How to Choose the Right Bending Machine for Your Business

- Share

- Issue Time

- Aug 5,2024

Summary

Get essential tips and expert advice for choosing the perfect press brake for your business. Discover how MeteWorkMaster can help you make an informed decision.

In the highly competitive metalworking industry, choosing the right press brake is critical to your business. Press brakes are essential tools for accurately bending sheet metal, and finding the right press brake can significantly impact your productivity and the quality of your work. At MeteWorkMaster, we understand the complexities of making this decision and we will guide you through the entire process.

Learn About Bending Machines

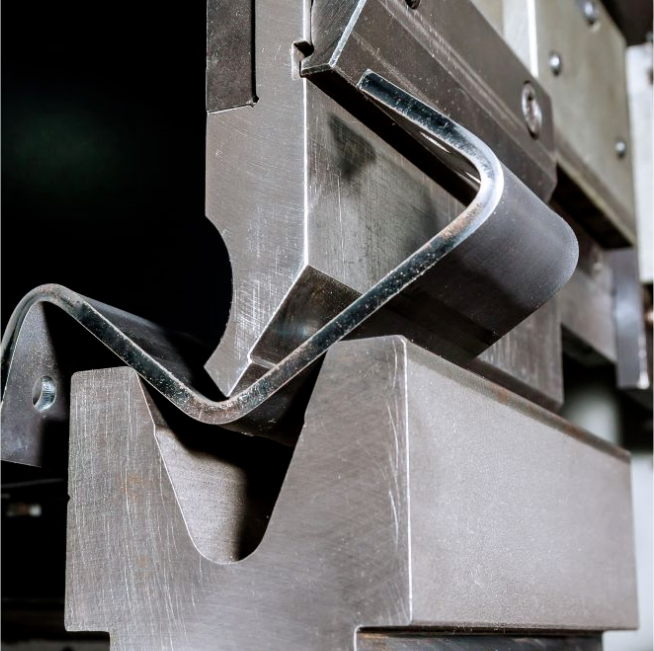

A press brake is a precision machine used to bend metal or other sheets into precise angles and shapes. It operates by clamping the workpiece between a set of punches and dies. The upper component (called the punch) lowers and applies force to the material, forcing it into the lower component (the die), which takes the desired curved shape.

This process creates predetermined bends or angles in the metal sheet. Press brakes come in a variety of sizes and configurations, from small manual machines to large computer-controlled models, making them versatile tools in metal processing and manufacturing. Their ability to produce consistent and accurate bends makes them an indispensable tool for manufacturing parts in many industries, from automotive to aerospace.

Types of Bending Machines

There are many types of press brakes, each with its own advantages and uses:

- Mechanical bending machine: Mechanical bending machine is known for its speed and precision. They use a flywheel driven by an electric motor to engage the punch.

- Hydraulic press brake: These machines use hydraulic cylinders to move the punch. They are known for their sustained force and are suitable for heavy-duty applications.

- Electric press brakes: Powered by electric motors, they are known for their high energy efficiency and low maintenance requirements.

- Pneumatic press brake: Uses air pressure to move the punch, usually used for lighter applications.

Key Factors to Consider When Choosing a Bending Machine

When choosing the right press brake for your business, there are several key factors that must be evaluated to ensure the machine meets your needs and operational requirements:

Bending Force and Load Carrying Capacity

Bending force, usually measured in tons, is one of the most critical factors to consider. This parameter determines the maximum thickness and length of material that the press brake can effectively handle. For example, if you frequently work with thick materials, you will need a press brake with greater bending power. At MeteWorkMaster, we recommend evaluating your typical workload and selecting a press brake that not only meets your current needs, but also has some additional capabilities to accommodate future needs or unexpected tasks.

Bending Machine Length

The length of the press brake (often called the bed length) is another important aspect. The machine's bed length should be long enough to accommodate the longest piece of metal you plan to bend. It is important to measure the maximum length of the material and consider leaving a safety margin to ensure flexibility and prevent any potential problems during the bending process. A press brake with a sufficient bed length helps handle larger workpieces more efficiently.

Precision and Accuracy

Precision and accuracy are critical to producing high-quality bent parts. Machines with advanced control systems and features are critical to achieving repeatable accuracy. Look for press brakes equipped with modern technology, such as CNC controls, advanced positioning systems and high-resolution encoders. At MeteWorkMaster, our press brakes feature state-of-the-art technology and are designed to consistently deliver precise and reliable results, ensuring your finished parts meet the highest quality standards.

Easy to Use and Automate

Modern press brakes have a variety of automation features that significantly increase productivity. Features such as user-friendly controls, programmable bend sequences, automatic tool changes, and advanced material handling systems simplify operations. Consider machines that offer intuitive interfaces and automated features to reduce setup time, minimize human error, and increase overall efficiency. Automation can greatly improve consistency and reduce the time spent on manual adjustments.

Security Features

Safety is a top priority when using a press brake. Make sure the machine you choose is equipped with comprehensive safety features to protect operators and maintain a safe work environment. Look for machines with light curtains, emergency stop buttons, safety guards and other protective mechanisms. At MeteWorkMaster, we prioritize safety and ensure that all of our press brakes meet strict safety standards, providing safe and reliable operation.

Other Considerations

In addition to the main factors, there are other considerations that may influence your decision:

Tool Compatibility

The type of tooling you use affects the versatility and efficiency of your press brake. Make sure the machine you choose is compatible with a variety of tooling options to meet various bending requirements.

Machine Footprint and Space Requirements

Consider the space available in your workshop. Press brakes come in a variety of sizes, and it's critical to choose one that fits your workspace and is easy to operate and maintain.

Maintenance and Support

Regular maintenance is essential to keep your press brake in top condition. Choose a manufacturer like MeteWorkMaster that offers reliable customer support, maintenance services, and readily available spare parts.

Why Choose MeteWorkMaster for Your Press Brake Needs

At MeteWorkMaster, we pride ourselves on providing high-quality press brakes that meet our customers' various needs. Here are some reasons why you should consider us for your next press brake purchase:

Rich Product Range

We offer a variety of bending machines including CNC bending machines, manual bending machines, sheet metal bending machines, hydraulic bending machines and electric bending machines. Our extensive product line ensures you can find the perfect machine for your specific application.

Customization Options

We understand that every business has unique needs. Therefore, we offer customization options to tailor our press brakes to your specific needs. From specialized tools to advanced control systems, we can customize our machines to increase your productivity.

Expert Guidance and Support

Our team of experts will guide and support you throughout the selection process. We can help you assess your needs, recommend the best press brake for your application, and provide ongoing support to ensure your machine is operating at peak performance.

Quality and Safety Commitment

Quality and safety are at the heart of everything we do. Our press brakes are manufactured to the highest standards using quality materials and advanced technology. We also prioritize safety features to protect your operators and increase productivity.

In Conclusion

Choosing the right press brake for your business is a critical decision that requires careful consideration of a variety of factors. By evaluating your bending force and capacity requirements, press brake length, precision and accuracy needs, ease of use and safety features, you can make an informed decision that will benefit your business in the long run.

MeteWorkMaster is a professional custom press brake manufacturer, and we are committed to helping you find the perfect press brake for your needs. With our extensive product line, customization options, expert guidance, and focus on quality and safety, you can trust us to provide the best solution for your metalworking application.

Contact us today to learn more about our press brakes and how we can help you increase productivity and achieve your business goals.