Rongwin Steel door production line | Improve production line efficiency

- Price

- US $108000-98000

- Model

- Rongwin Door and window manufacturing industry solutions

- MOQ

- 1 piece

Item specifics

- Place of Origin

- China Anhui

- Warranty

- 1Year

- Video outgoing-inspection

- Provided

- Weight

- 60T

- Machinery Test Report

- Provided

- Degree of oldness

- New

- Cutting length

- 350-6000mm

- Cutting angle

- ±45°90°

- Dimensions

- 20000x4000x2500mm

Review

Description

RONGWIN Door Manufacturing Industry Solutions Introduce

Machines Used to Make Doors

Emboosing Machine,Punch Machine,Press Brake,Door Frame Cutting,Laser Welding Machine,Transfer Printing Machine,Through the high-pressure pressing process, unique textures and patterns are created to enhance the visual effect of the door.

Steel Door Production Line Application Scenario

Steel Door Production Line Pain Points

1. Difficulty in cost contro

Rising costs and limited economies

of scale drive up expenses.

2. Insufficient technological innovation

Limited R&D and slow upgrades hinder

competitiveness and market adaptation.

Steel Door Production Line Advantages

1. Automation and intelligent technologies enable efficient, high-quality production with minimal

manual intervention.

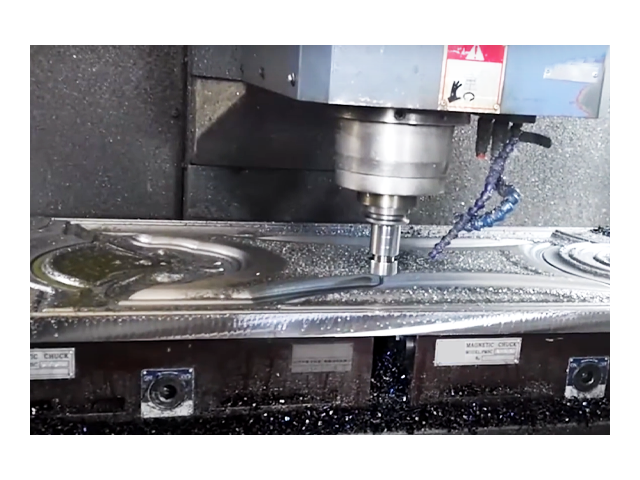

Feature 1

Our pressing machines form door panels

with precision, stability, and easy operation.

Feature 2

Our bending machines offer adjustable angles and

lengths for precise, uniform door panel bending with

minimal deformation.

Feature 3

Our punch presses ensure precise, fast,

and stable door panel punching with easy

operation.

Feature 4

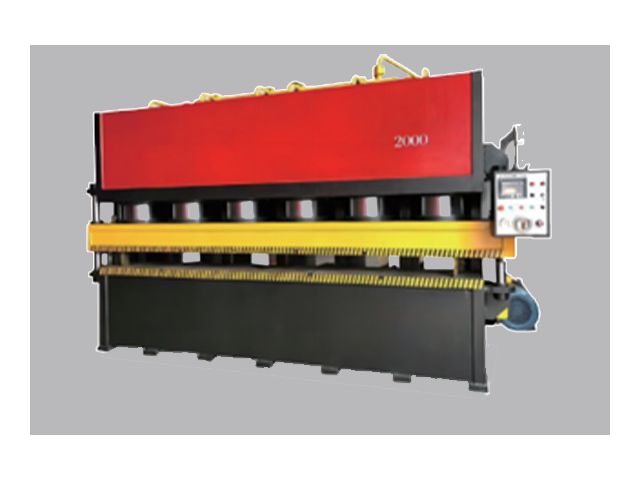

Choose a shearing machine with high precision,

speed, easy operation, and maintenance for

metal door panels.

2 . Our energy-efficient machine tools reduce costs and optimize production for higher profitability.

Feature 5

Our equipment reduces energy use, costs,

and waste while promoting environmental

responsibility.

