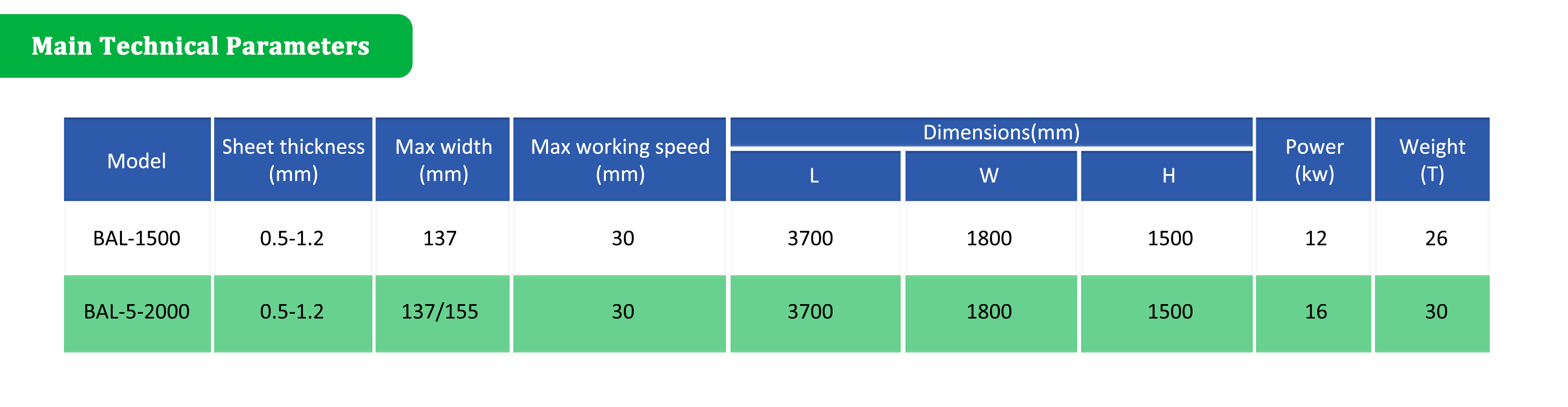

RONGWIN Efficient Spiral Duct Machine | Applied to Automated Production

- Price

- US $10000-9000

- Model

- spiral duct machine

- MOQ

- 1 piece

Item specifics

- Weight

- 1280KG

- Warranty

- 1Year

- Dimension(L*W*H)

