Press Brake Backguage | Ultimate Trunk Protection & Organization | Official Site

- Price

- US $3000-2800

- Model

- Backguage

- MOQ

- 1 piece

Item specifics

- Main body material

- high carbon steel (S50C) / sta

- Protective coating

- hot dip galvanizing (≥50μm)/el

- Overall dimensions

- length (suitable for 2.5-4m wo

- Modularity level

- integral/split quick-release

- Repeat positioning accuracy:

- ±0.02mm/±0.05mm/±0.1m

- Maximum moving speed

- 200mm/s / 350mm/s

Review

Description

Automatic Synchronized Sheet Metal Brake Press with CNC Control New Condition Backgauge for Construction Industries

Spot supply bending machine accessories such as press brake backgauge, bending machine CNC lifting gear finger, bending machine backgauge beam, mechanical accessories rail slider,synchronous wheel and synchronous belt and so on.

Detailed lmages

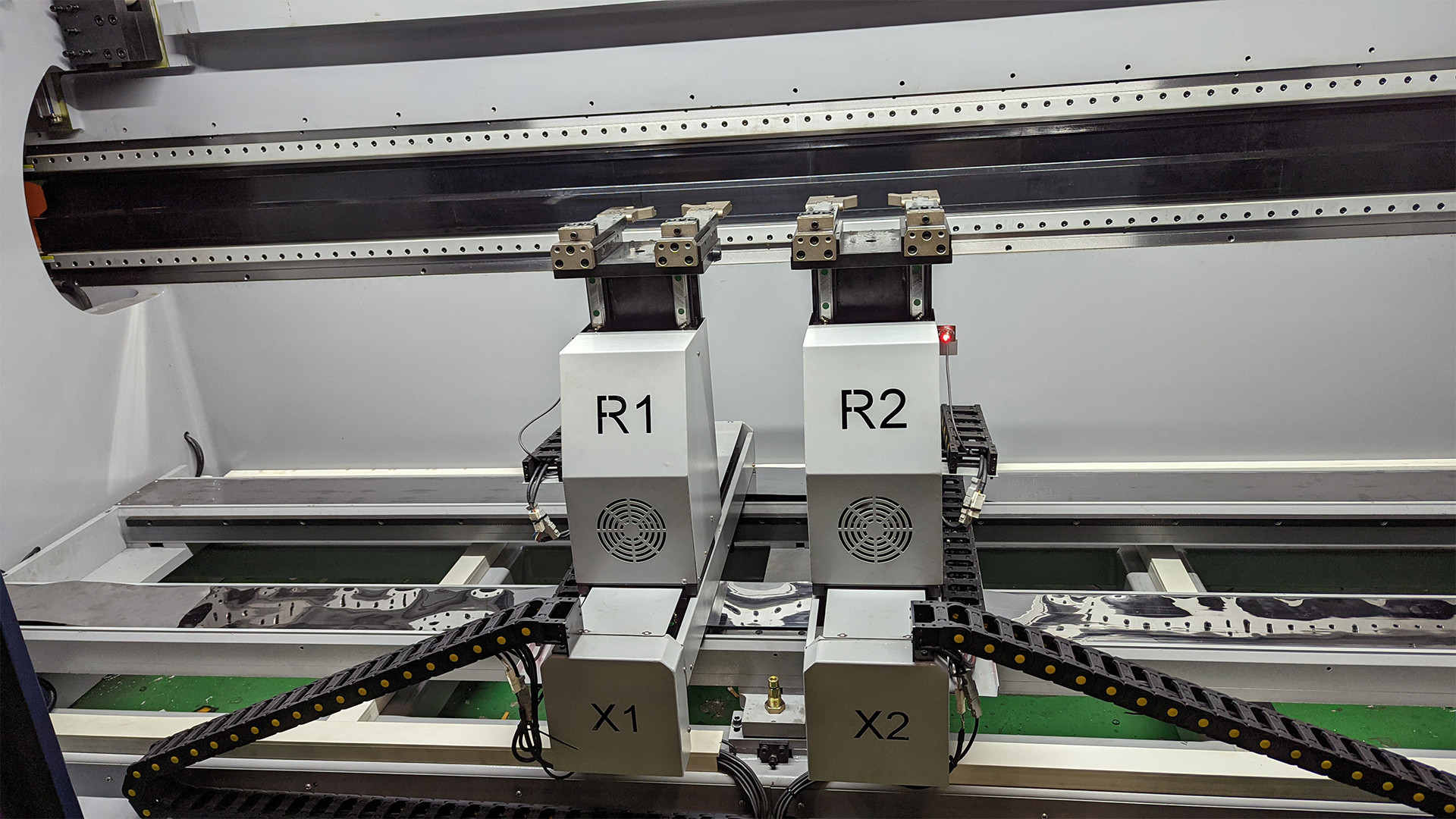

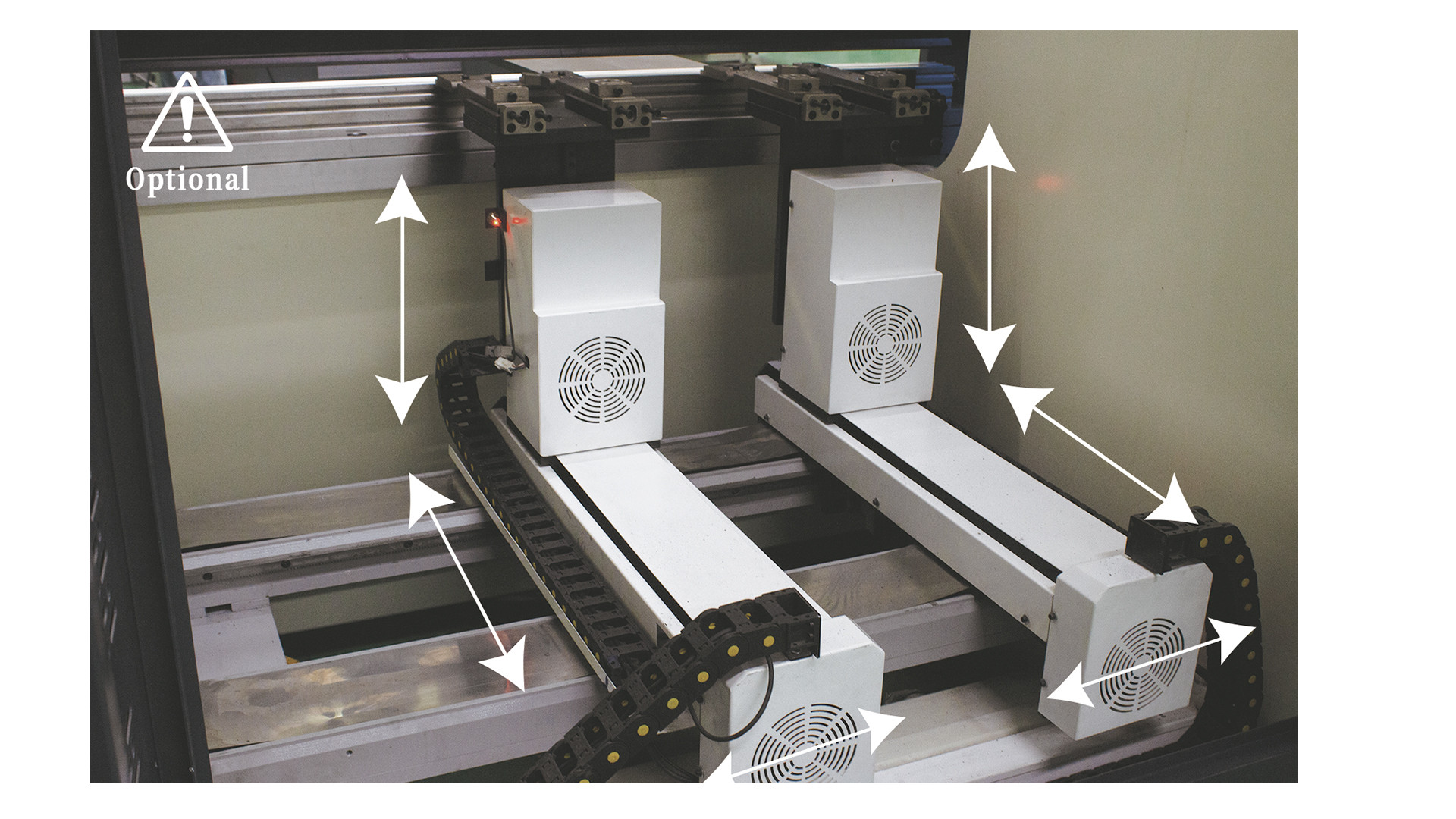

Double linear guide, electric control R axis

Double linear guide, manual control of R axis

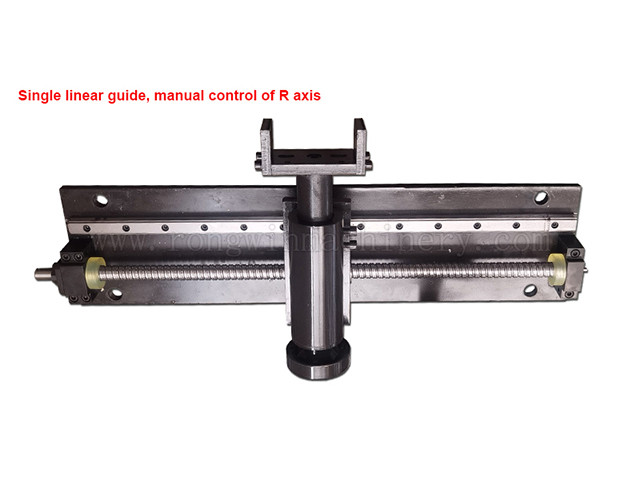

Single linear guide, manual control of R axis

Floor backgauge

Core Advantages

Intelligent positioning technology

1. Equipped with an electric servo motor driven gear rack system, supports digital programming and memory functions, and can store 20 sets of workpiece parameters.

2. Special block design for bevel bending, achieving 30°-150° angle adaptation through separate bending blocks

Industrial-grade durability

1. Key components use imported ball screws (life ≥ 100,000 cycles) and IP65 protection grade guide rails, suitable for high dust workshop

