WF67K‑E Hybrid Electro‑Hydraulic CNC Press Brake: Precision Meets Efficiency

- Share

- publisher

- Daisy Li

- Issue Time

- Jul 29,2025

Summary

The WF67K-E series CNC press brake is a precision sheet metal bending machine engineered for high efficiency, accuracy, and durability. It combines advanced torsion bar synchronization, E21 NC or upgraded CNC controllers, and hydraulic drive systems to provide consistent and repeatable bending performance for various materials and part shapes.

WF67K‑E Hybrid Electro‑Hydraulic CNC Press Brake: Precision Meets Efficiency

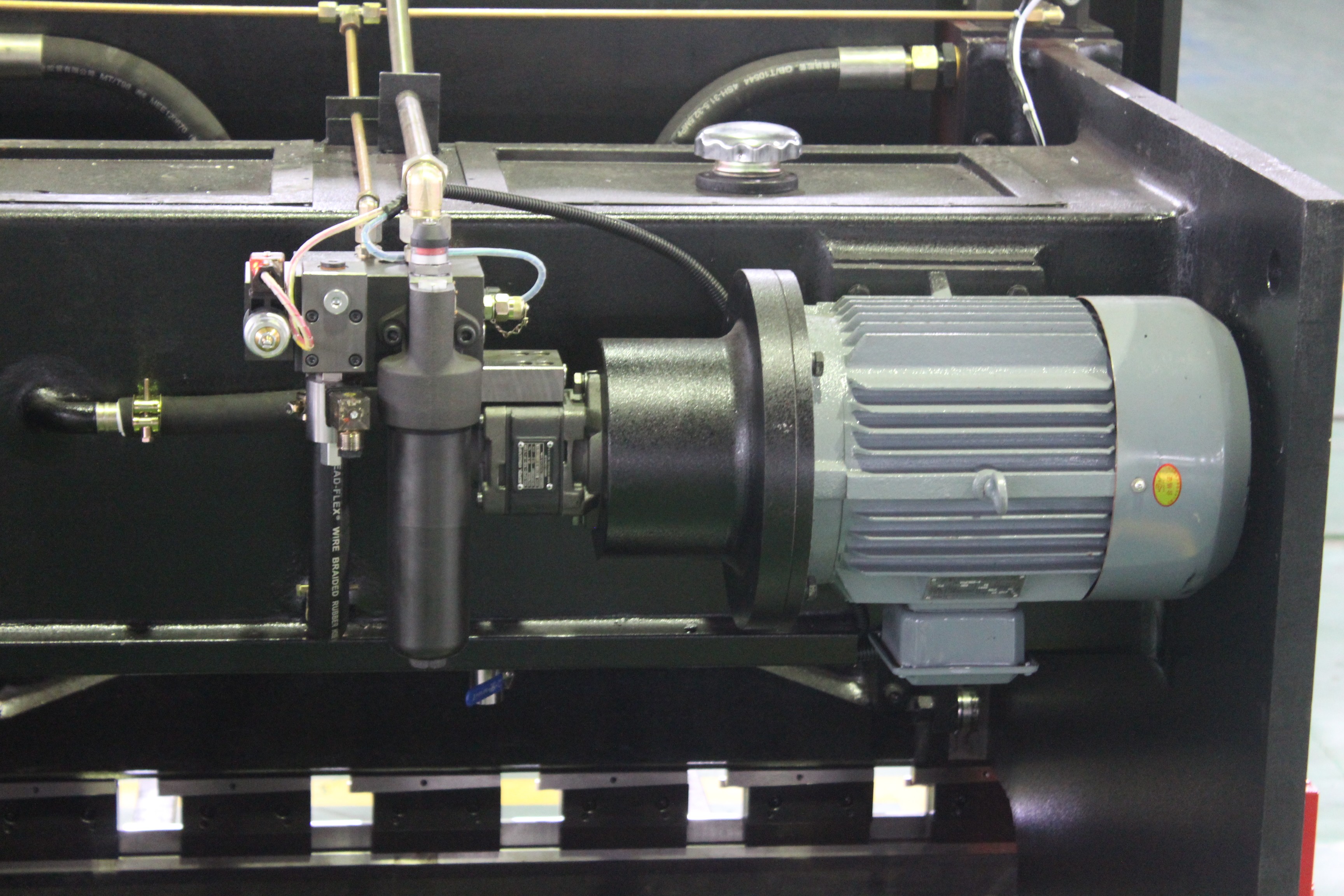

The WF67K‑E series from Rongwin Machinery is a compact, single-phase electro‑hydraulic servo CNC press brake tailored for small to mid‑size sheet metal fabrication. It offers programmable bending, high repeatability, and energy-saving servo pump control—perfectly balancing precision and cost-efficiency.

What Makes WF67K‑E Unique?

On-demand servo pump oil supply reduces energy waste by over 30%

Low heat and extended hydraulic life with longer oil change intervals

Closed-loop accuracy via German servo valves and grating ruler feedback for high positioning repeatability

Precision & Performance in Fabrication

Accurate Sliders & Repeatable Angles

WF67K‑E’s synchronized double‑cylinder design, combined with German‑made servo valves and dual‑side grating encoder feedback, ensures the slider maintains precise repeatable position—even under high-duty production. Ideal for aluminum, stainless steel and carbon steel sheet bending.

Energy-Saving & Ease of Use

Servo oil pump only operates during bending—standby zero energy consumption

Stable machine temperature, smaller oil tank, lower maintenance costs

User-friendly: input thickness, material tensile strength, width, and bending angle; machine auto-calculates pressure and stroke

Specifications & Configurations

Available tonnage: 30T–63T, bending lengths: 1600–2500 mm

Standard at 220V/380V/415V/440V single-phase power options

Back gauge driven by servo motor + ball screw, with mechanical torsion compensation

Controller options: DELEM DA69T / CT8 / CT12 axis control systems

Ideal Industries & Applications

Designed for:

Light metalworking and fabrication shops

Kitchen cabinets, telecom enclosures, elevator panels

Small-batch aerospace or automotive component bending

Why Choose WF67K‑E from Rongwin?

Combines compact footprint with high accuracy and easy operation. Excellent for shops requiring efficient performance without large investment.

| ▶️ Discover WF67K‑E Press Brake on Rongwin’s Website:Rongwin WF67K‑E Series |

Conclusion

The WF67K‑E brings together precise electro‑hydraulic control, closed‑loop feedback accuracy, and energy-efficient servo operation in a cost-conscious framework. It’s an intelligent solution for small to medium bending needs, particularly in aluminum and stainless steel fabrication. Rongwin delivers quality, affordability, and performance in one compact machine.