V Grooving Groover Cutting Machine | For high-precision machining of materials

- Price

- US $8900-7900

- Model

- RWGT01 gantry type v grooving machine

- MOQ

- 1 piece

Item specifics

- Marketing Type

- New Product 2024

- Place of Origin

- AanHui, China

- Weight (KG)

- 6200

- Core Components

- Motor, Gear, Pump

- Power (kW)

- 5

- Warranty

- 1years

- Key Selling Points

- Automatic

- Voltage

- 380v

- V groove cutter

- Cnc V-cutting Machine

Review

Description

V Grooving Groover Cutting Machine Introduction

RongWIn Hot Selling Stainless Steel V Grooving Machine With Low Prlce

Our machine use structure design,Overall rigidity, small deformation.

This machine beam is fixed , has feeding system,worktable levelness is within +0.03mm.

Blade rack move right and left by synchronous belt, V-cutting process is very stable,and thecutting surface is smooth.

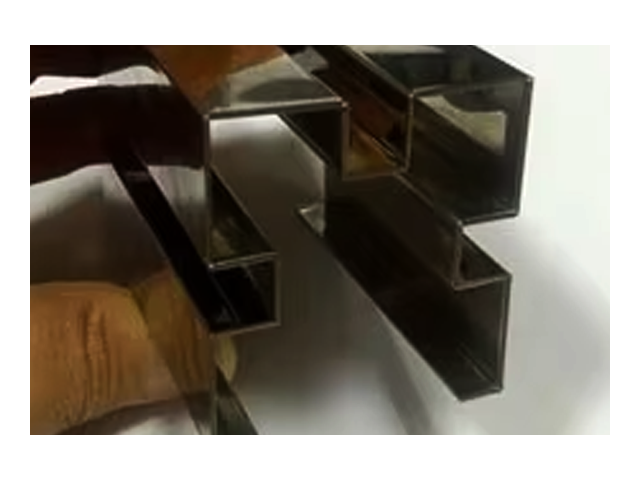

V Grooving Groover Cutting Machine Application Scenario

V Grooving Groover Cutting Machine Advantages

Feature 1

Metal plate

1. Unlike conventional machines that move the sheet metal, this machine fixes it in place, preventing scratches and ensuring high-speed processing, especially for mirror-finish stainless steel plates.

Feature 2

Laser safety protection

1. DSP Laser safety device protects the press brake operator from the danger of crushing between the moving and fixed part of the

2. DSP Laser safety device is mounted on the moving part of the machine, and the protection zone moves with the part. When an obstacle is detected, such as an operators fingers, detection is immediate and the machine can be stopped.

V Grooving Groover Cutting Machine Technical Parameters

V Grooving Machine offers a variety of models, covering a variety of needs from small to large, the specific technical parameters range as follows:

|

Gantry Type CNC Grooving Machine

|

Max Grooving Width (mm) |

Max Grooving Length (mm) |

Grooving Thickness (mm) |

Grooving Thickness (mm) |

Grooving Speed (mm) | X axis Min Settiing Value (mm) | X axis Positioning Accuracy (mm) | Y axis Min Settiing Value (mm) | Y axis Positioning Accuracy (mm) | Z axis Min Settiing Value (mm) | Z axis Positioning Accuracy (mm) | Main Motor Power (kw) | Dimensions(L×W×H) | Weight (kg) |

|

1250×3200

|

1250

|

3200

|

0.4-6 |

5-70

|

0.01 | ±0.05 | 0.01 | ±0.05 | 0.01 | ±0.03 | ±0.03 | 5.5 | 5200×2300×1680 | 7200 |

|

1250×4000

|

1250

|

4000

|

0.4-6 |

5-70

|

0.01 | ±0.05 | 0.01 | ±0.05 | 0.01 | ±0.03 | ±0.03 | 5.5 | 5200×2300×1680 | 8100 |

|

1500×3200

|

1500

|

3200

|

0.4-6 |

5-70

|

0.01 | ±0.05 | 0.01 | ±0.05 | 0.01 | ±0.03 | ±0.03 | 5.5 | 5200×2300×1680 | 8000 |

1500×4000 | 1500 | 4000 | 0.4-6 | 5-70 | 0.01 | ±0.05 | 0.01 | ±0.05 | 0.01 | ±0.03 | ±0.03 | 5.5 | 5200×2300×1680 | 9000 |

Parameters within this range reflect the wide applicability of the V Grooving Machine in different application scenarios, from small and medium-sized precision processing to large-scale industrial manufacturing.

