Press Brake Tooling | 42CrMo Steel | High compressive strength

- Price

- US $1000-100

- Model

- Press Brake Tooling

- MOQ

- 1 piece

Item specifics

- Shaping Mode

- Punching Mold

- Place of Origin

- Anhui, China

- Brand Name

- RongWin

- Product Material

- Steel

- Product

- Press Brake Tooling

- Fitted Machine

- Press Brake Machine

- Optional Material

- 42CrMo/55SiCr/GCr15

- Optional Hardness

- 45~52HRC

- Supply Ability

- 800 Pieces/Month

- Delivery Time

- 20-30days

- Package

- Wooden Box

Review

Description

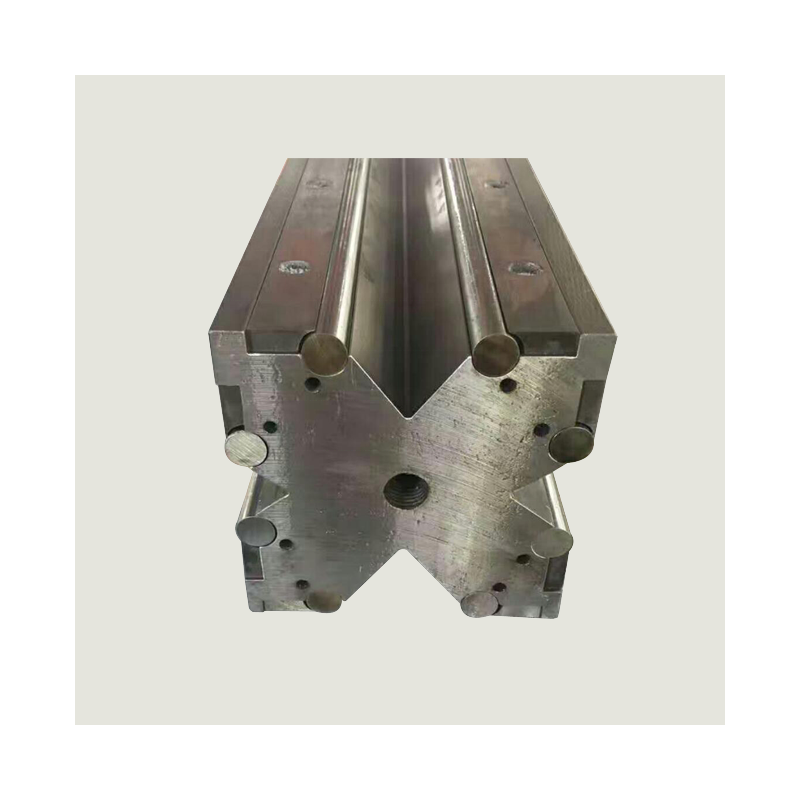

New Die Curling Punch Bending Machine Bending Machine Die

| Items | Content |

| Brand | RongWin |

| Model | Customizable |

| Material | 42CrMo/55SiCr/GCr15 |

| Optional Hardness | 45~52HRC |

weight | 68.00kg |

Insurance | Included |

Color | Customizable |

Size | 835mm |

Surface treatment | Smooth |

Press Brake Tooling Advantages:

Advantages1: High precision molding

In the manufacturing process of precision instrument shells, high-precision bending machine molds can be used to bend metal sheets into an angle within ±0.1°, ensuring that the various components of the instrument shell can be perfectly spliced. This is a precision that is difficult to achieve with manual bending or other simple bending methods.

Advantages2:Good material adaptability

For stainless steel materials with higher hardness, using molds with high hardness and high wear resistance (such as molds made of Cr12MoV steel) can effectively bend them.

Advantages3:Long mold life

High-quality bending machine molds are made of high-strength and high-wear-resistant materials, such as 42CrMo steel, SKD11 steel, etc. After proper heat treatment, these materials can withstand a large number of bending operations without severe wear or damage.

