RONGWIN Hydraulic CNC angle steel production line | Applied to sheet metal stamping and cutting

- Price

- US $100000-30000

- Model

- CNC angle steel production line

- MOQ

- 1 piece

Item specifics

- Brand Name

- RONGWIN

- Voltage

- 220v 380v

- Dimension(L*W*H)

- 6900X1450X1900

- Power Source

- Hydraulic

- Model

- RWJYK-8*6000

- Application

- Metal Sheet Stamping

- Advantage

- Higher Accuracy and Easy Operation

Review

Description

CNC Angle Steel Production Line Introduction

New CNC Angle Steel Production Line: Advanced Hydraulic Ironworker for Multiple Materials & Customization

Designed by the most advanced technology, which has the advantages of easy operation, lowconsumption and low maintenance cost. Using hydraulic transmission, it is the latest product ofdomestic multifunctional CNC angle steel punching and shearing machine. it can punch and cutangle steel, plate, square tube, round tube, various types of materials, and non standardworkpieces. Customers provide product drawings. We can customize and produce various typesof automatic punching and shearing machines to meet different needs of customers.

CNC Angle Steel Production Line Application Scenario

CNC Angle Steel Production Line Advantages

Feature 1

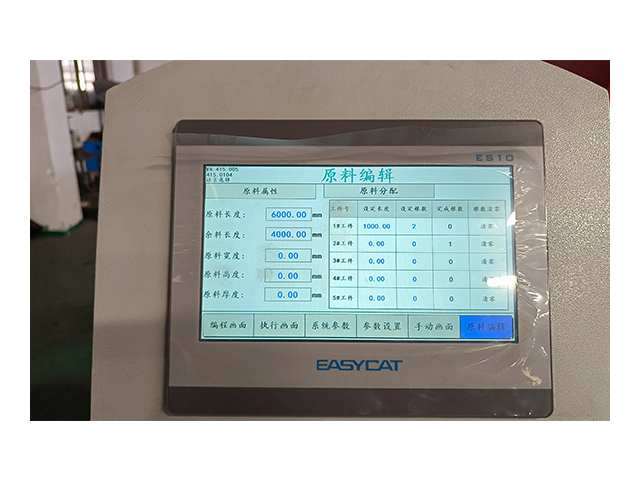

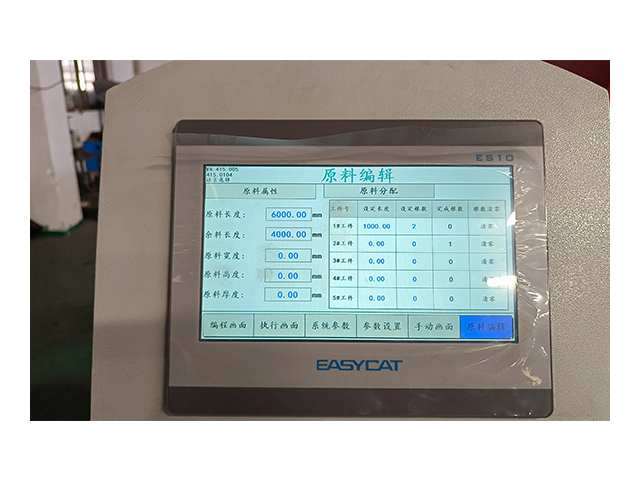

CNC controller

1. Using the human-machine interface (HMI), the operator can complete parameter setting and operation monitoring through the touch screen or computer.

2. It has intelligent navigation function, making it easy for novices to get started quickly.

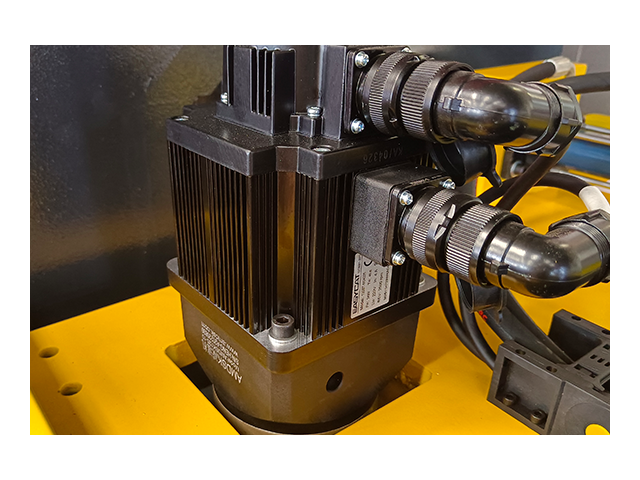

Feature 2

Angle steel production line

1. Precise positioning: Equipped with high-precision servo motor and positioning system to ensure the accuracy of processing dimensions.

2. The angle steel production line integrates cutting, punching, bending, welding and other processes to automatically complete multiple operations, greatly improving production efficiency.

