RONGWIN Customizable Guillotine Shearing Machine | Home Farm Metal Cutting

- Price

- US $9000-8000

- Model

- Guillotine Shearing Machine

- MOQ

- 1 piece

Item specifics

- Color

- Customizable

- Country of origin

- China

- State

- New

- Equipment classification

- Shearing Machines

- Video factory inspection

- Provided

- Mechanical test report

- Provided

- Marketing type

- Hot Product 2024

- Core component warranty period

- 1 Year

- Core components

- PLC Engine Gearbox Bearing

- Warranty

- 1 Year

Review

Description

Guillotine Shearing Machine introduction

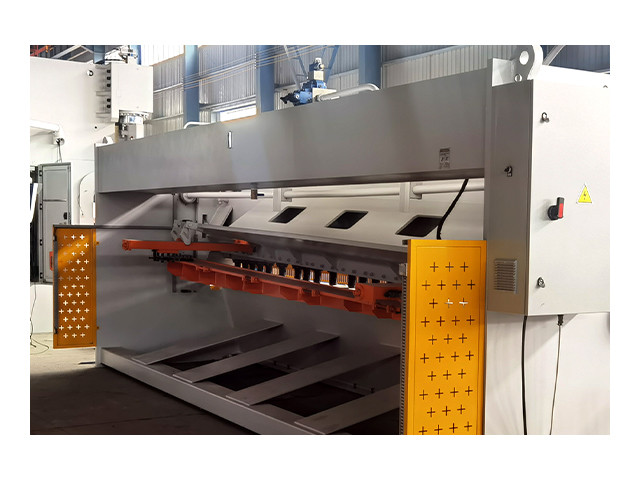

QC11Y/K Hydraulic Guillotine Shear: High-Efficiency Metal Cutting for Precision and Durability

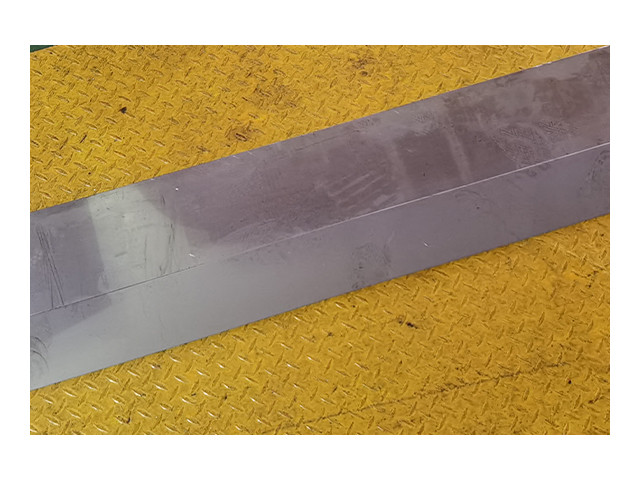

QC11Y/K Hydraulic Guillotine Shear is a high-efficiency cutting machine designed for precise and clean cuts on metal sheets. With a cutting capacity of up to 16mm thickness and 4000mm width, it is ideal for industries like manufacturing, automotive, and construction. Featuring an advanced hydraulic system, adjustable blade clearance, and a user-friendly control interface, it ensures smooth operation, high precision, and low maintenance. The robust construction guarantees long-term durability and stable performance

Guillotine Shearing Machine Application Scenario

Guillotine Shearing Machine Advantages

Feature 1

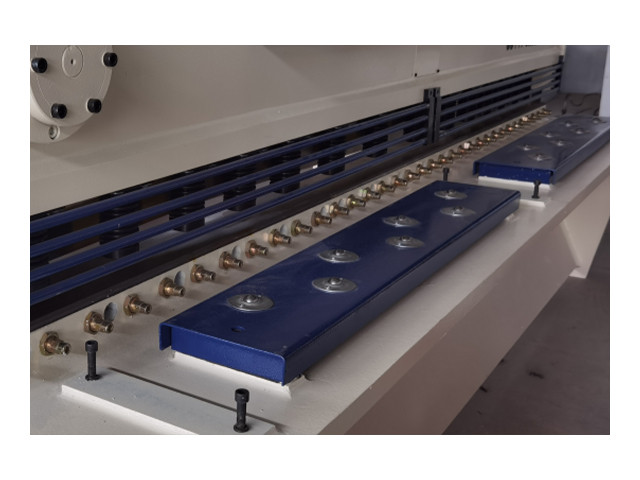

Backgauge

1. Backgauge use ball screw to improve accuracy.

2. Backgauge driven by motor with digital display.

3. Our machine add frequency inverter, X axis can one time positioning, if do not add this part, X axis cannot one time positioning.

