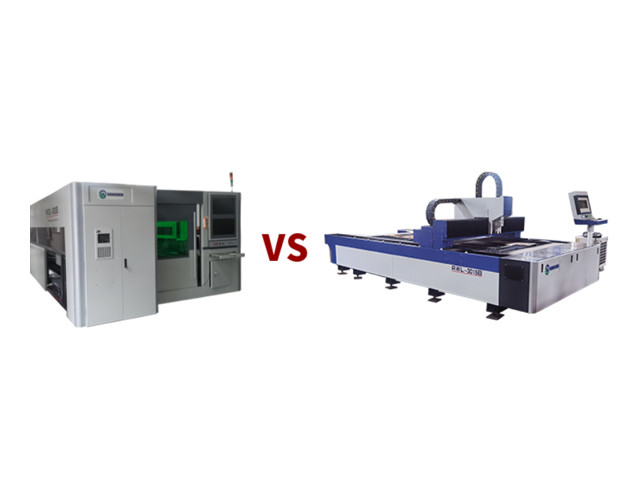

Double Table Seal Fiber Laser Cutting Machine | 6000W Power Metal Component Exchange Table Design

- Price

- US $5000-4800

- Model

- Double table seal fiber laser cutting machine

- MOQ

- 1 piece

Item specifics

- Laser Type

- Fiber Laser

- Applying Materials

- Metal Fiber Laser Metal Cutting Machine

- Degree of Oldness

- New

- Country of Origin

- China

- Industrial Laser Brand

- IPG

- Core Selling Point

- Long Service Life

- Warranty

- 3 Years

- Operation Mode

- Continuous Wave

- Configuration

- Gantry Type

Review

Description

Double Table Seal Fiber Laser Cutting Machine

As a versatile laser cutting solution, it efficiently processes plates, tubes, and various metals like galvanized steel and alloys. It is widely adopted in kitchenware, electrical enclosures, auto parts, and metal fabrication for superior results.

Customer Benefits with Double Table Seal Fiber Laser Cutting Machine

In the metal processing industry, manufacturers often face pain points such as slow processing speeds, high material waste, inconsistent cutting quality, high long-term operating costs, and high operator skill thresholds. The Rongwin Customizable Fiber Laser Cutting Machine provides targeted solutions for these issues, delivering tangible benefits to buyers:

With a maximum positioning speed of 120m/min and an acceleration of 1.2G, it reduces the cutting time of large-size metal plates (e.g., 6000×2000mm carbon steel) by 30% compared to traditional fiber laser cutters. For batch production of 100 sets of automotive chassis parts, the production cycle can be shortened from 5 days to 3.5 days.

X/Y-axis positioning accuracy ≤±0.03mm and repeat positioning accuracy ≤±0.02mm (calibrated by laser interferometer). The cutting edges are burr-free and have no oxidation layer, eliminating the need for secondary grinding processes. This reduces post-processing costs by 25% and lowers the defect rate to less than 0.5%.

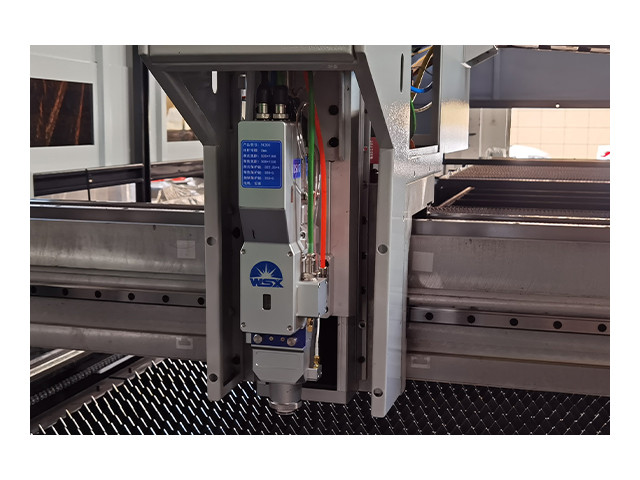

Equipped with high-precision CNC control and automatic focus cutting head (Raytools), it can stably cut complex patterns such as curved surfaces, hollowouts, and micro-holes (minimum hole diameter 0.5mm), meeting the precision requirements of aerospace and electronic component industries.

