Rongwin Customizable Fiber Laser Cutting Machine | Metal Stainless Steel Cutting

- Price

- US $100000-30000

- Model

- fiber laser cutting machine

- MOQ

- 1 piece

Item specifics

- Laser Type

- Fiber Laser

- Applying Materials

- Metal Fiber laser Cutting Machine

- Degree of oldness

- New

- Country of origin

- China

- Industrial laser brand

- IPG

- Core selling point

- Long Service Life

- Warranty

- 3 years

- Operation Mode

- Pulsed

- Configuration

- Gantry Type

- Product handling

- Sheet Metal and Tube

Review

Description

CNC Fiber Laser Metal Cutter

This equipment integrates an advanced international fiber laser and a digital control system for precise, high-speed cutting of various metals. It is ideal for processing stainless steel, carbon steel, and alloy plates, widely serving industries from automotive parts to kitchen appliances.

Customer Benefits with CNC Fiber Laser Metal Cutter

Many manufacturers face issues such as slow processing speeds, excessive waste, and inconsistent quality. RONGWIN's Fiber Laser Metal Cutter directly address these pain points:

The RONGWIN fiber laser cutter for metal offers fast cutting speed and high accuracy. It creates clean edges and tight tolerances on stainless steel, carbon steel, aluminum, brass, and other metals.

Our CNC laser metal cutter comes with laser power options from 1kW to 12kW. It also has adjustable bed sizes. This allows manufacturers to pick the best setup for their production needs and budget.

This laser cutting system has a high-efficiency fiber laser and a smart design. It uses less energy, needs little maintenance, and lasts over 100,000 hours.

The RONGWIN fiber laser machine has an easy-to-use touch screen. Its smart nesting software makes operation simple. This helps operators of all skill levels learn quickly.

Core Features and Advantages of Fiber Laser Welding Machine

The RONGWIN fiber laser welding machine is designed for small workshops and large production. It offers many powerful benefits:

Technical Specifications and Proven Performance

Every RONGWIN Fiber Laser Metal Cutter undergoes strict quality testing to ensure durability and consistency. Trusted by global customers, our machines combine robust engineering with advanced technology.