- 2620*1920*2100mm

- Name

- Spiral duct machine

- Pipe shape

- Circle Pipe

- thickness

- 0.4-1mm

- Color

- Customer Selected

Review

Description

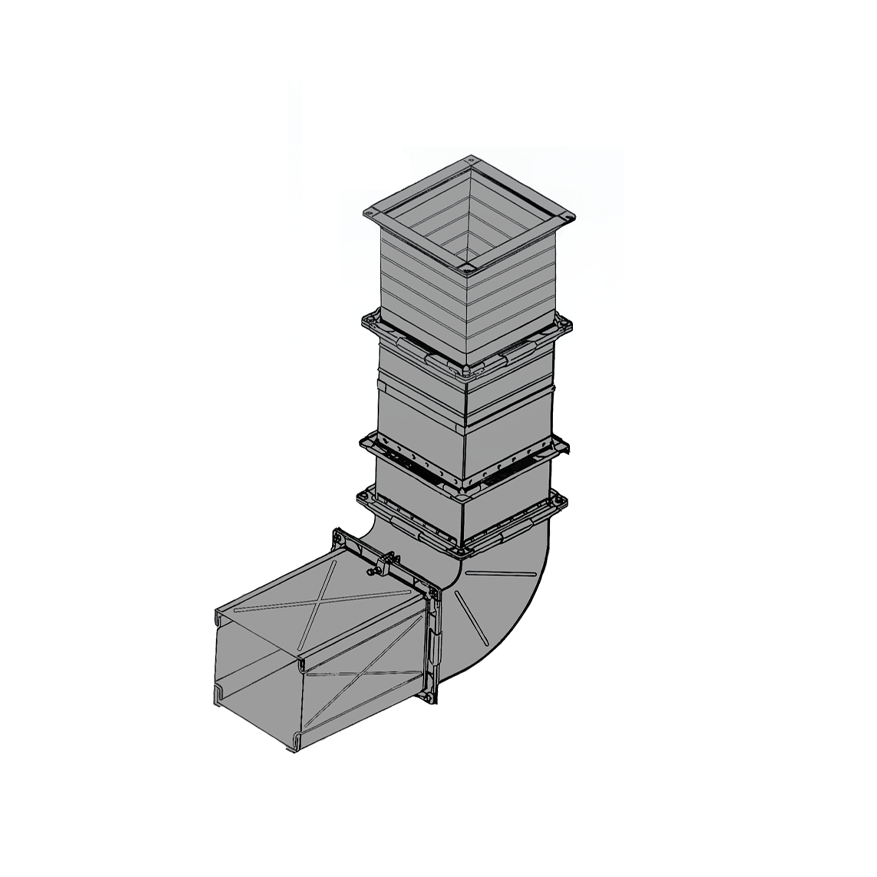

Square Duct Processing Process.1

Duct Coil Leveling Laser Cutting

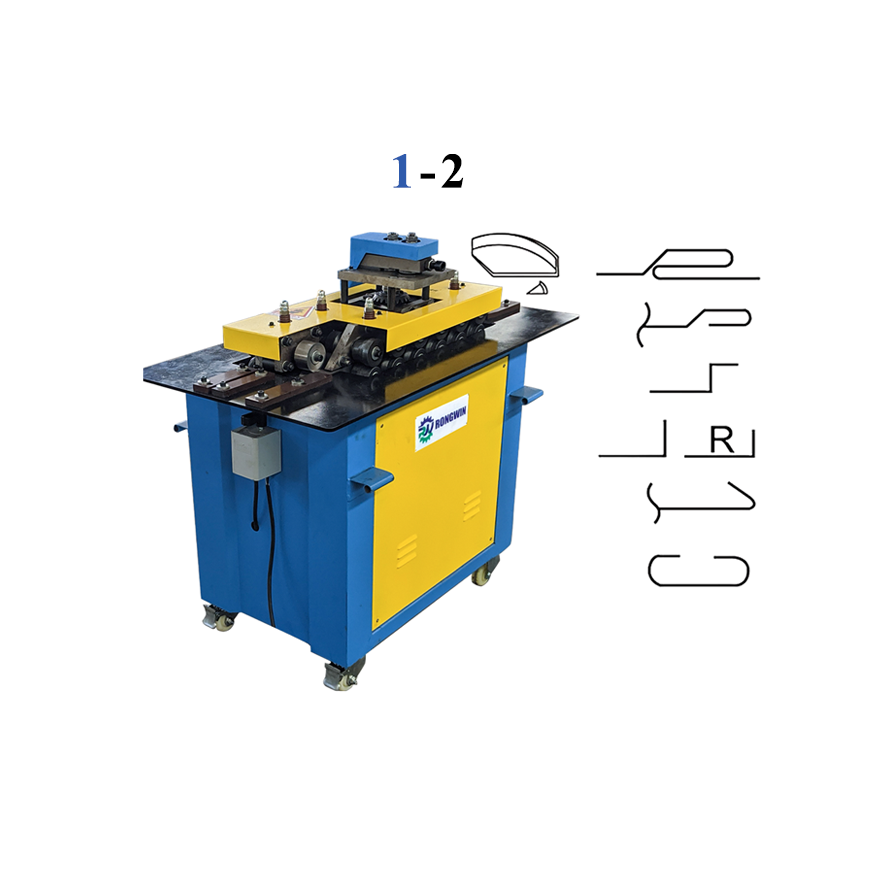

