RONGWIN Customizable Swing Beam Shearing Machine | Metal Cutting

- Price

- US $9000-8000

- Model

- Swing Beam Shearing Machine

- MOQ

- 1 piece

Item specifics

- country of origin

- China

- state

- New

- Equipment Classification

- Shearing Machines

- Video factory inspection

- Provided

- Mechanical test report

- Provided

- Marketing Type

- Hot Product 2024

- Core component warranty period

- 1 Year

- Core Components

- PLC Engine Bearing

- Warranty

- 1 Year

- Core selling point

- High-accuracy

Review

Description

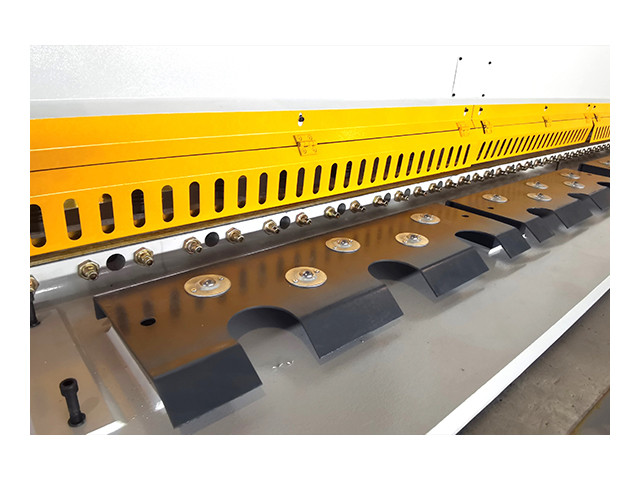

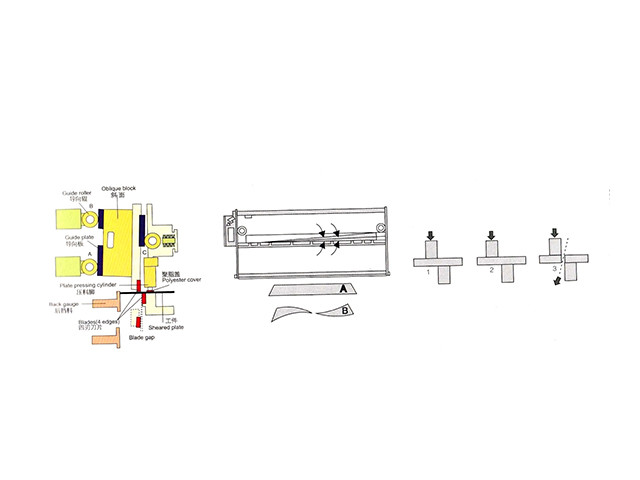

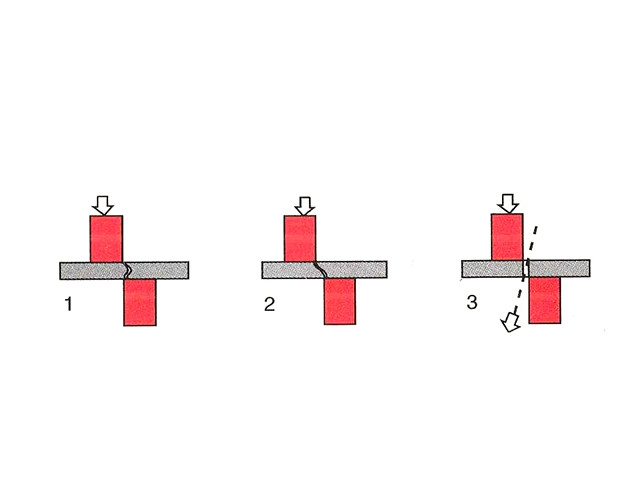

The QC12Y/K is a hydraulic swing beam shear designed for high-efficiency metal sheet cutting. It is equipped with advanced features to ensure precision and durability. Key attributes include:Hydraulic Drive System: Provides stable and powerful cutting capabilities, ideal for a wide range of metal materials.Adjustable Blade Clearance: Allows for precise adjustments to ensure smooth, accurate cuts, improving overall cutting quality.User-Friendly Control: Can be equipped with either NC (Numerical Control) or CNC (Computer Numerical Control) systems for easy operation and enhanced functionality.Robust Construction: Built with high-strength materials for long-term durability and reliable performance.High Precision: Advanced mechanical and hydraulic design ensures consistent and accurate cuts.

