RONGWIN Customizable Pneumatic Folding Machine | Aluminum, Stainless Steel and Carbon Steel

- Price

- US $2000-800

- Model

- Pneumatic Folding Machine

- MOQ

- 1 piece

Item specifics

- Video factory inspection

- Provided

- Mechanical test report

- Provided

- Marketing type

- Ordinary Product

- Core component warranty period

- 1 Year

- Core Components

- PLC/Engine/Bearing/Gearbox

- Degree of oldness

- New

- country of origin

- China

- Warranty

- 1 Year

- Core selling point

- Competitive Price

Review

Description

Pneumatic Folding Machine Introduction

Pneumatic Folding Machine: Efficient and Easy Steel Plate Bending Solution

This machine adopts an all-steel welded structure and uses pneumatics as a power source. According to specifications, it is mostly used for bending steel plates with a length of less than 3 meters and a thickness of 0.3-2mm to achieve the purpose of forming. This machine tool is easy and fast, and the operation is simple and convenient.

It and common plate flange machine, shearing machine, five-wire bar press, bite machine and so on constitute the common plate flange air pipe semi-automatic production line, can greatly improve the production efficiency and product quality.

Pneumatic Folding Machine Application Scenario

Pneumatic Folding Machine Advantages

Feature 1

Eccentric wheel clamping device

The pneumatic folding machine adopts the improved eccentric wheel clamping device, which makes the clamping speed of the board fast and firm, and the bending efficiency is good.

Feature 2

Foot switch

Two foot switches, one for pressing and releasing the workpiece, the other for bending, simple operation and high efficiency

Pneumatic Folding Machine Technical Parameters

Pneumatic Folding Machine offers a variety of models, covering a variety of needs from small to large, the specific technical parameters range as follows:

Model | Platethickness | Mini. angleof folding plate | Distance | Max. plate length | Weight | Dimensions |

QDF-1.5*1300 | 0.3-1.5mm | 60° | 60mm | 1300mm | 360kg | 1980*800*1320m |

QDF-1.5*1500 | 0.3-1.5mm | 60° | 60mm | 1500mm | 380kg | 2180*800*1320m |

QDF-1.5*2000 | 0.3-1.5mm | 60° | 60mm | 2000mm | 440Kg | 2680*800*1320m |

QDF-1.5*2500 | 0.3-1.5mm | 60° | 60mm | 2500mm | 560kg | 3180*800*1320m |

|

QDF-1.3*3000

|

0.3-1.2mm

|

60° |

60mm

|

3000mm | 680kg |

3060*800*1590m

|

Parameters within this range reflect the wide applicability of the Pneumatic Folding Machine in different application scenarios, from small and medium-sized precision processing to large-scale industrial manufacturing.