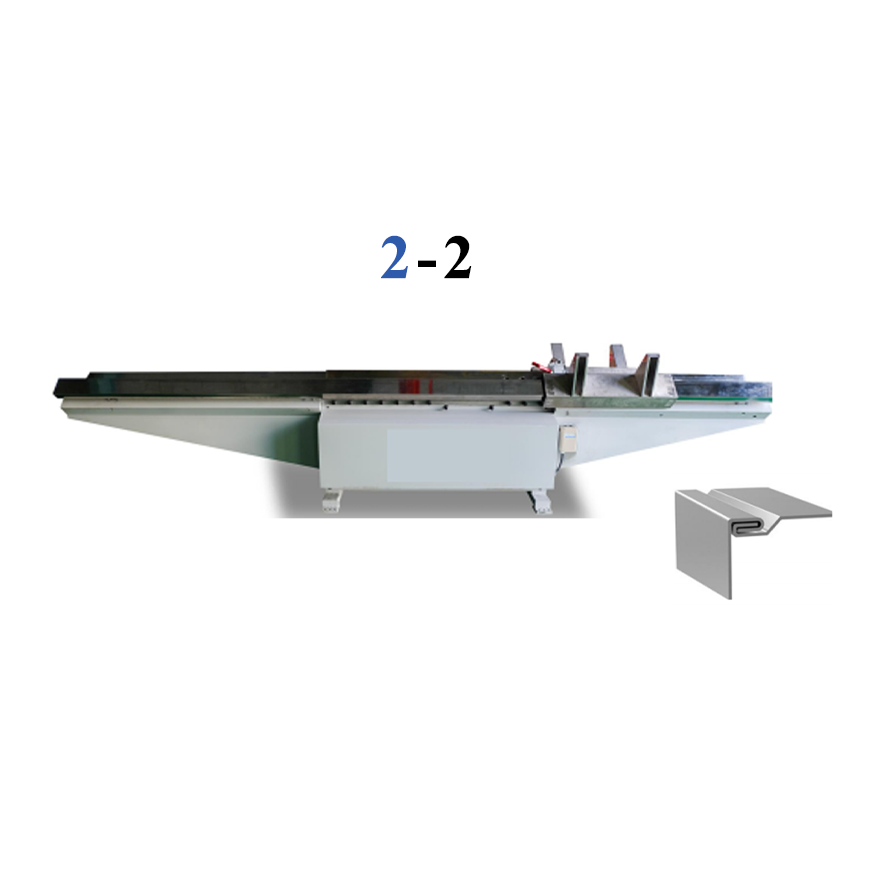

Lock Forming Machine

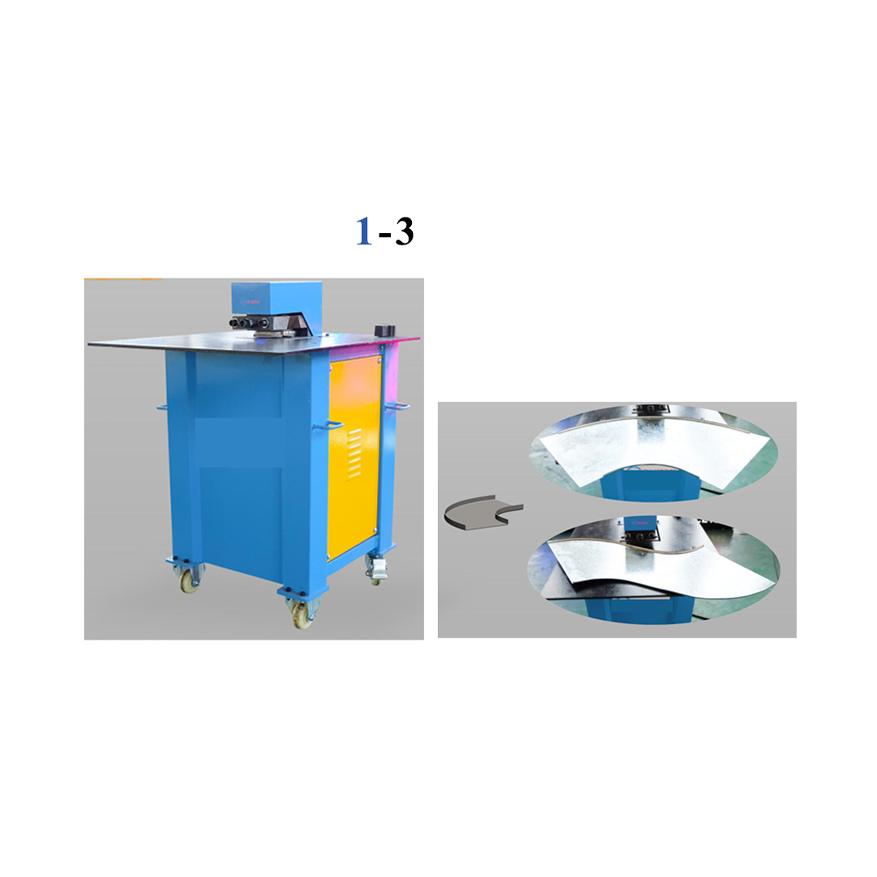

Elbow Lock Forming Machine

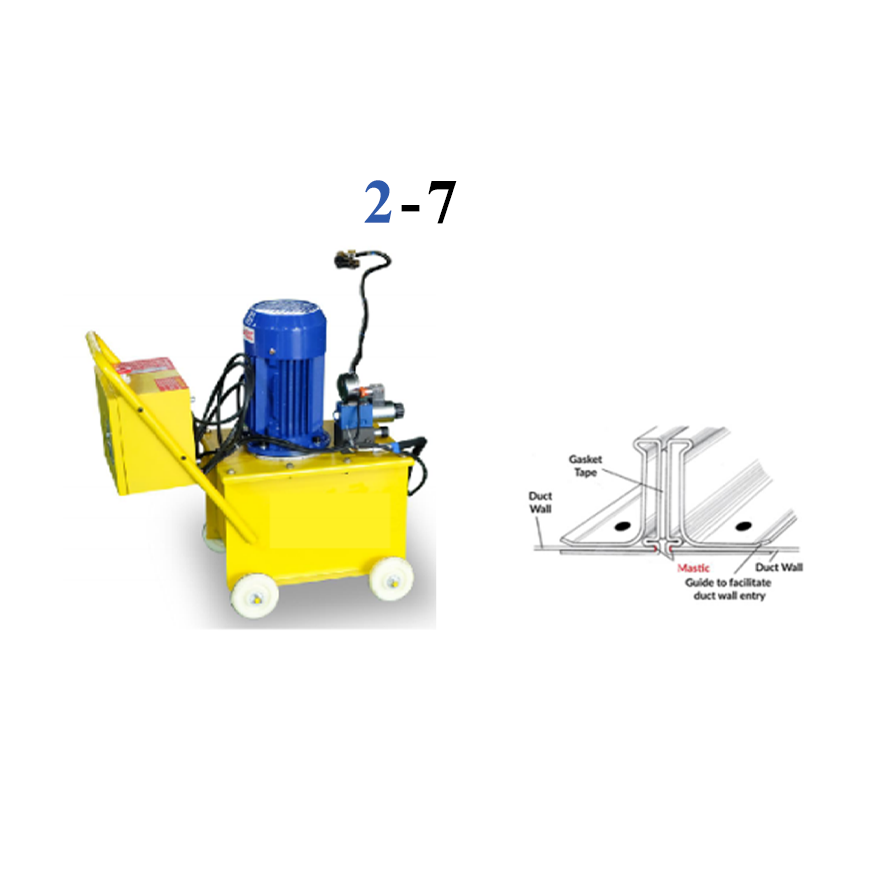

