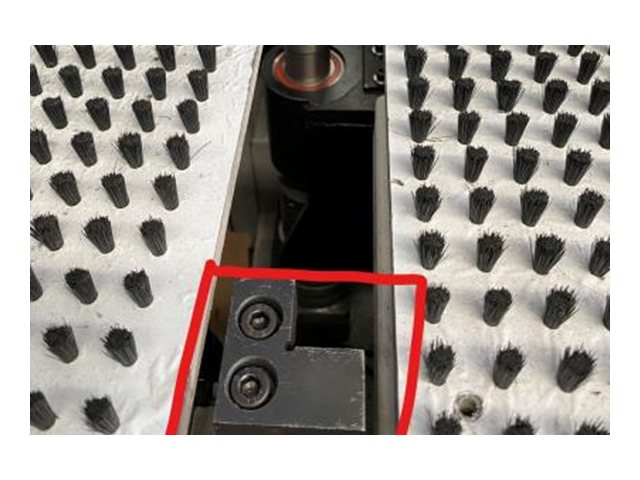

Punching tools

Positioning push device

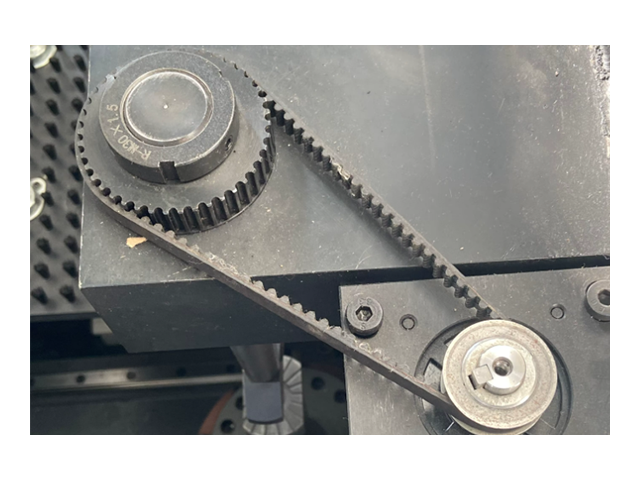

Rotating device

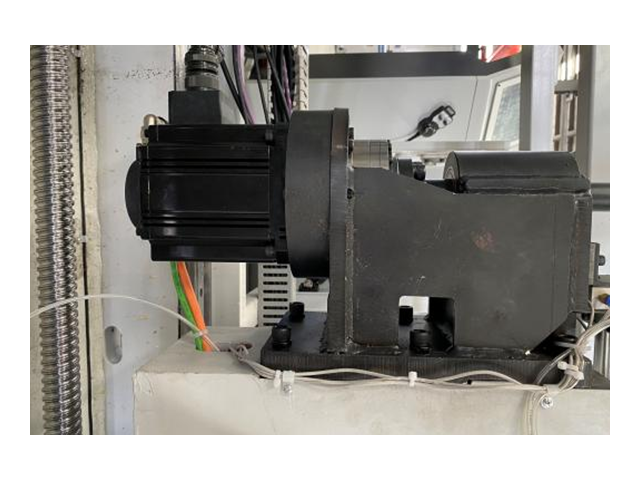

Servo drive motor

Intelligent control system

Frequency inverter

Backgauge

Panel Bender Full Automatic Bending FAQ

Q: What materials can the Panel Bender process? What is the thickness range?

A: Our panel bender supports a variety of metal materials, including stainless steel (up to 3mm), aluminum plate (up to 3.5mm), cold-rolled steel plate (up to 2.5mm), and can customize processing solutions for special materials according to needs.

Q: Can complex and special-shaped workpieces (such as arcs and closed parts) be processed? Do you need a customized mold?

A: Yes! The equipment adopts a universal mold design, and complex processing such as arcs, closed parts, and special-shaped parts can be completed without customizing molds. The patented tooling technology supports rapid mold change to meet diverse needs.

Q: How fast does the equipment run? What is the daily production capacity?

A: In high-speed mode, a single bend takes only 0.2 seconds, supporting 24-hour continuous production, and the daily production capacity can reach 3,000+ pieces (adjusted depending on the complexity of the workpiece).

Q: Can robots be integrated to achieve fully automatic loading and unloading?

A: Yes! We provide robot loading and unloading solutions linked to the panel bender, support docking with the MES system, and realize unmanned workshop production.