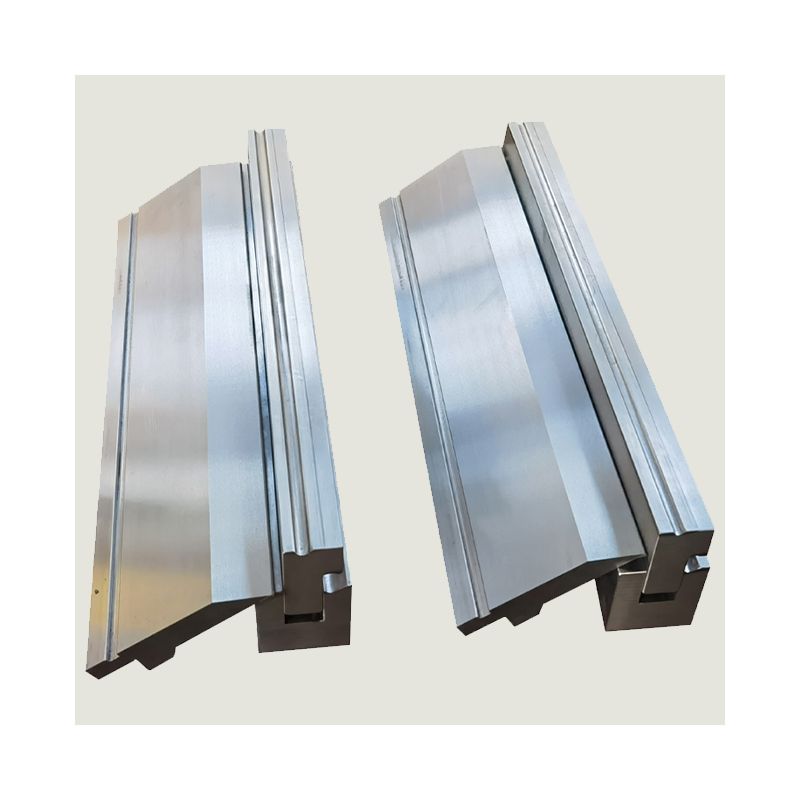

No Indentation Mold Rolla-V DieOptiona

| Items | Content |

| Brand | RongWin |

| Model | Rolla-V Die Optiona |

| Material | 42CrMo/55SiCr/GCr15 |

| Optional Hardness | 45~52HRC |

weight | 68.00kg |

Insurance | Included |

Color | Customizable |

Size | 835mm/Customizable |

Surface treatment | Smooth |

Advantages:

Advantages1:Not easy to deform

It can follow the bending plate moving, does not cause bending mark, and can ensure that the hole does not deform after bending.

Advantages2:Rolla-V Efect

Ensures no marks on the sheet surface during bending,maintaining a smooth and flawiess finish.

Advantages3:Hole Protection

Designed to prevent hole deformation, preserving the originalsize and shape ofthe holes, ensuring precision and aesthetic quality