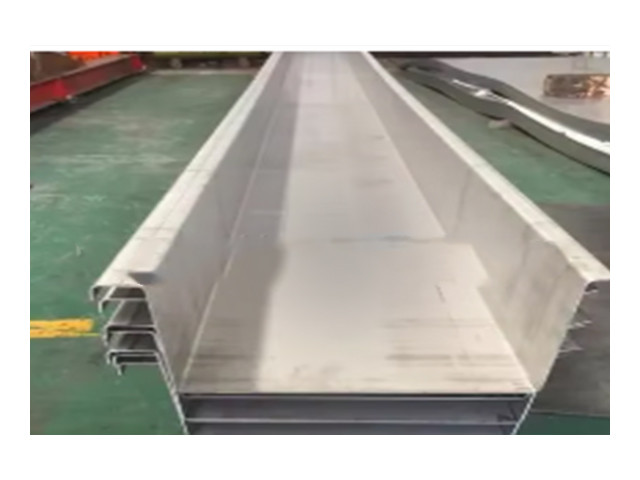

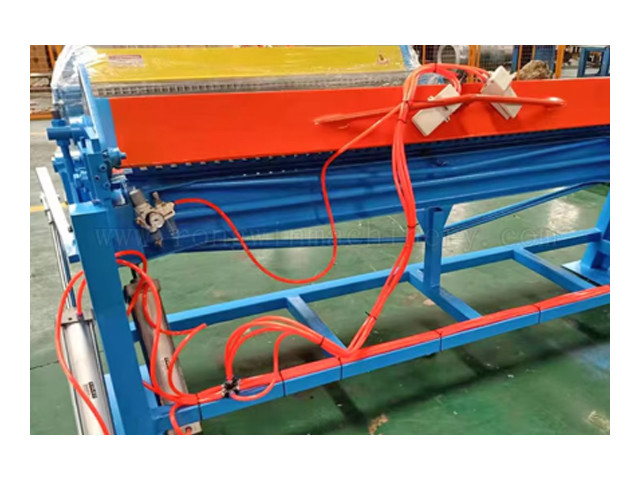

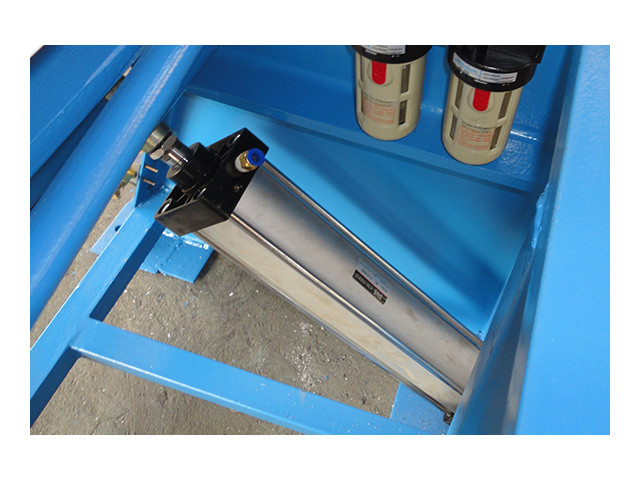

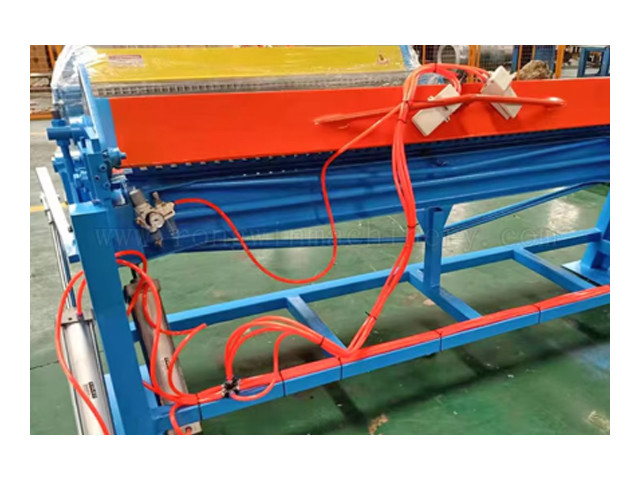

Pneumatic Folding Machine Details Display

Cylinder

Eccentric wheel clamping device

Foot switch

Folding machine blades

Pneumatic Folding Machine FAQ

What is a pneumatic folding machine?

A pneumatic folding machine is a sheet metal tool that uses compressed air to power its bending operations. It is designed for folding edges or creating precise angles in materials like steel, aluminum, and copper.

What are the advantages of using a pneumatic folding machine?

Efficiency: Faster folding operations compared to manual methods.

Consistency: Ensures uniform bends across multiple pieces.

Ease of Use: Requires minimal manual effort.

Compatibility: Works with various materials and thicknesses.

What materials can it handle?

Pneumatic folding machines are typically compatible with metals such as:

Steel

Aluminum

Copper

Other non-ferrous metals, depending on machine specifications.

What are common applications?

HVAC ductwork production

Metal fabrication shops

Construction projects

Creating enclosures, panels, or frames.