Product details display

Laser head

Cooling system

Cooling fan

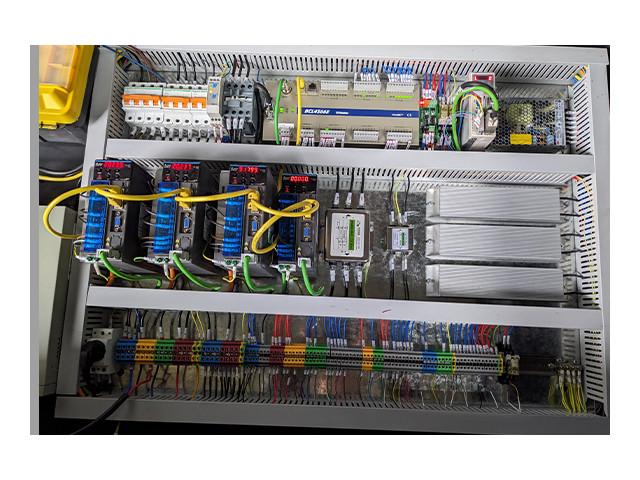

System

Electrical cabinet

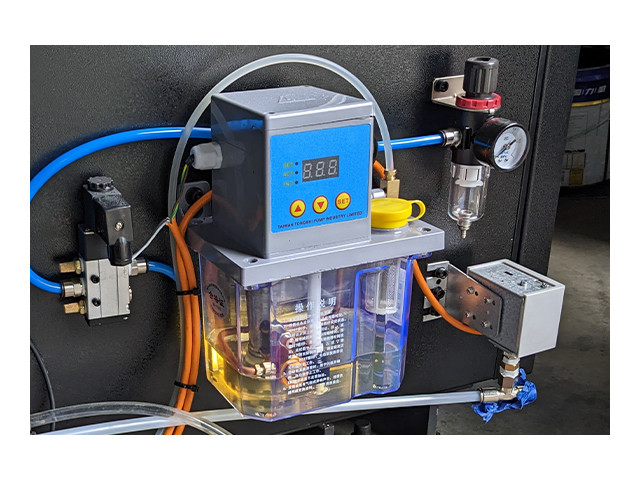

Automatic lubrication device

Power switch

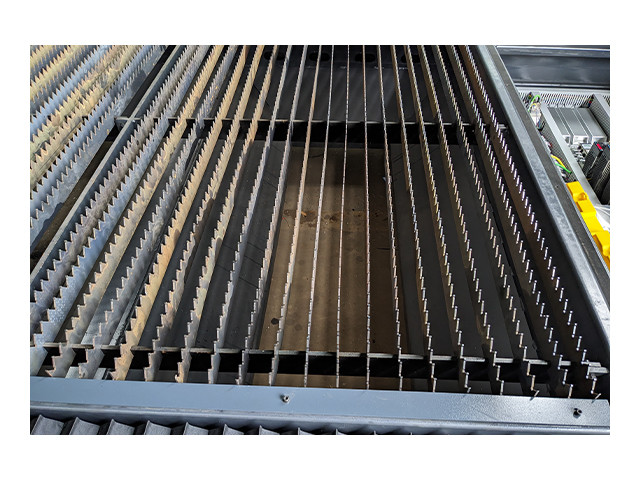

Workbench

Technical Specifications

| Type | RWL-3015B | RWL-4015B | RWL-4020B | RWL-6015B | RWL-6020B | RWL-6322B | RWL-6325B | RWL-8322B | RWL-8325B | RWL-130225G |

|---|---|---|---|---|---|---|---|---|---|---|

| Processing range | 3000*1500mm | 4000*1500mm | 4000*2000mm | 6000*1500mm | 6000*2000mm | 6300*2200mm | 6300*2500mm | 8300*2200mm | 8300*2500mm | 13000*2500mm |

| X-axis travel | 1500mm | 1500mm | 2000mm | 1500mm | 2000mm | 2200mm | 2500mm | 2200mm | 2500mm | 2500mm |

| Y-axis travel | 3000mm | 4000mm | 4000mm | 6000mm | 6000mm | 6300mm | 6300mm | 8300mm | 8300mm | 13000mm |

| Z-axis travel | 140mm | |||||||||

| Laser power(W) | 1500/2000/3000/4000/6000/8000/10000/12000/15000/20000/30000/others | |||||||||

| X/Y-axis positioning accuracy | ≤±0.03mm | |||||||||

| X/Y-axis repeat positioning accuracy | ≤±0.02mm | |||||||||

| Maximum positioning speed | 120m/min | |||||||||

Cuting Applications

The RONGWIN CNC fiber laser cutting machine is engineered for a wide range of cutting environments.

It delivers precise, high-speed cutting for flat sheet metal, perforated plates, and complex custom patterns.

From large industrial plates to small decorative parts, the machine maintains smooth edges and minimal heat distortion, ensuring clean kerf quality even on intricate shapes and tight spaces.

This advanced fiber laser cutter for metal supports multiple manufacturing sectors that require accuracy and efficiency, including:

1.Automotive and Aerospace – body panels, chassis components, aircraft parts

2.Metal Fabrication – custom furniture, architectural panels, elevator and stair parts

3.Electronics and Appliances – enclosures, cooling vents, precision hardware

4.Advertising and Signage – stainless steel letters, illuminated signs, custom logos

5.Construction and Architecture – railings, wall panels, structural plates

Its versatility allows job shops, OEMs, and fiber laser manufacturers to expand production capacity across diverse applications.

The RONGWIN fiber laser cutter offers clean, burr-free cutting across a variety of industrial metals, including:

1.Stainless Steel and Carbon Steel – capable of cutting up to 20 mm depending on power

2.Aluminum and Copper – stable performance for high-reflective materials

3.Brass and Titanium – precision cutting for decorative and structural parts

4.Mild Steel and Alloy Plates – smooth finishes with minimal secondary processing

This wide material compatibility ensures manufacturers can handle everything from lightweight decorative pieces to heavy-duty industrial components with a single laser cutting machine.

FAQ

A1: Fiber Laser Cutting Machines can cut many types of materials. These include metals like carbon steel, stainless steel, aluminum, and brass. They can also cut non-metals such as acrylic, wood, plastics, and glass, as well as some textiles. The specific materials depend on the type and power of the laser.

Laser cutting uses a focused laser beam. It melts, burns, or vaporizes material along a set path. This method creates precise cuts and detailed designs. CNC technology typically controls the process.

A3: High precision and accuracy

Ability to cut complex shapes and fine details

Minimal material waste

Non-contact cutting reduces wear and tear on tools

Faster processing speeds compared to traditional methods

A4: Common types of lasers include CO₂ lasers, which are great for non-metals. Fiber lasers work best for metals and some non-metals. Diode lasers are used in smaller machines for specific tasks.