environments

2. The double insurance structure of limit pin + screw prevents positioning deviation caused by block displacement

Quick installation and maintenance

1. Modular component design supports separate replacement of guide rails/slides/stop fingers, reducing maintenance costs

2. Provide door-to-door installation service (limited to East China), 48-hour delivery guarantee

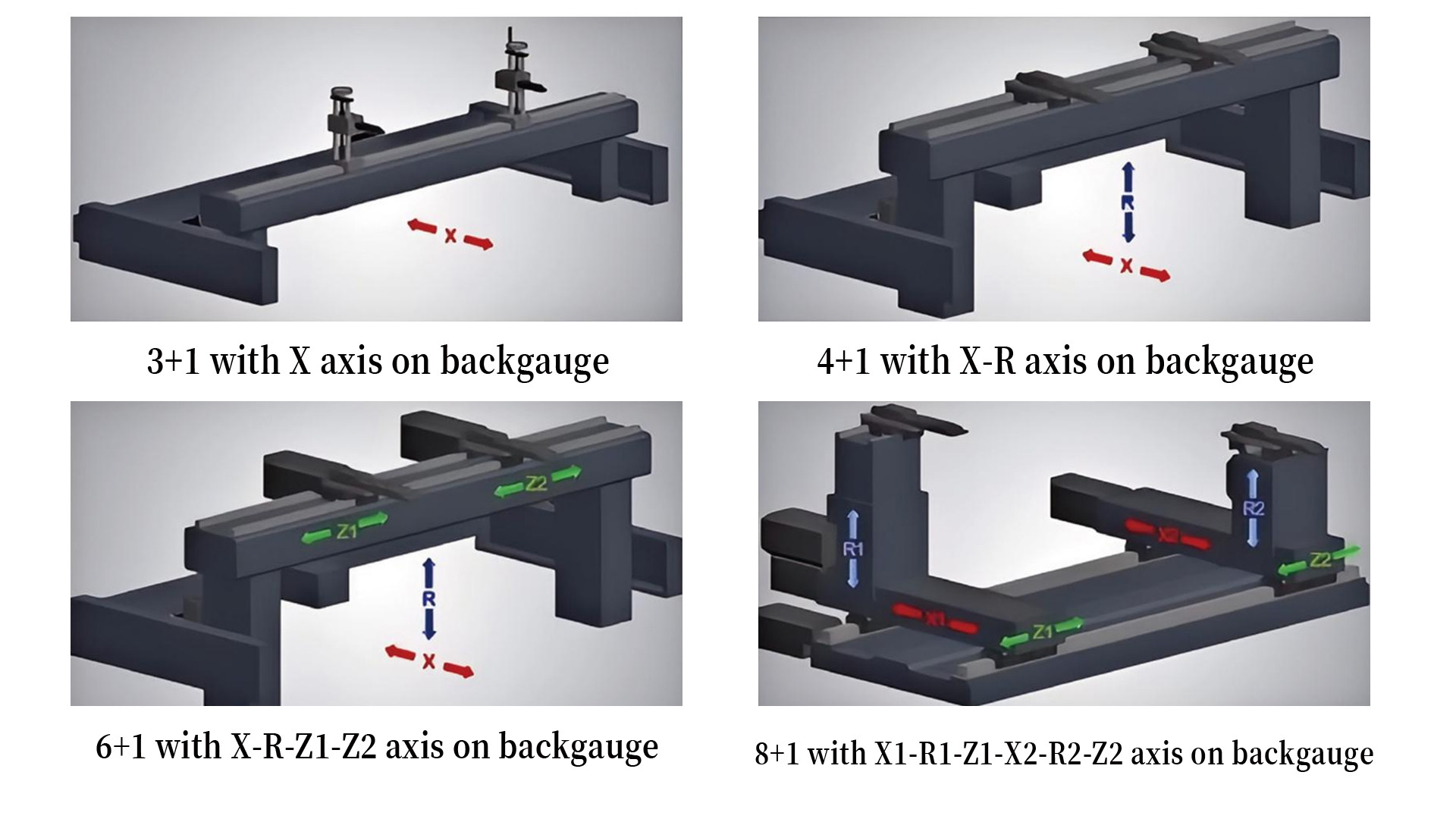

RONGWIN CNC Backgauge Axis

1. Y1, Y2 axes: Control slider up/down movement

2. X1, X2 axes: Control back gauge forward/backward movement

3. Z1, Z2 axes: Control back gauge left/right movement

4. R1, R2 axes: Control back gauge vertical movement

5. V-axis:means automatic crowning compensation

project | Specifications |

Material | High-strength steel (hot-dip galvanized coating ≥ 50μm) |

| Transmission mechanism | Ball screw + linear guide (imported configuration optional) |

Adjustment Dimension | Six-axis linkage (front and back/left and right/lift/angle) |

| Positioning accuracy | ±0.05mm (digital display + manual fine adjustment) |

| Applicable models | CNC bending machine, shearing machine (compatible with 2.5m-3m workbench) |

| Power Requirements | 380V three-phase motor (power optional 1.5kW/2.2kW) |