Type | Cutting thickness(mm) | Cutting width

(mm) | Cutting angle(º) | Material strength

(KN/cm) | Stopper adjust range(mm) | Travel times

(/min) | Power (kw) | Dimension LxWxH (mm) |

4x2500 | 4 | 2500 | 1º30’ | ≦450 | 20~500 | 14 | 5.5 | 3040x1550x1550 |

4x3200 | 4 | 3200 | 1º30’ | ≦450 | 20~500 | 12 | 5.5 | 3840x1550x1550 |

4x4000 | 4 | 4000 | 1º30’ | ≦450 | 20~600 | 10 | 5.5 | 4600x1700x1700 |

|

4x6000

|

4

|

6000

|

1º30’ | ≦450 |

20~800

|

5 | 7.5 | 6460x2100x2200 |

|

6x2500

|

6

|

2500 |

1º30’ | ≦450 |

20~500

|

14 | 7.5 | 3040x1710x1620 |

|

6x3200

|

6

|

3200

|

1º30’ | ≦450 |

20~500

|

12 | 7.5 | 3840x1710x1620 |

6x4000 | 6 | 4000 | 1º30’ | ≦450 | 20~600 | 9 | 7.5 | 4620x1850x1700 |

|

6x5000

|

6

|

5000

|

1º30’ | ≦450 |

20~600

|

8 | 7.5 | 3140x1710x1620 |

6x6000 | 6 | 6000 | 1º30’ | ≦450 | 20~800 | 5 | 11 | 6480x2100x2300 |

8x2500 | 8 | 2500 | 1º30’ | ≦450 | 20~500 | 11 | 7.5 | 3040x1700x1700 |

8x3200 | 8 | 3200 | 1º30’ | ≦450 | 20~500 | 8 | 7.5 | 3860x1700x1700 |

8x4000 | 8 | 4000 | 1º30’ | ≦450 | 20~600 | 8 | 7.5 | 4640x1700x1700 |

8x5000 | 8 | 5000 | 1º30’ | ≦450 | 20~600 | 8 | 7.5 | 5400x2400x2000 |

8x6000 | 8 | 6000 | 1º30’ | ≦450 | 20~800 | 8 | 11 | 6480x2100x2350 |

10x2500 | 10 | 2500 | 1º30’ | ≦450 | 20~500 | 10 | 11 | 3040x1800x1700 |

10x3200 | 10 | 3200 | 1º30’ | ≦450 | 20~500 | 10 | 11 | 3860x2000x1700 |

10x4000 | 10 | 4000 | 1º30’ | ≦450 | 20~600 | 10 | 11 | 4650x2100x2000 |

10x6000 | 10 | 6000 | 1º30’ | ≦450 | 20~800 | 10 | 15 | 6500x2100x2300 |

12x2500 | 12 | 2500 | 2º | ≦450 | 20~600 | 12 | 18.5 | 3140x2050x2000 |

12x3200 | 12 | 3200 | 2º | ≦450 | 20~600 | 10 | 18.5 | 3880x2150x2000 |

12x4000 | 12 | 4000 | 2º | ≦450 | 20~600 | 10 | 18.5 | 4680x2150x2100 |

12x5000 | 12 | 5000 | 2º | ≦450 | 20~600 | 6 | 18.5 | 3240x1900x1900 |

12x6000 | 12 | 6000 | 2º | ≦450 | 20~1000 | 5 | 18.5 | 6900x2600x2700 |

16x2500 | 16 | 2500 | 2º30’ | ≦450 | 20~600 | 10 | 18.5 | 3140x2150x2000 |

16x3200 | 16 | 3200 | 2º30 | ≦450 | 20~600 | 10 | 18.5 | 3880x2150x2000 |

16x4000 | 16 | 4000 | 2º30’ | ≦450 | 20~800 | 10 | 18.5 | 4650x2150x2200 |

16x5000 | 16 | 5000 | 2º | ≦450 | 20~1000 | 6 | 18.5 | 5900x2600x2700 |

16x6000 | 16 | 6000 | 2º | ≦450 | 20~1000 | 5 | 22 | 6900x2700x2700 |

20x2500 | 20 | 2500 | 3º | ≦450 | 20~800 | 8 | 22 | 3440x2300x2500 |

20x3200 | 20 | 3200 | 3º | ≦450 | 20~800 | 8 | 22 | 4150x2350x2700 |

20x4000 | 20 | 4000 | 3º | ≦450 | 20~1000 | 5 | 22 | 4850x2600x2400 |

20x6000 | 20 | 6000 | 3º | ≦450 | 20~1000 | 4 | 22 | 6700x3000x3000 |