RONGWIN Customizable Plasma Cutting Machine |1560 Portable

- Price

- US $15000-8000

- Model

- Plasma Cutting Machine

- MOQ

- 1 piece

Item specifics

- Motor Type

- Servo Motor

- State

- New

- Country of Origin

- China

- Warranty

- 3 Years

- Core selling Point

- Competitive Price

- Marketing Type

- New Product 2024

- Mechanical Test RWeport

- Provided

- Video Factory Inspection

- Provided

- Core Component Warranty Period

- 1 Year

- Core Components

- Bearing Pump Gear Motor

- Province

- Anhui

- Model

- plasma cutting machine

Review

Description

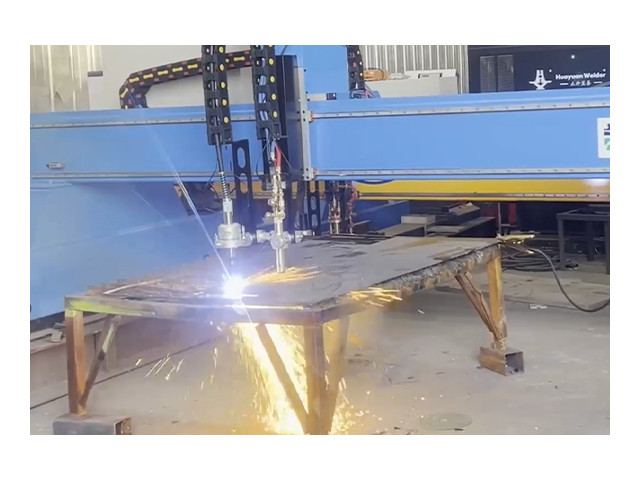

Plasma Cutting Machine Introduction

RONGWIN Plasma Cutting Machines: Versatile Solutions for Precision Metal Cutting

Plasma cutting machine is a highly efficient automated cutting equipment, which applies to all kinds of carbon steel, stainless steel, as well as precision sheet metal cutting non-ferrous metals. Widely used in sheet metal manufacturer of metal materials and advertisement industry word or cutting of metal crafts.

RONGWIN produces three types of plasma cutting machines, customers can choose according to their needs. They are portable plasma cutting machine, gantry plasma cutting machine, bench plasma cutting machine.

Plasma Cutting Machine Application Scenario

Advantages

Feature 1

Table Type CNC Plasma Cutting Machine

1. Sturdy welded steel bed and optimized lathe design ensure durability and stability.

2. Advanced material discharging system and FastCAM software improve workflow efficiency.

3. Precision-driven by a stepper motor and helical rack system, with THC for consistent performance.

Feature 2

Portable CNC Plasma Cutting Machine

1. Combines portability with precision, featuring tailored tracks for high-speed, accurate cutting.

2. Supports flame and plasma cutting modes, with dynamic Torch Height Control (THC) ensuring optimal cut quality and torch longevity.

3. User-friendly interface, multi-language support, and CAD compatibility make it versatile and easy to use.

Feature 3

Gantry Type CNC Plasma Cutting Machine

1. Robust crossbeam and precision rack-and-pinion system ensure reliable operation.

2. Features like automatic ignition, solenoid valve optimization, and expert programming software enhance cutting accuracy and productivity.

3. Designed for efficiency, it reduces material waste and operating costs.

Table Type CNC Plasma Cutting Machine Technical Parameters

Table Type CNC Plasma Cutting Machine offers a variety of models, covering a variety of needs from small to large, the specific technical parameters range as follows:

Process area | 1300*2500mm/1500*3000mm /2000*4000mm(Have special requirements can be customized) |

|

Cutting speed

|

0-8000mm/min

|

Processing precision | 0.1mm |

Reposition precision | 0.02mm |

Torch Height control mode | Automatic |

File Transfer mode | USB interface |

Air pressure | 0.3-0.5Mpa |

Work way | Contact/non-contact |

|

Control system

|

STARfire

|

|

Cooling method

|

Air + water sniper

|

|

Drive

|

Stepper driver

|

Plasma Air Pressure | Max.0.8Mpa |

LCD Display Dimension | 7 Inches |

Parameters within this range reflect the wide applicability of the Table Type CNC Plasma Cutting Machine in different application scenarios, from small and medium-sized precision processing to large-scale industrial manufacturing.