CNC Angle Steel Production Line Technical Parameters

Angle steel production line offers a variety of models, covering a variety of needs from small to large, the specific technical parameters range as follows:

|

Name

|

Brand

|

|

Steel

|

Nanjing Steel Works

|

|

Cylinder

|

Jiangsu Jianhu

|

|

Motor

|

Anhui shuangra

|

Pump | weike |

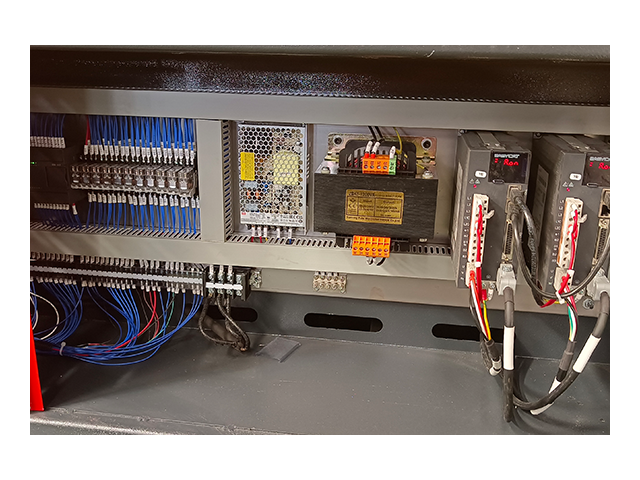

Electric | Schneider/Chint |

Electromagnetic valve | ShanghaiDAGONG |

Blade die | RONGWIN |

Sealing | Taiwan KVK |

Iimiit switch | Schneider |

AC contactor | Schneider |

Cooling system | German BRAPU |

CNC 7 inch touch screen | Easycat |

Parameters within this range reflect the wide applicability of the Angle steel production line machine in different application scenarios, from small and medium-sized precision processing to large-scale industrial manufacturing.

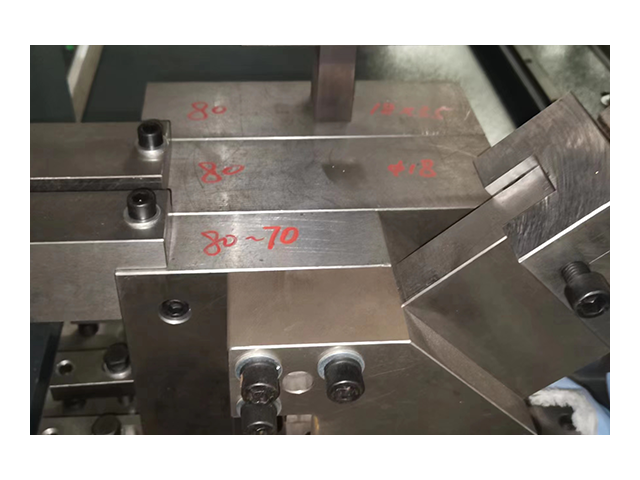

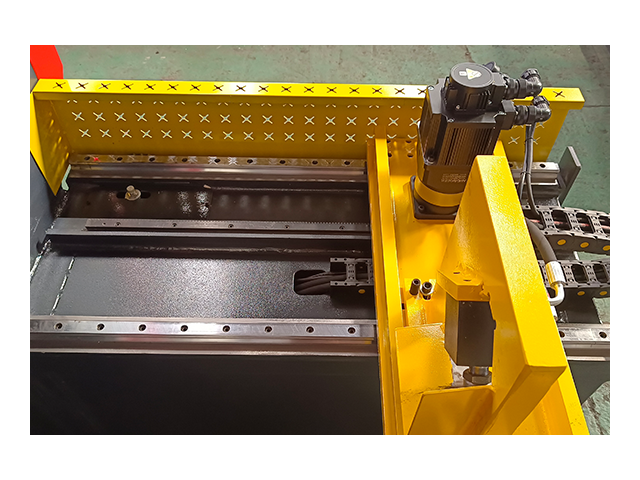

Angle Steel Production Line Machine Details Display

CNC controller

Angle steel production line

Mould position

Hinge

Main motor

Laser protection

Air cooling system

Electrical cabinet

Angle Steel Production Line Machine FAQ

What is the cutting capacity of the Angle steel production line?

The Angle steel production line guillotine shear has a cutting capacity of up to 16mm thickness and 4000mm width for various types of metal sheets.

What materials can the Angle steel production line?

The machine is designed to cut a wide range of metals, including carbon steel, stainless steel, aluminum, and other non-ferrous materials.

How is the blade clearance adjusted on the Angle steel production line?

The blade clearance is adjustable, allowing for precise cutting based on the thickness of the material being processed. This ensures clean, accurate cuts with minimal burr.

What are the key features of the Angle steel production line?

Key features include an advanced hydraulic system, a user-friendly control interface, adjustable blade clearance, and a robust construction designed for long-term durability and stable performance.