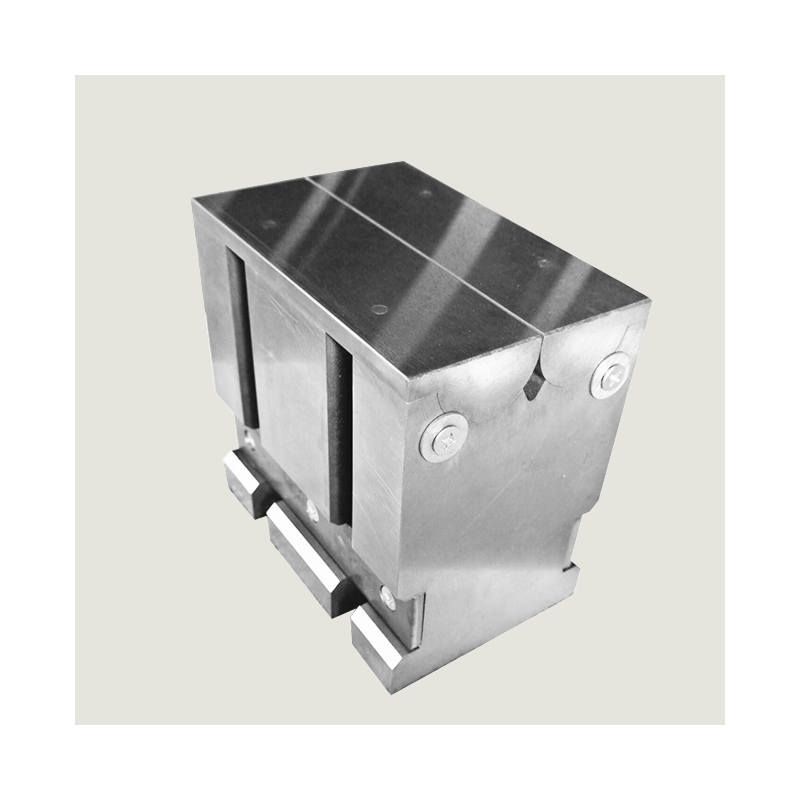

Multi-V Ball Die

| Items | Content |

| Brand | RongWin |

| Model | Multi-V Ball Die |

| Material | 42CrMo/55SiCr/GCr15 |

| Optional Hardness | 45~52HRC |

weight | 68.00kg |

Insurance | Included |

Color | Metallic |

Size | 835mm/Customizable |

Surface treatment | Smooth |

Package | Wooden crate with soft film layers inside |

Use | Used on press brake machine |

Advantages:

Advantages1: High precision molding

The rollers move with the plate to reduce friction and indentation, suitable for long plates and contin uous bending operations

Advantages2:High Efciency

Increases bending efciency, reduces reject rates, and enhancesoverall production quality and efficiency.

Advantages3:Flexible Design

Some mark-free dies use fexible materials (like polyurethane) orball designs to reduce friction and contact pressure, making themsuitable for long sheets and continuous bending operations.

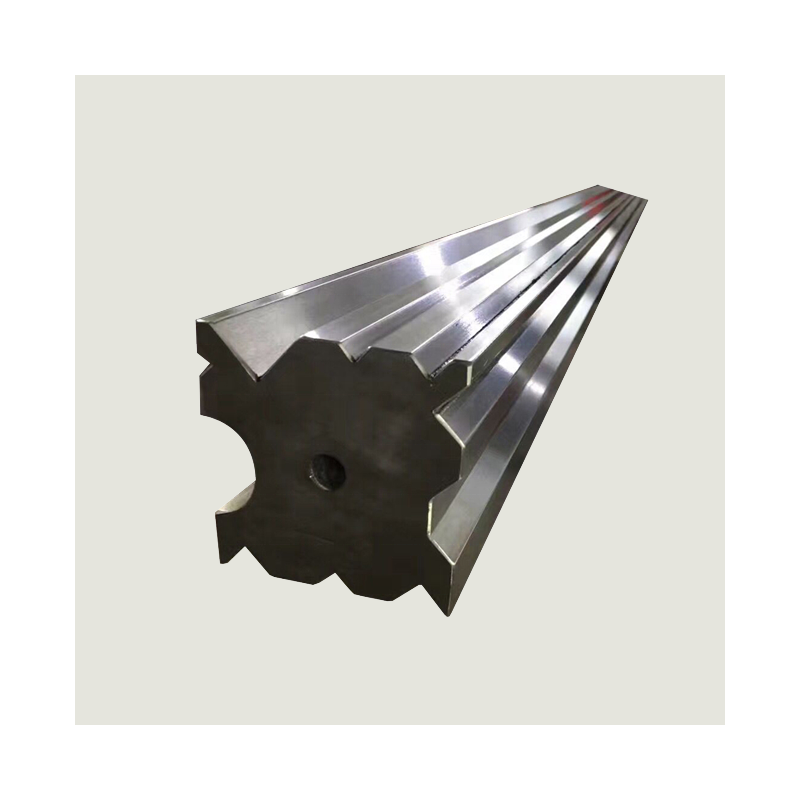

4V Die Press Brake Metal Die

| Items | Content |

| Brand | RongWin |

| Model | 4V Die |

| Material | 42CrMo |

| Optional Hardness | 45~52HRC |

weight | 68.00kg |

Hardness | 45-50HRC |

Color | Black |

Size | Customized Size |

Surface treatment | Smooth |

Package | Wooden Packing |

Use | Used on press brake machine |

Product Name | 4V Die |

Option | Black-antirust |

Advantages:

Advantages1: Product quality stability

In the long-term production process, 4V Die mold can ensure the stability of product quality

Advantages2:Customized mold

4V Die can be designed and manufactured according to the specific needs of customers. Each customer's product may have different shapes, sizes, precision requirements, etc. This mold can be customized according to these special requirements.

Advantages3:Automation potential

It also has the potential for automated processing. On a production line with a high degree of automation, the 4V Die mold can be integrated with automated equipment to achieve a series of operations such as automatic feeding, automatic bending and automatic discharging.