TDC Flange Machine

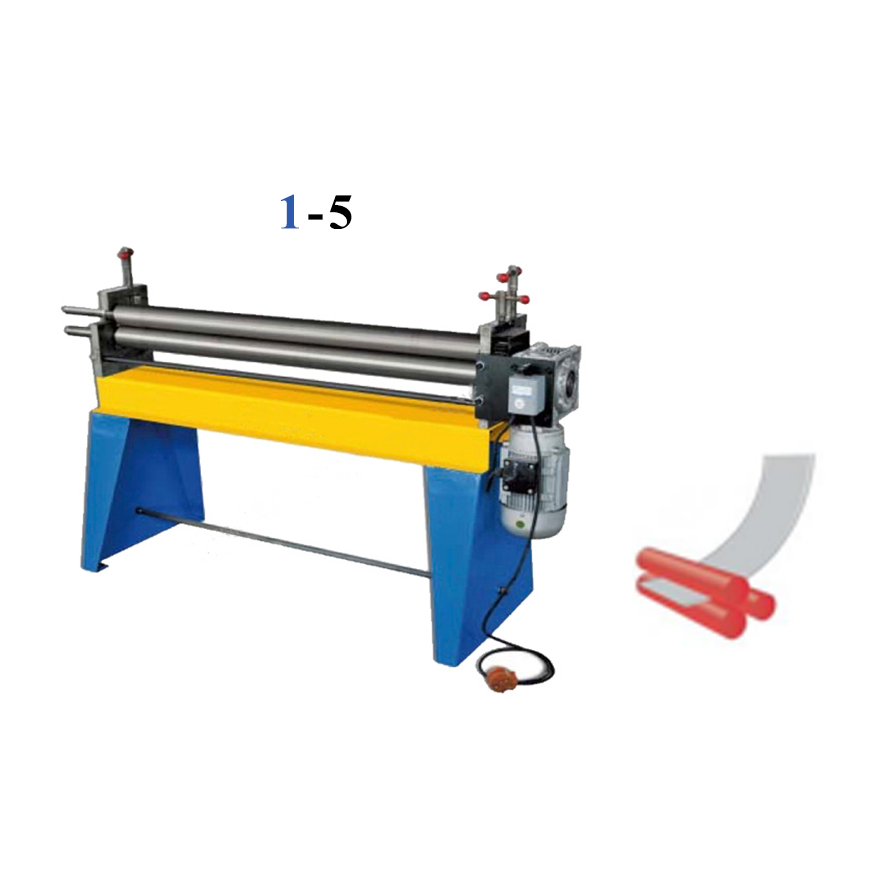

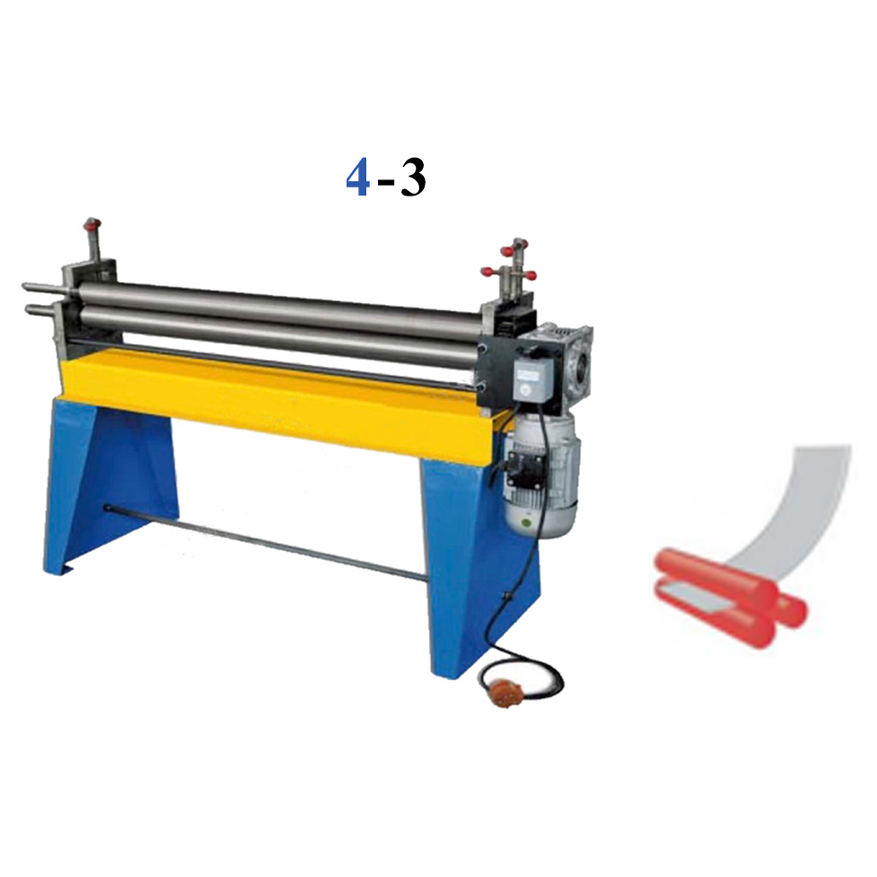

Electric Rolling Machine

Pneumatic Seaming Hammer