Feature 6

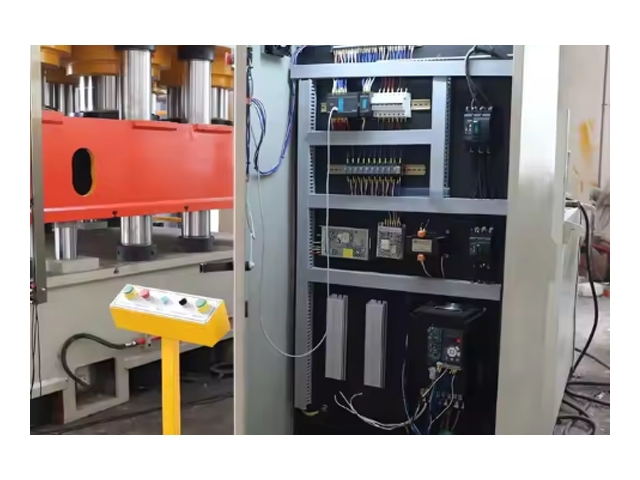

We use smart technologies like PLC control

and remote diagnostics to automate processes,

cut costs, and improve reliability.

Feature 7

We customize sheet metal equipment to customer

specs, offering options for different production

scales and budgets.

Feature 8

We customize sheet metal equipment to fit customer

specs, based on needs and budget.

