RONGWIN Customizable Hydraulic notching machine | metal sheet angle cutting

- Price

- US $14000-10000

- Model

- Hydraulic notching machine

- MOQ

- 1 piece

Item specifics

- Machine type

- Synchronized

- Degree of automation

- Fully Automatic

- Degree of oldness

- New

- Country of origin

- China

- Machinable materials

- Brass/Copper /ALLOY /Stainless Steel

- Core selling point

- Long Service Life

- Warranty

- 1 Year

- Applicable industries

- Building Material Shops

- Marketing type

- Other

- Core component warranty period

- 1 Year

Review

Description

Hydraulic Notching Machine introduction

RONGWIN Press Brake Bending Efficiency and Synchronization System

1. Suitable fdor large size sheet metal bending, reduce artificial

2. Improve press brake processing efficiency,ensure the accuracy of bending angle

3. Accurately read the displacement data of Y axis and keep 100% synchronization with Y axis

4. Independent control system, no need to upgrade the original system of the bending machine

5. Suitable for matching with various types of press brake

6. Adjust the up and down movement according to the height of the die, and the size of the V slot

Application Scenario

Advantages

Feature 1

Unique advantage

There is no need to install an additional grating ruler or a rope encoder, and the Y-axis control signal of the bending machine is directly introduced from the control cabinet to ensure 100% synchronization with the equipment, and at the same time effectively reduce the follow-up spare parts procurement costs and after-sales service costs.

Switch to other equipment flexibly, realize the most convenient "one-button switching" mode, and use the minimum cost to preset the connection port between the follower and the bending machine in advance.

Feature 2

Unique transmission structure - lever structure

The leading design of the bending industry is driven by the servo motor + reducer to drive the spur gear and the spur rack, and the adjustable lever structure connection on the top of the spur rack pushes the table to rotate around the center of the circle to realize the bending follow-up.

Using the lever structure, each joint is connected together and connected with the table, when the spur rack pushes the table, the weight of the load is evenly distributed on each joint structure through the lever connection, so that the force of the spur rack is shared, Greatly improve the service life of the entire follow-up mechanism. At the same time, it also ensures the accuracy of the entire mechanism and the smooth and efficient rotation in the process. The structure is stable and requires little daily specialized maintenance and upkeep.

Hydraulic Notching Machine Technical Parameters

Hydraulic Notching Machine offers a variety of models, covering a variety of needs from small to large, the specific technical parameters range as follows:

Model | QF28Y-4x200 | QF28Y-6x200 | QX28Y-4x200 | QX28Y-6x200 |

Max. Notching thickness-Mild steel | 4mm | 6mm | 4mm | 6mm |

|

Max. Notching thickness-Stainlesssteel

|

2mm

|

3mm |

2mm

|

3mm

|

|

Notching Length

|

200mm

|

200mm |

200mm

|

200mm

|

|

Notching angle range

|

90 degree

|

90 degree |

40-135degree

|

40-135degree

|

|

Main motor power

|

4kw

|

4kw |

5.5kw

|

5.5kw

|

Parameters within this range reflect the wide applicability of the Hydraulic Notching Machine in different application scenarios, from small and medium-sized precision processing to large-scale industrial manufacturing.