Feature 2

E21S NC controller

1. Backgauge control

2. Control for general AC motors, frequency inverter

3. Intelligent positioning

4. Double programmable digital output

5. Stock counter

6. Program memory of up to 40 programsup to 25 steps per program

7. One side positioning

8. Retract function

9. One key backup /restore of parameters

10. mm /Inch

11. Chinese /English

Guillotine Shearing Machine Technical Parameters

Guillotine Shearing Machine offers a variety of models, covering a variety of needs from small to large, the specific technical parameters range as follows:

Type | Cutting thickness

(mm) | Cutting width

(mm) | Travel

times

(times/min) | Bumper distance

(mm) | Cutting

angel

(º) | Throat

depth

(mm) | Power

(kw) | Dimension

LxWxH (mm) |

4x2500 | 4 | 2500 | >=18 | 600 | 0.5-2 | 100 | 5.5 | 3130x1500x2070 |

4x3200 | 4 | 3200 | >=16 | 600 | 0.5-2 | 100 | 7.5 | 3830x1500x2070 |

4x4000 | 4 | 4000 | >=12 | 600 | 0.5-2 | 100 | 7.5 | 4630x1500x2070 |

|

6x2500

|

6

|

2500

|

>=15 | 600 |

0.5-2

|

100 | 7.5 | 3150x1600x2170 |

|

6x3200

|

6

|

3200

|

>=13 | 600 |

0.5-2

|

100 | 7.5 | 3850x1600x2170 |

|

6x4000

|

6

|

4000

|

>=10 | 600 |

0.5-2

|

100 | 7.5 | 4650x1600x2170 |

6x5000 | 6 | 5000 | >=8 | 600 | 0.5-2.5 | 100 | 11 | 5650x1600x2270 |

|

6x6000

|

6

|

6000

|

>=6 | 600 |

0.5-2.5

|

100 | 11 | 6650x1610x2380 |

8x2500 | 8 | 2500 | >=14 | 600 | 0.5-2 | 100 | 11 | 2170x1600x2170 |

8x3200 | 8 | 3200 | >=12 | 600 | 0.5-2 | 100 | 11 | 3870x1600x2170 |

8x4000 | 8 | 4000 | >=10 | 600 | 0.5-2 | 100 | 11 | 4670x1600x2170 |

8x5000 | 8 | 5000 | >=8 | 600 | 0.5-2.5 | 100 | 11 | 5670x1600x2270 |

8x6000 | 8 | 6000 | >=6 | 600 | 0.5-2.5 | 100 | 15 | 6670x1610x2380 |

10x2500 | 10 | 2500 | >=12 | 600 | 0.5-2 | 100 | 11 | 3190x1600x2170 |

10x3200 | 10 | 3200 | >=10 | 600 | 0.5-2 | 100 | 11 | 3890x1600x2170 |

10x4000 | 10 | 4000 | >=8 | 600 | 0.5-2 | 100 | 11 | 4690x1600x2170 |

10x5000 | 10 | 5000 | >=6 | 600 | 0.5-2.5 | 100 | 11 | 5690x1600x2270 |

10x6000 | 10 | 6000 | >=4 | 600 | 0.5-2.5 | 100 | 15 | 6690x1610x2380 |

12x2500 | 12 | 2500 | >=10 | 800 | 0.5-2.5 | 100 | 15 | 3270x1850x2315 |

12x3200 | 12 | 3200 | >=8 | 800 | 0.5-2.5 | 100 | 15 | 3970x1850x2315 |

12x4000 | 12 | 4000 | >=6 | 800 | 0.5-2.5 | 100 | 18.5 | 4770x1850x2315 |

12x5000 | 12 | 5000 | >=6 | 800 | 0.5-2.5 | 100 | 18.5 | 5770x1950x2515 |

12x6000 | 12 | 6000 | >=4 | 800 | 0.5-2.5 | 100 | 22 | 6770x2100x2750 |

16x2500 | 16 | 2500 | >=8 | 800 | 0.5-2.5 | 100 | 18.5 | 3270x1850x2315 |