Steel Door Production Line Details Display

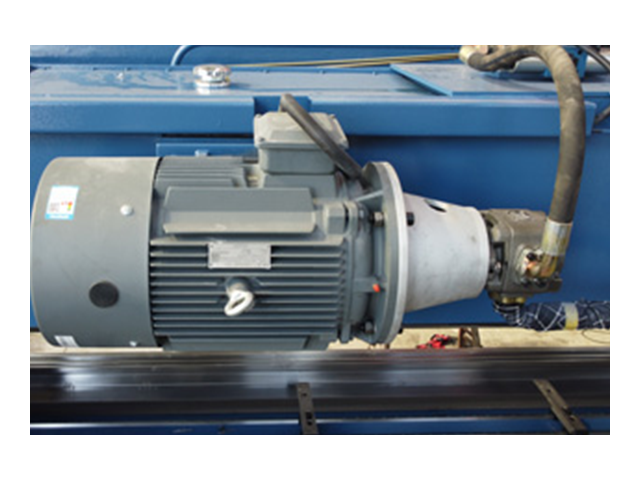

Servo system

Buffer cylinder

Sealing ring

Electrical cabinet

Pressure gauge

Water chiller

Hydraulic Valve

Main motor

Steel Door Production Line Application Machines

Door sheet production line

Production line machines

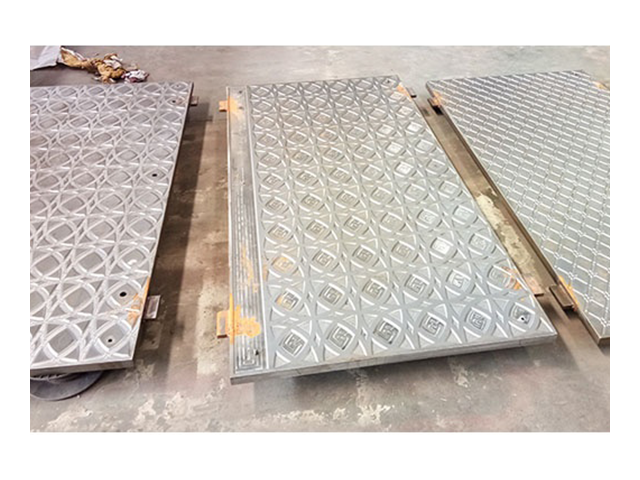

Embossing machine

Surface printing

Shearing machine

Cutting sheet

Punching machine

Drilling

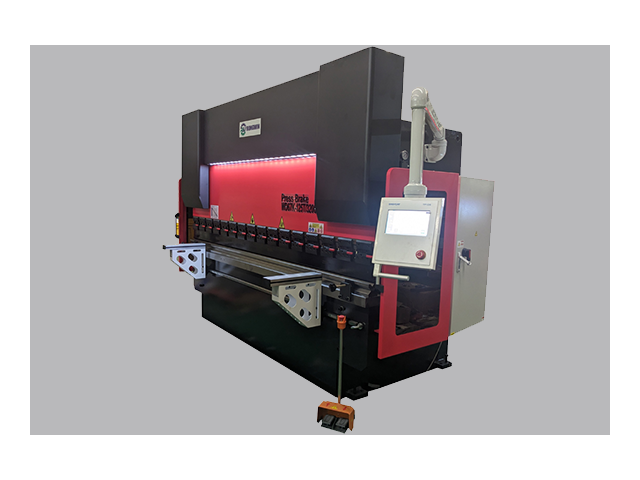

Press brake

Steel bending

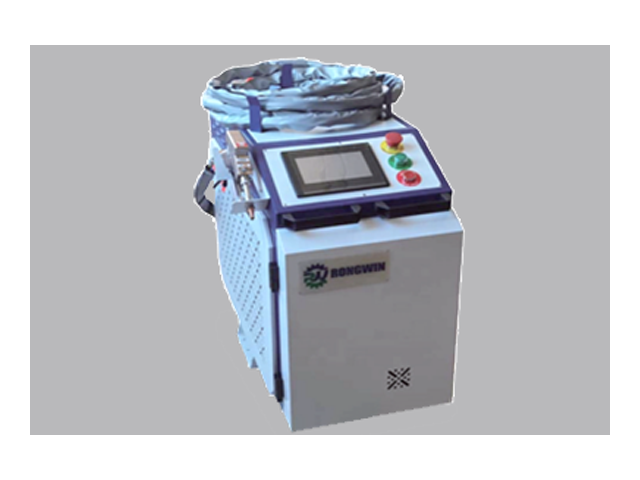

Laser welding machine

High precision welding

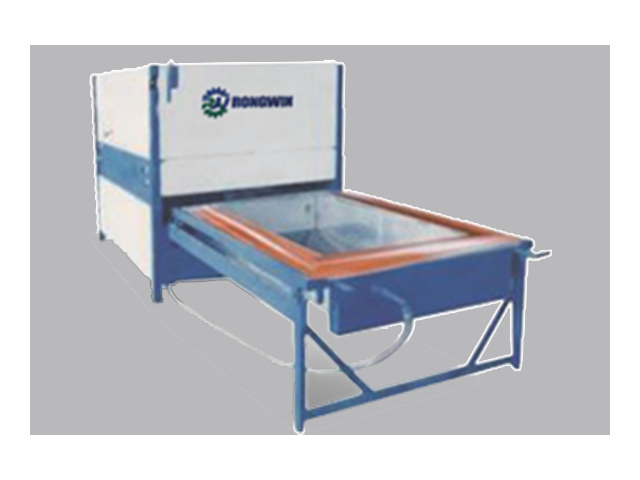

Hot press machine

Surface smooth and beautiful

Transfer printing machine

Personalized

customization

Steel Door Production Line Application Machines

Door frame production line

Production line machines

Door emboosing machine

Make various surface decorations

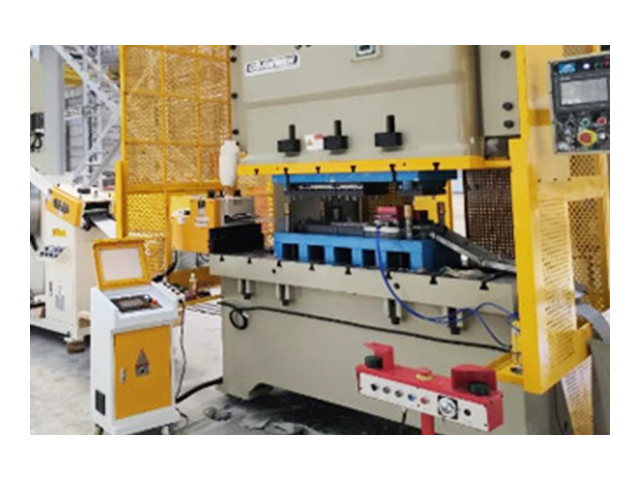

Punch machine

Drilling

Press brake

Steel bending

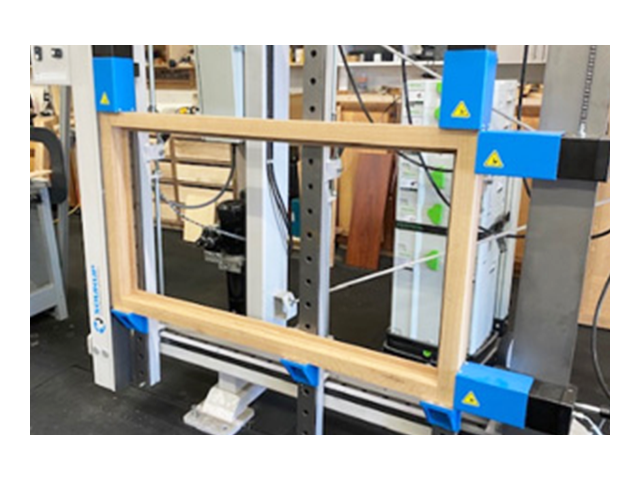

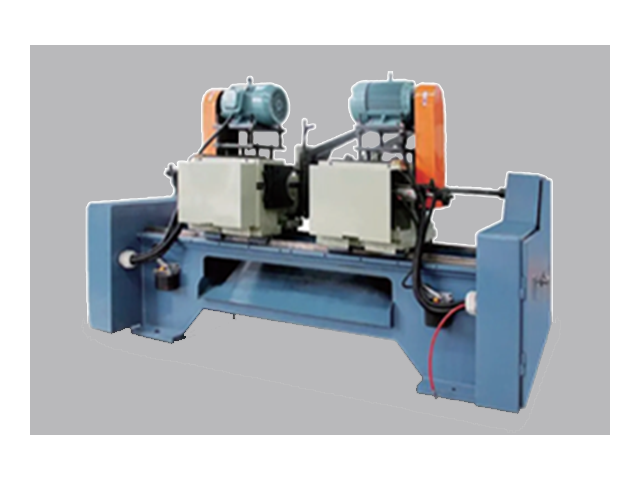

Door frame cutting machine

Precision cutting

Laser welding machine

High precision welding

Transfer printing machine

Personalized customization

Steel Door Production Line Application Machines

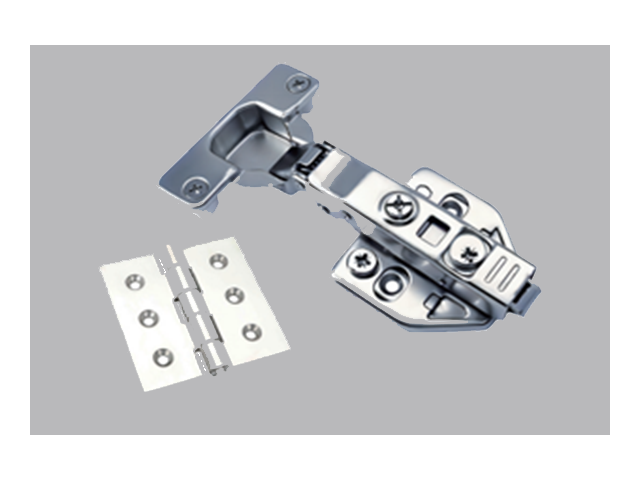

Hinge production line

Production line machines

Leveling machine

Correction of

material flatness

Uncoiler machine

Correction of

material flatness

Pneumatic punch

High-precision punching

Drill press

Drilling

Polishing machine

Make surface smooth

Assembly machine

Hinge assembly

Steel Door Production Line FAQ

How to choose a machine?

You can tell me your specifications and we can choose the best model for you. We also have some regular models for you to choose. You can also provide drawings, sizes, photos of the products, we can design a suitable machine for you according to your requirements. After the machine is finished, you can also provide samples and we will test it for you.

Why choose your company?

We can provide customized services according to customer requirements. We also have a professional R&D team and a fast-response sales team. Strictly control every step of the QA and QC system process. We have an after-sales service team that can quickly solve any problems you may encounter during use.

How is the quality of your machines? We are concerned about the quality.

Rongwin is a mature brand in China. After several years of technical research, our designs, including the safety and precision of the structure and details, have been greatly improved to meet all CE standards or more stringent standards. Our machines are sold to about 20 countries with sheet metal industries around the world, and wherever there are our machines, there is a good reputation and end-user satisfaction.

Can I send samples for testing? Do you have any testing fees?

Yes, it would be better if you can send us a sample. In order to test, we have to customize the mold according to your product, so the mold fee will be borne by you, and of course the mold belongs to you.