Fiber Laser Cutter vs. CO₂ Laser Cutter

- Share

- Issue Time

- Sep 23,2025

Summary

Explore the key differences between fiber and CO₂ laser cutters. Understand which technology suits your business needs, considering factors like material type, cutting speed, and operational costs.

Fiber Laser Cutter vs. CO₂ Laser Cutter: Which is Right for Your Business?

Laser cutting technology has revolutionized the manufacturing industry, offering precision and efficiency. Two prominent types of laser cutters are fiber laser cutters and CO₂ laser cutters. Understanding these technologies helps companies make smart investment choices. It also helps them find the industrial laser cutting machine that meets their specific needs.

Understanding the Basics of Fiber and CO₂ Laser Cutters

What is a Fiber Laser Cutter?

A fiber laser cutter uses a solid-state laser. This laser is made by a fiber optic cable that has rare-earth elements, like ytterbium. This high-speed fiber laser cutting machine is great for cutting metals.

It works well with stainless steel, aluminum, and brass and offers high precision. Fiber lasers offer faster cutting speeds, lower operational costs, and excellent energy efficiency compared to traditional laser systems.

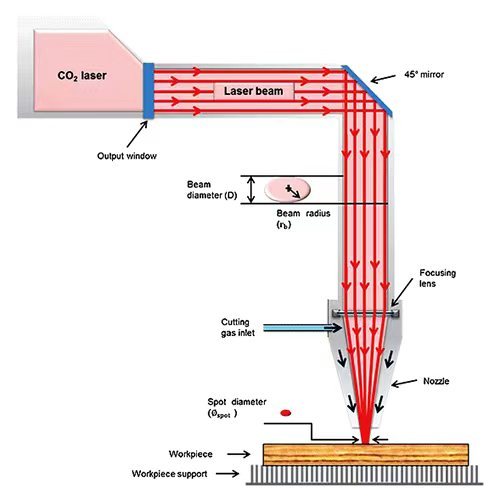

What is a CO₂ Laser Cutter?

A CO₂ laser cutter uses a gas laser. This laser usually mixes carbon dioxide, nitrogen, and helium to create a laser beam. CO₂ laser cutters are versatile, capable of cutting metals, plastics, wood, and other non-metal materials. While flexible, they may be slower than fiber laser cutters when cutting reflective metals such as aluminum.

Key Differences Between Fiber and CO₂ Laser Cutters

Cutting Speed and Precision

Fiber lasers provide superior cutting speed and precision, especially for thin metals. For example, a fiber laser can cut 1mm stainless steel up to six times faster than a CO₂ laser. This makes fiber laser cutters for metal fabrication ideal for high-volume production and time-sensitive projects.

Operational Costs and Efficiency

Fiber lasers are highly energy-efficient, require minimal maintenance, and have a longer lifespan. Investing in a fiber vs CO₂ laser cutter can reduce operational costs significantly, providing faster ROI for businesses focusing on industrial laser cutting solutions.

Material Compatibility

CO₂ lasers can cut many materials. However, fiber lasers are better for metals. This includes shiny materials like aluminum and brass.

They are perfect for all-in-one laser cutting machines. These machines can work with both plate and pipe materials. An example is the RONGWIN customizable solution.

| Features | CO₂ laser cutting machine | |

| Applicable materials | Mainly used for non-metal, can cut thin metal | Mainly used for metal cutting |

| Wavelength | 10.6μm (suitable for non-metal) | 1.06μm (suitable for metal) |

| Cutting quality | Smooth cut, suitable for fine engraving | Higher metal cutting efficiency |

Equipment cost | Relatively low | Higher price, low maintenance cost |

Energy consumption | Relatively high | More energy-efficient |

Application areas | Widely used in advertising, clothing, packaging, woodworking, etc. | Mainly used in metal processing, automobile, aviation and other industries |

Choosing the Right Laser Cutter for Your Business

When selecting a fiber laser cutter for metal fabrication, consider:

Materials: Mostly metals? Fiber lasers excel at reflective and thin metals.

Production Volume: Need high-speed cutting? Fiber lasers offer faster cycles.

Budget: Fiber lasers save operational costs over time through efficiency.

Application:

You can use an all-in-one fiber laser cutting machine for cutting both plates and pipes. The RONGWIN customizable plate & pipe laser cutter is a great option for this.

Conclusion

Choosing a fiber laser cutter or a CO₂ laser cutter depends on a few factors.

First, consider the materials you will use. Next, think about your production needs. Finally, take your budget into account.

Fiber laser cutters offer faster cutting speeds, higher precision, and lower operational costs for metal fabrication.

Investing in a good fiber laser cutting machine, like the RONGWIN all-in-one model, can improve operations. It can also boost efficiency and offer long-term returns.