Hydraulic Notching Machine Details Display

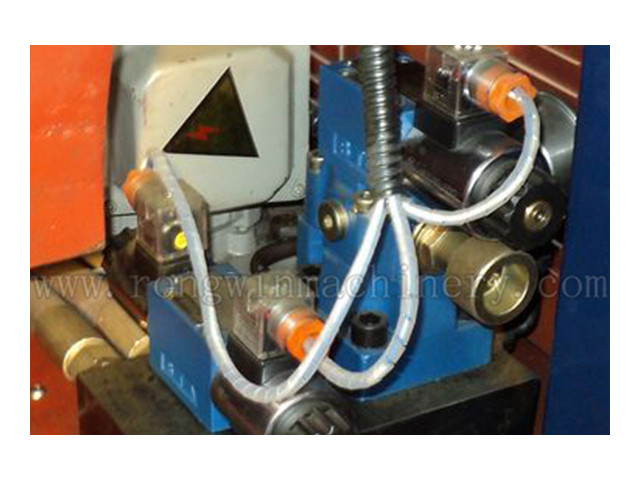

Hydraulic valve group

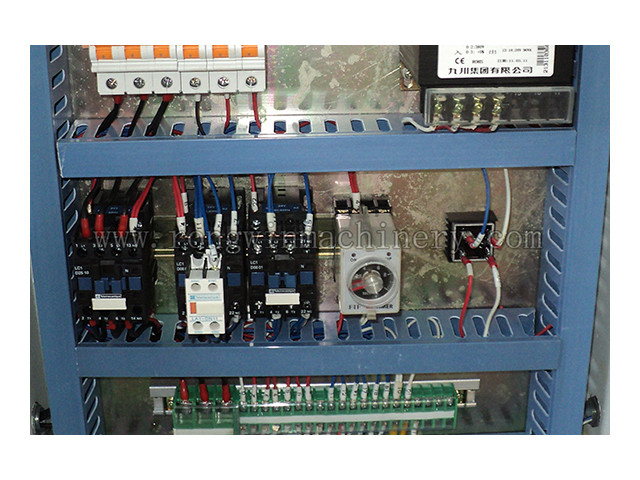

Electrical cabinet

Operation button

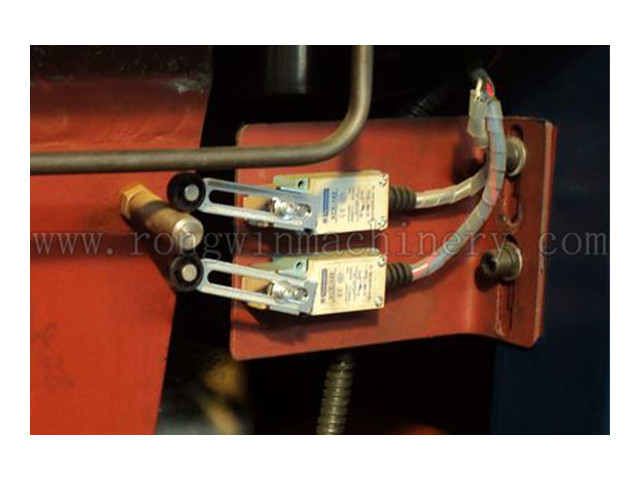

Limit switch

Hydraulic Notching Machine FAQ

How to operate QC28Y-4x200 hydraulic cutting machine?

We have our own CD/manual to show how to operate the machine. You can deepen your knowledge and understanding through the existing documents. In addition, face-to-face machine teaching through Internet video is also feasible. Because of the high-speed development of the Internet, the world has become smaller, and you can contact us for help at any time.

What does maintenance and repair of hydraulic cutting machines include?

Before starting the machine, remove foreign objects and metal fragments, and check whether the electrical switches, cables and fasteners are normal and loose. Before performing machine maintenance or wiping the machine, the tool mold should be lowered and the power should be turned off.

Hydraulic oil circuit: Check the oil level in the oil tank every week, and if the hydraulic system is repaired, it should also be checked. Under normal working conditions, the oil level surface should be kept at 2/3 of the dipstick and should not be lower than the red line of the dipstick.

What are the operating steps of a hydraulic cutting machine?

Turn on the machine: turn on the main power switch, turn on the emergency stop button, start the oil pump, select the switch (inching and single), adjust the scale according to the cutting angle and lock it, place the workpiece, and step on the foot switch to cut.

Test the machine: Test drive before cutting the angle to ensure that the white steel knife can move up and down normally, otherwise it will cause damage to the tool and machine. Then run it continuously for 1-2 times, and start working after confirming that there is no abnormal noise.

Gear position confirmation and adjustment: Check whether the gear position is adjusted to the specified position before cutting the angle.

Cutting angle: Remove burrs on the edge of the plate before cutting, close the gear surface when cutting, and the remaining material will fall into the remaining material box at the rear of the machine after cutting is completed (it must be cleaned regularly).

Turn off: Press and hold the foot switch, press the emergency stop button, and turn off the main power.

What are the maintenance tips for hydraulic cutting machines?

Maintenance is more than just a routine, it's an investment in efficiency, safety and overall business success. By prioritizing regular inspections, lubrication and timely repairs, you can maximize the benefits of your hydraulic cutter while minimizing risk and cost.

Advanced maintenance techniques include vibration analysis, thermal imaging, precision calibration, component balancing, lubrication optimization and predictive maintenance.