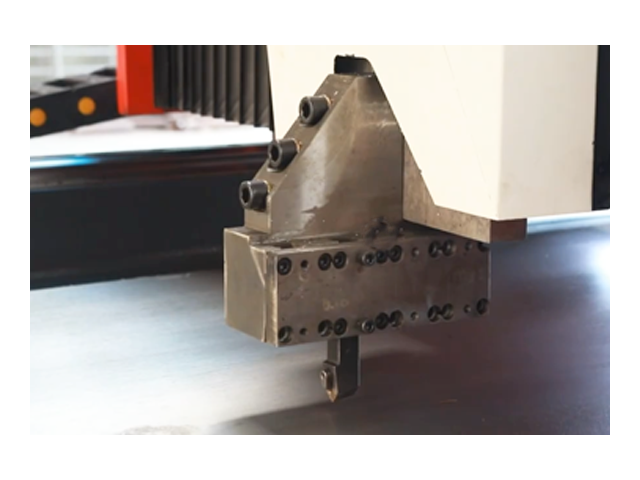

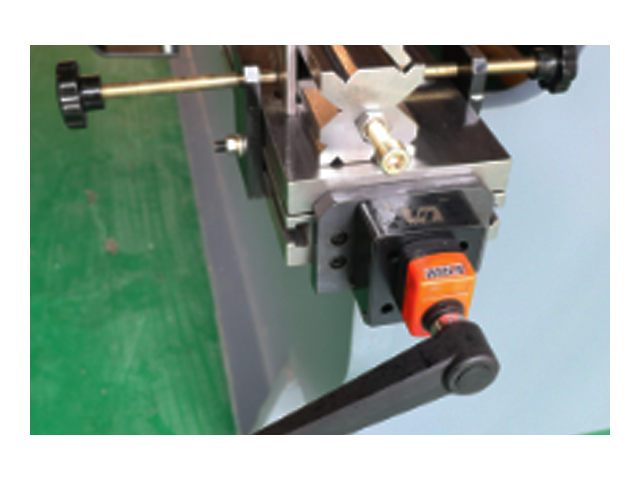

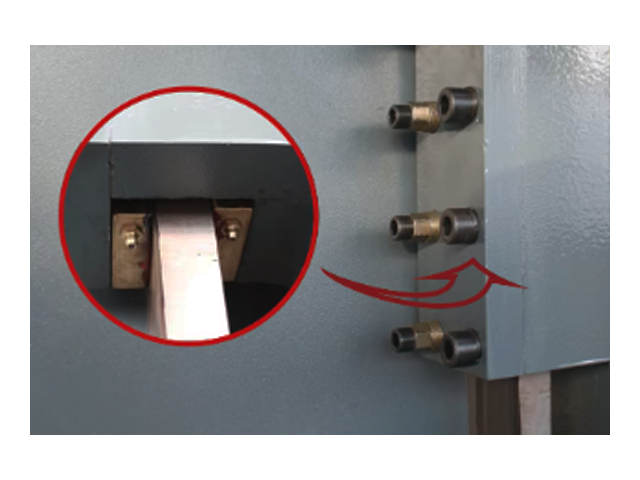

V Grooving Groover Cutting Machine Details Display

Stopper

Main motor

Quick release clamping

Pipe joint

Schneider electric

Laser safety protection

Manual compensation

Guide

V Grooving Groover Cutting Machine FAQ

Can you supply the relevant documentation?

Yes, we can provide most documentation including Certificates of Analysis/Conformance; Insurance; Origin, and other export documents where required.

What is the average lead time?

For samples, the lead time is about 7 days.

For mass production, the lead time is 20-30 days after receiving the deposit payment.

The lead times become effective when (1) we have received your deposit, and (2) we have your final approval for your products.

If our lead times do not work with your deadline, please go over your requirements with your sale. In all cases we will try to

accommodate your needs. In most cases we are able to do so.

What kinds of payment methods do you accept?

You can make the payment to our bank account, Western Union or PayPal:30% deposit in advance, 70% balance against the copy of B/L.Or irrevocable LC at sight.

Do you guarantee safe and secure delivery of products?

Yes, we always use high quality export packaging.

We also use specialized hazard packing for dangerous goods and validated cold storage shippers for temperature sensitive items.

Specialist packaging and non-standard packing requirements may incur an additional charge.