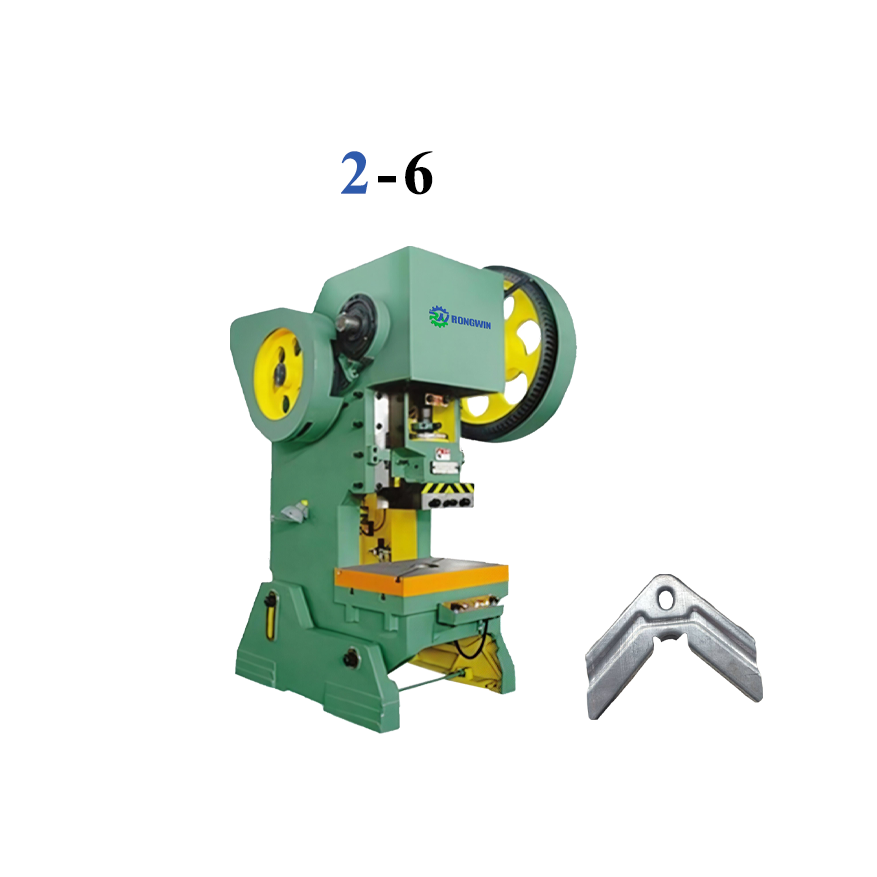

TDC Corner Code Productlon Line

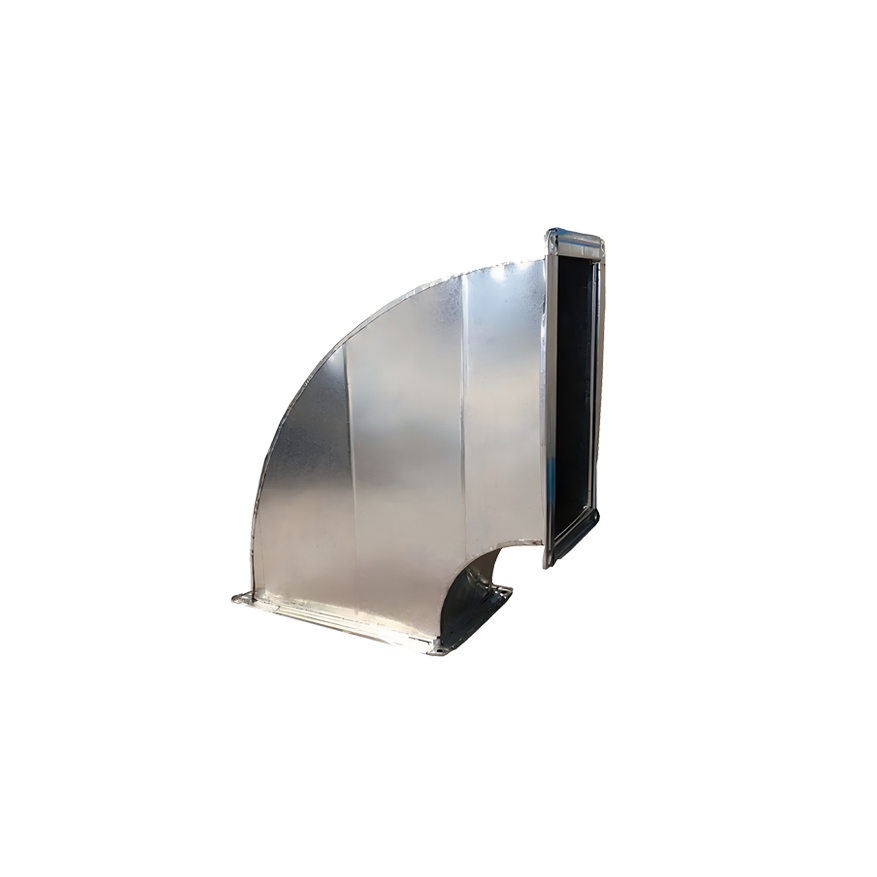

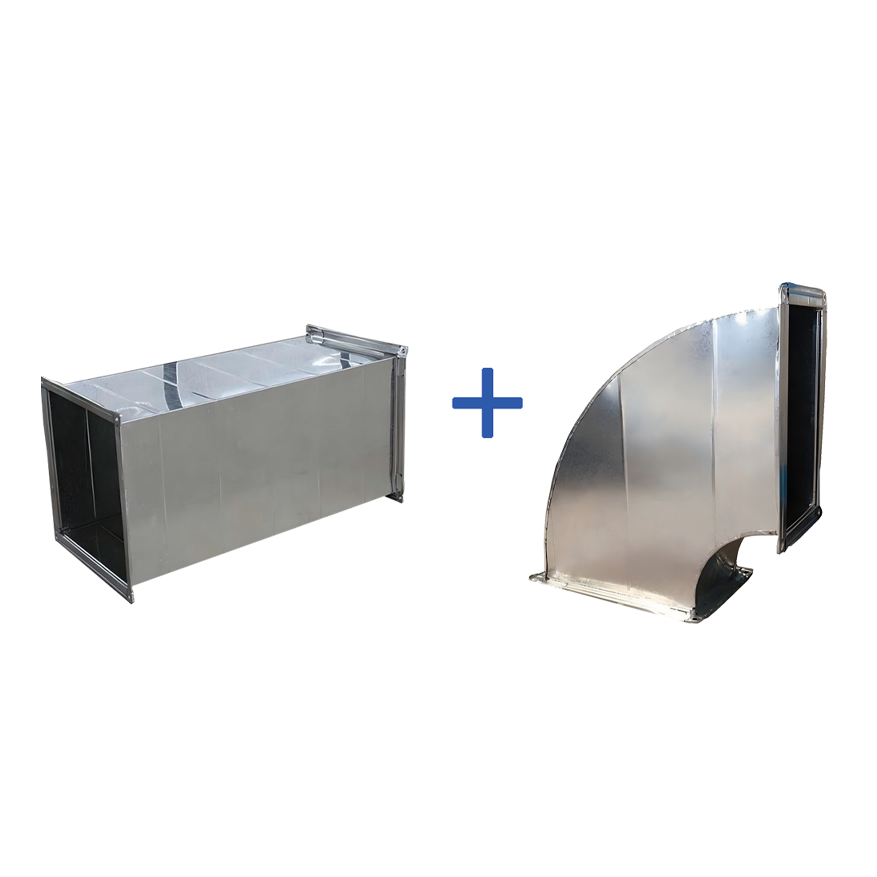

Finished product

