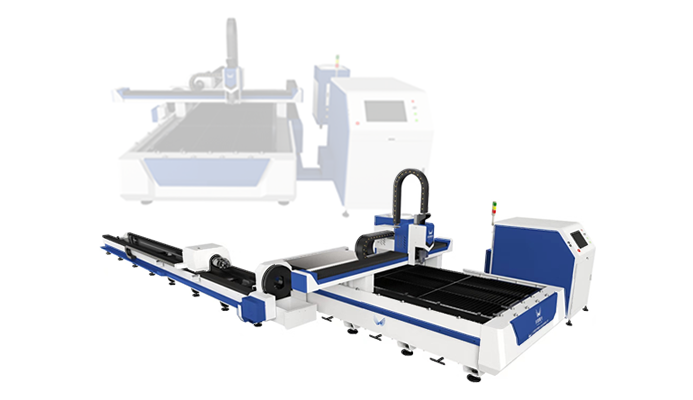

RONGWIN Customizable plate & pipe cutting machine | Stainless Steel Fiber 3000w

- Model

- Laser Cutting Machine CNC Cutting with Pipe Machine

Item specifics

- Laser Type

- Fiber Laser

- Applying Materials

- Metal Laser Cutting Machine

- Degree of Oldness

- New

- Country of Origin

- China

- Industrial Laser Brand

- IPG

- Core Selling Point

- Long Service Life

- Warranty

- 3 Years

- Province

- Anhui

- Cooling Method

- Water Cooling

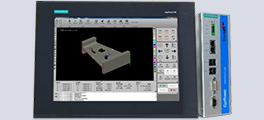

- Laser Machine Control System Brand

- Cypcut

Review

Description

Innovative Fiber Laser Cutting Machines for Modern Metal Fabrication

With over a decade of experience in sheet metal fabrication, RONGWIN specializes in advanced fiber laser cutting machines that integrate both plate and tube processing. Our commitment to innovation and precision makes us a reliable choice for global manufacturers seeking efficiency and quality.

Customer Benefits with Fiber Laser Cutting Solutions

Many manufacturers face issues such as slow processing speeds, excessive waste, and inconsistent quality. RONGWIN's fiber laser machines directly address these pain points:

Save delivery time, improve delivery efficiency, and gain market competitive advantage.

Ensure precision, reduce material waste and lower production costs.

The entire training time can be shortened, labor costs can be reduced, and operational efficiency can be improved.

Reduce time, increase productivity, and ensure stable and continuous operation.

Core Features and Advantages of Fiber Laser Cutting Machine

Our fiber laser cutting machine is designed for versatile applications, from stainless steel to carbon steel and aluminum alloys.Meet various cutting needs.

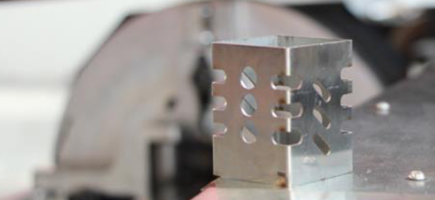

Technical Specifications and Proven Performance

Every RONGWIN laser cutting machine for metal undergoes strict quality testing to ensure durability and consistency. Trusted by global customers, our machines combine robust engineering with advanced technology.

Product details display

Mechanical Bed

Made of high-strength steel to ensure mechanical stability and precision

Beam

Lightweight design and high-speed movement ensure cutting efficiency

Laser Source

High power fiber laser, low power consumption and long service life

Cutting Head

Precision optical system, automatic focusing, excellent cutting quality

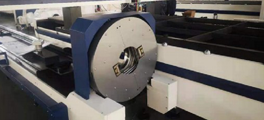

Pneumatic chuck Design

Automatic handling system, suitable for various pipe specifications

Control System

Intelligent CNC system, simple operation and powerful functions

Technical Specifications

| Type | RWLG-3015G | RWLG-4015G | RWLG-4020G | RWLG-6015G | RWLG-6020G | RWLG-6322G | RWLG-6325G | RWLG-8325G | RWLG-130225G |

|---|---|---|---|---|---|---|---|---|---|

| Plate processing range | 3000*1500mm | 4000*1500mm | 4000*2000mm | 6000*1500mm | 6000*2000mm | 6300*2200mm | 6300*2500mm | 8300*2500mm | 13000*2500mm |

| X-axis travel | 1500mm | 1500mm | 2000mm | 1500mm | 2000mm | 2200mm | 2500mm | 2500mm | 2500mm |

| Y-axis travel | 3000mm | 4000mm | 4000mm | 6000mm | 6000mm | 6300mm | 6300mm | 8300mm | 13000mm |

| Z-axis travel | 100mm | ||||||||

| Laser power(W) | 1500/2000/3000/4000/6000/8000/10000/12000/15000/20000/30000/others | ||||||||

| Cut pipe length | 6000mm/9000mm/12000mm+others | ||||||||

| Cutting pipe diameter | Φ165/Φ220/Φ350/others | ||||||||

| X/Y-axis positioning accuracy | ≤±0.03mm | ||||||||

| X/Y-axis repeat positioning accuracy | ≤±0.02mm | ||||||||

| Maximum positioning speed | 120m/min | ||||||||

Processing scope and capability

Flat cutting.

Steel structure industry, power and electrical, transportation, rail transit, shipbuilding, engineering machinery, agricultural machinery, elevator and garage, household appliances, textile machinery, industrial and petroleum machinery, clean energy industry, food machinery, kitchenware and bathroom, decorative advertising, sheet metal processing, laser external processing services, etc.

All metal materials including high carbon steel, low carbon steel, stainless steel, aluminum alloy, brass, pickled plate, galvanized plate, silicon steel plate, electrolytic plate, titanium alloy, manganese alloy, nickel plate, etc.

FAQ

A1: It can cut stainless steel, carbon steel, aluminum, brass, and more. As a reliable laser cutter machine for metal, it ensures stable and precise performance.

A2: Fiber laser cutting machines are faster, more energy-efficient, and provide higher precision compared to CO2 machines, especially for thin to medium-thickness metals.

A3: Yes. The machine is equipped with a smart CNC control system, making operation and training simple.