Core Features and Advantages of Fiber Laser Welding Machine

Engineered for both small workshops and high-volume production, the RONGWIN fiber laser welding machine provides a series of powerful benefits:

Technical Specifications and Proven Performance

Every RONGWIN Handheld Laser Welding Machine undergoes strict quality testing to ensure durability and consistency. Trusted by global customers, our machines combine robust engineering with advanced technology.

Product details display

Automatic iubrication device

Control system

Laser cutting head

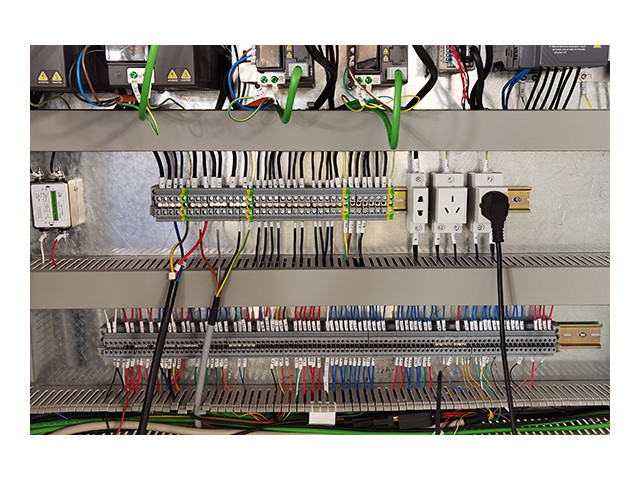

Electrical cabinet

Technical Specifications

| Type | RWZL-3015B | RWZL-4015B | RWZL-4020B | RWZL-6015B | RWZL-6020B | RWZL-6322B | RWZL-6325B | RWZL-8322B | RWZL-8325B | RWZL-13025B |

|---|---|---|---|---|---|---|---|---|---|---|

| Processing range | 3000*1500mm | 4000*1500mm | 4000*2000mm | 6000*1500mm | 6000*2000mm | 6300*2200mm | 6300*2500mm | 8300*2200mm | 8300*2500mm | 13000*2500mm |

| X-axis travel | 1500mm | 1500mm | 2000mm | 1500mm | 2000mm | 2200mm | 2500mm | 2200mm | 2500mm | 2500mm |

| Y-axis travel | 3000mm | 4000mm | 4000mm | 6000mm | 6000mm | 6300mm | 6300mm | 8300mm | 8300mm | 13000mm |

| Z-axis travel | 250mm | |||||||||

| Laser power(W) | 1500/2000/3000/4000/6000/8000/10000/12000/15000/20000/30000/others | |||||||||

| X/Y-axis positioning accuracy | ≤±0.03mm | |||||||||

| X/Y-axis repeatability positioning accuracy | ≤±0.02mm | |||||||||

| Maximum positioning speed | 120m/min | |||||||||

Cutting Applications

two-dimensional plane cutting.

teel structure industry, power and electrical, transportation, rail transit, ship manufacturing, construction machinery, agricultural machinery, elevator garage, household appliances, textile machinery, petroleum machinery, clean energy industry, food machinery, kitchen utensils and bathrooms, decoration advertising, sheet metal processing, laser external processing services, etc.

high-carbon steel, low-carbon steel, stainless steel, aluminum alloy, brass, pickled plates, galvanized plates, silicon steel plates, electrolytic plates, titanium alloys, manganese alloys, nickel plates and other metal materials.

FAQ

A1: The machine is designed for cutting a range of metals, including stainless steel, carbon steel, aluminum, and brass.

A2: The dual-exchange worktable allows for simultaneous loading and cutting, minimizing downtime and increasing productivity.

A3: Yes, the sealed structure enhances operator safety by controlling dust and emissions during operation.

A4: It is ideal for applications in automotive, aerospace, metal fabrication, and other industries requiring high-speed, precision cutting.