16x3200 | 16 | 3200 | >=7 | 800 | 0.5-2.5 | 100 | 18.5 | 3970x1850x2315 |

16x4000 | 16 | 4000 | >=6 | 800 | 0.5-2.5 | 100 | 22 | 4770x1850x2315 |

16x5000 | 16 | 5000 | >=5 | 800 | 0.5-2.5 | 100 | 22 | 5770x1950x2515 |

16x6000 | 16 | 6000 | >=4 | 800 | 0.5-2.5 | 100 | 30 | 6770x2100x2750 |

20x2500 | 20 | 2500 | >=7 | 800 | 0.5-2.5 | 100 | 30 | 3370x2015x2575 |

20x3200 | 20 | 3200 | >=6 | 800 | 0.5-2.5 | 100 | 30 | 4070x2015x2575 |

20x4000 | 20 | 4000 | >=5 | 800 | 0.5-2.5 | 100 | 37 | 4870x2015x2675 |

20x5000 | 20 | 5000 | >=4 | 800 | 0.5-2.5 | 100 | 37 | 5870x2115x2875 |

20x6000 | 20 | 6000 | >=3 | 800 | 0.5-2.5 | 100 | 45 | 6870x2300x3200 |

25x2500 | 25 | 2500 | >=6 | 1000 | 0.5-3 | 120 | 37 | 3390x2200x2700 |

25x3200 | 25 | 3200 | >=5 | 1000 | 0.5-3 | 120 | 37 | 4090x2200x2700 |

25x4000 | 25 | 4000 | >=4 | 1000 | 0.5-3 | 120 | 45 | 4890x2350x3000 |

32x2500 | 32 | 2500 | >=5 | 1000 | 0.5-3 | 120 | 45 | 3490x2440x2915 |

32x3200 | 32 | 3200 | >=4 | 1000 | 0.5-3 | 120 | 45 | 4190x2440x3015 |

32x4000 | 32 | 4000 | >=3 | 1000 | 0.5-3 | 120 | 55 | 5100x2500x3315 |

40x2500 | 40 | 2500 | >=4 | 1000 | 0.5-3 | 120 | 75 | 3530x2500x3300 |

40x3200 | 40 | 3200 | >=3 | 1000 | 0.5-3 | 120 | 75 | 4230x2500x3500 |

Parameters within this range reflect the wide applicability of the Guillotine Shearing Machine in different application scenarios, from small and medium-sized precision processing to large-scale industrial manufacturing.

Guillotine Shearing Machine Details Display

Hydraulic valve group

Main motor

Front support

Clip sets joints

Schneider electric

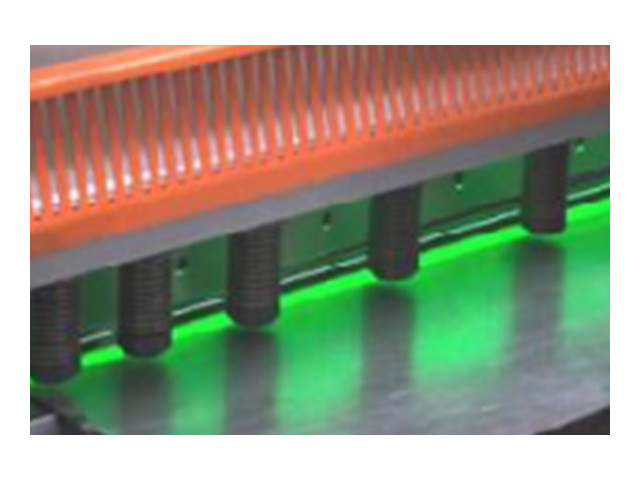

Light alignment

Frequency inverter

Backgauge

Guillotine Shearing Machine FAQ

What is the cutting capacity of the QC11Y/K shear?

The QC11Y/K hydraulic guillotine shear has a cutting capacity of up to 16mm thickness and 4000mm width for various types of metal sheets.

What materials can the QC11Y/K shear cut?

The machine is designed to cut a wide range of metals, including carbon steel, stainless steel, aluminum, and other non-ferrous materials.

How is the blade clearance adjusted on the QC11Y/K shear?

The blade clearance is adjustable, allowing for precise cutting based on the thickness of the material being processed. This ensures clean, accurate cuts with minimal burr.

What are the key features of the QC11Y/K shear?

Key features include an advanced hydraulic system, a user-friendly control interface, adjustable blade clearance, and a robust construction designed for long-term durability and stable performance.