Square Duct Processing Process.2

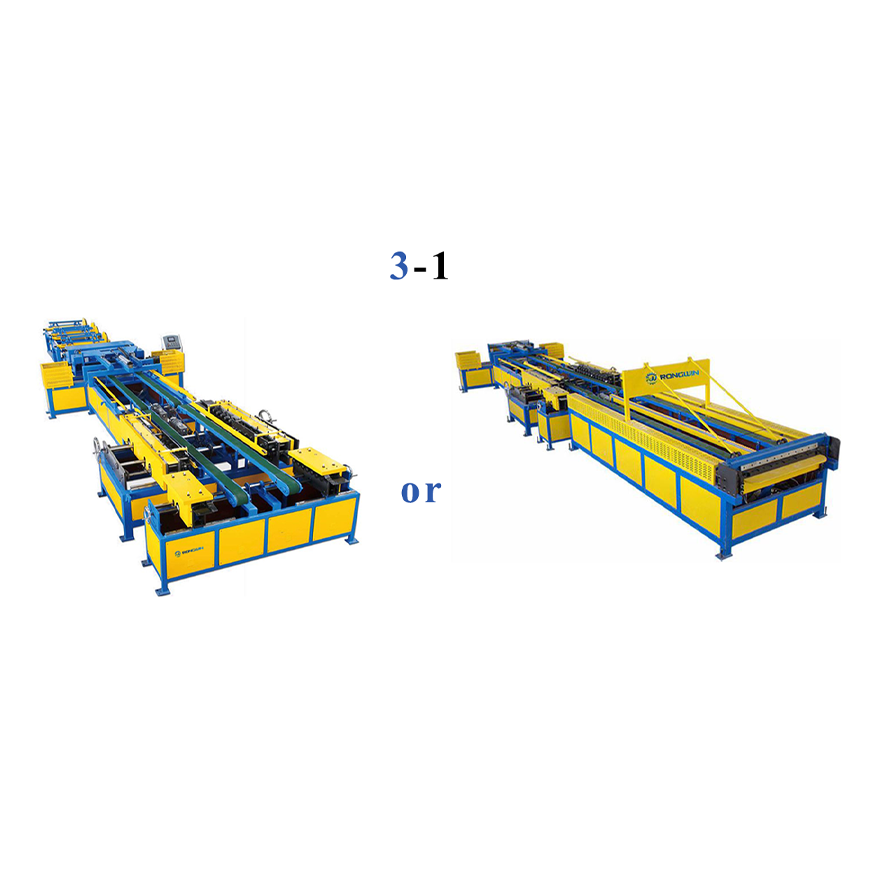

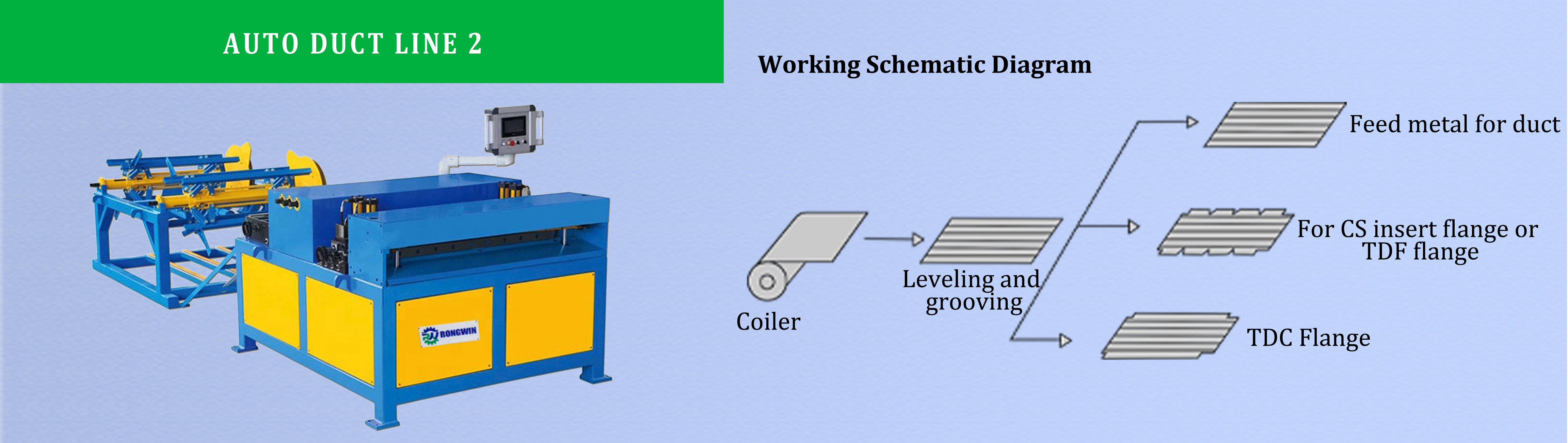

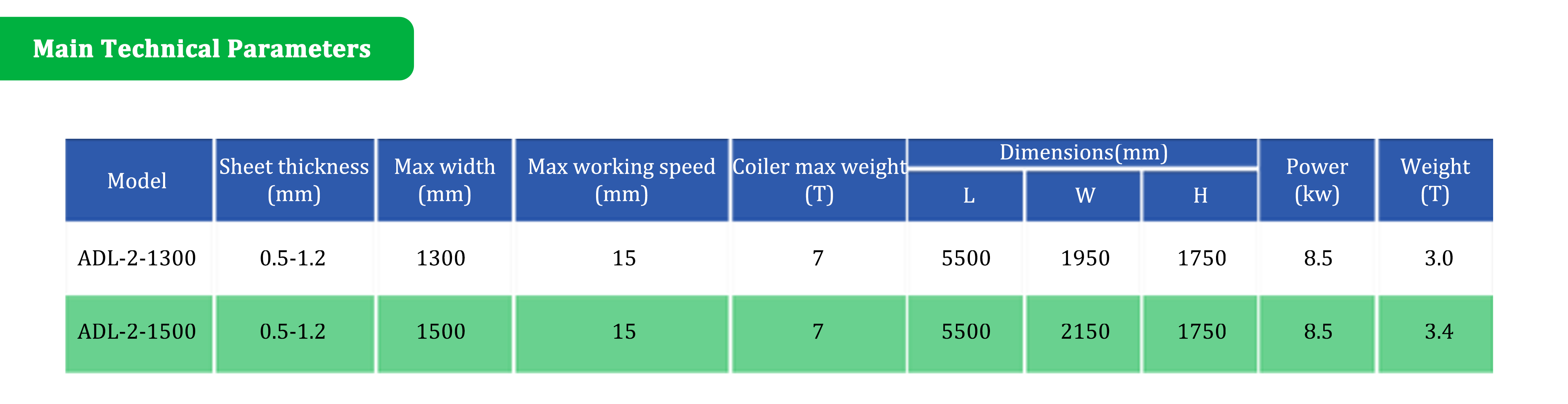