Gantry Type CNC Plasma Cutting Machine

Gantry Type CNC Plasma Cutting Machine offers a variety of models, covering a variety of needs from small to large, the specific technical parameters range as follows:

Model | EffectiveWidth ForCutting(mm) | EffectiveLength ForCutting(mm) | Suitable Cut Material(PLASMA) | Suitable Cut Material (FLAME) |

|

RWZ1520FP

|

1500 | 2000 | Mild steel Stainless steel Aluminum |

Mild steel (6-200mm)

|

RWZ1530FP | 1500 | 3000 | Mild steel Stainless steel Aluminum | Mild steel (6-200mm) |

RWZ1560FP | 1500 | 6000 | Mild steel Stainless steel Aluminum | Mild steel (6-200mm) |

RWZ2230FP | 2200 | 3000 | Mild steel Stainless steel Aluminum | Mild steel (6-200mm) |

RWZ2260FP | 2200 | 6000 | Mild steel Stainless steel Aluminum | Mild steel (6-200mm) |

RWZ2630FP | 2600 | 3000 | Mild steel Stainless steel Aluminum | Mild steel (6-200mm) |

RWZ2660FP | 2600 | 6000 | Mild steel Stainless steel Aluminum | Mild steel (6-200mm) |

|

RWZ2690FP

|

2600 | 9000 | Mild steel Stainless steel Aluminum |

Mild steel (6-200mm)

|

Parameters within this range reflect the wide applicability of the Gantry Type CNC Plasma Cutting Machine in different application scenarios, from small and medium-sized precision processing to large-scale industrial manufacturing.

Portable CNC Plasma Cutting Machine

Portable CNC Plasma Cutting Machine offers a variety of models, covering a variety of needs from small to large, the specific technical parameters range as follows:

Model | Effective Width For Cutting(mm) | Effective Length For Cutting(mm) | Suitable Cut Material(PLASMA) | Suitable Cut Material (FLAME) |

|

HCB1220FP

|

1200 | 2000 | Mild steel Stainless steel Aluminum |

Mild steel (6-200mm)

|

HCB1230FP | 1200 | 3000 | Mild steel Stainless steel Aluminum | Mild steel (6-200mm) |

HCB1520FP | 1500 | 2000 | Mild steel Stainless steel Aluminum | Mild steel (6-200mm) |

HCB1530FP | 1500 | 3000 | Mild steel Stainless steel Aluminum | Mild steel (6-200mm) |

HCB1840FP | 1800 | 4000 | Mild steel Stainless steel Aluminum | Mild steel (6-200mm) |

Parameters within this range reflect the wide applicability of the Portable CNC Plasma Cutting Machine in different application scenarios, from small and medium-sized precision processing to large-scale industrial manufacturing.

Plasma Cutting Machine Details Display

Helical rack and pinion

Controller

HIWIN Square guide rails

Motor

Plasma Cutting Machine FAQ

1. What is a plasma cutting machine?

A plasma cutting machine uses an electric arc and compressed gas (such as air, oxygen, or nitrogen) to create a high-temperature plasma jet, capable of cutting through electrically conductive materials like steel, stainless steel, aluminum, and copper.

2. What materials can a plasma cutter cut?

Plasma cutters are designed for conductive metals such as:

Mild steel

Stainless steel

Aluminum

Copper

Brass

What are the advantages of CNC plasma cutting machines?

Precision: Accurate cuts with minimal material waste.

Speed: Faster than traditional cutting methods like oxy-fuel.

Versatility: Can cut various thicknesses and materials.

Ease of Use: CNC programming allows for detailed and complex cuts.

What is the difference between a portable and a stationary plasma cutter?

Portable Plasma Cutters: Lightweight and compact, suitable for on-site and small-scale applications.

Stationary Plasma Cutters: Larger and more powerful, ideal for industrial or high-volume use.