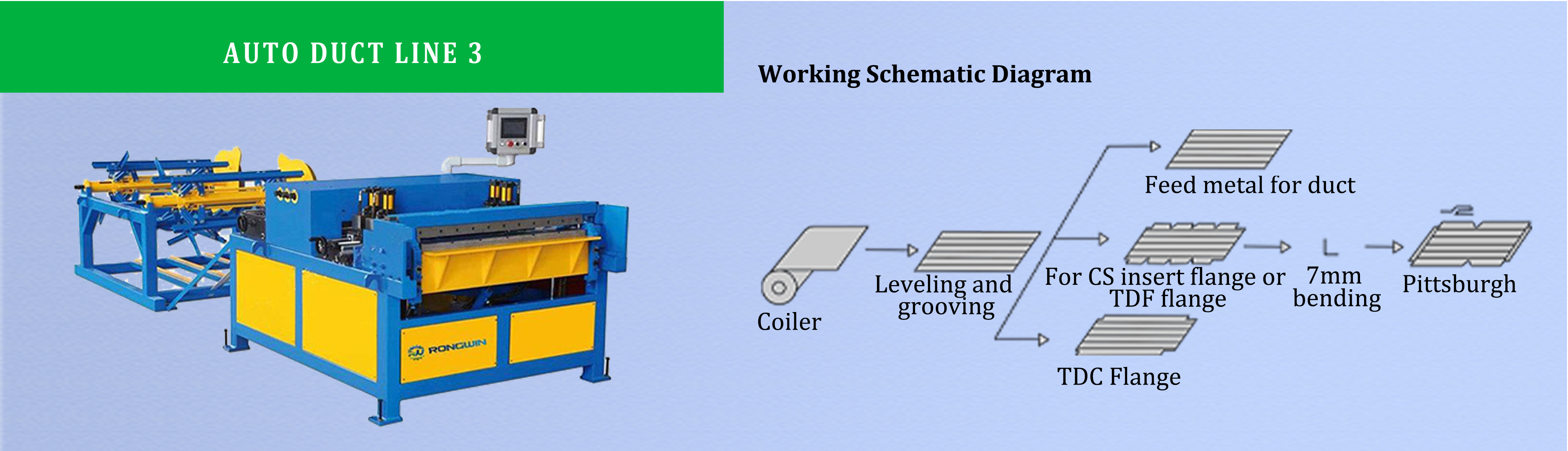

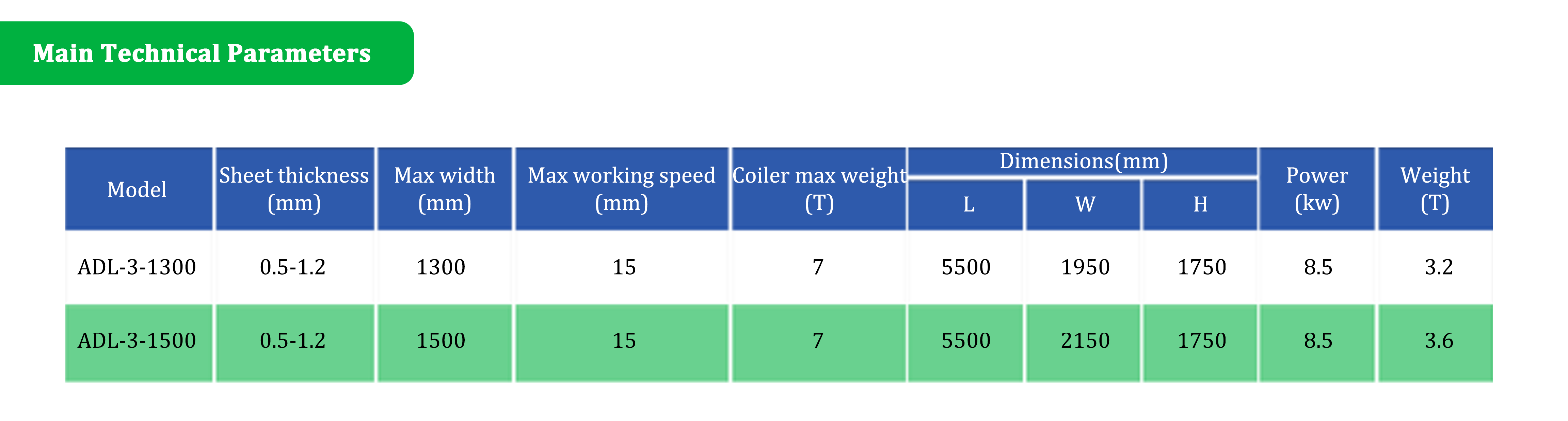

Auto Duct Line 2/Auto Duct Line 3

Duct Zipper Machine

TDC Flange Machine

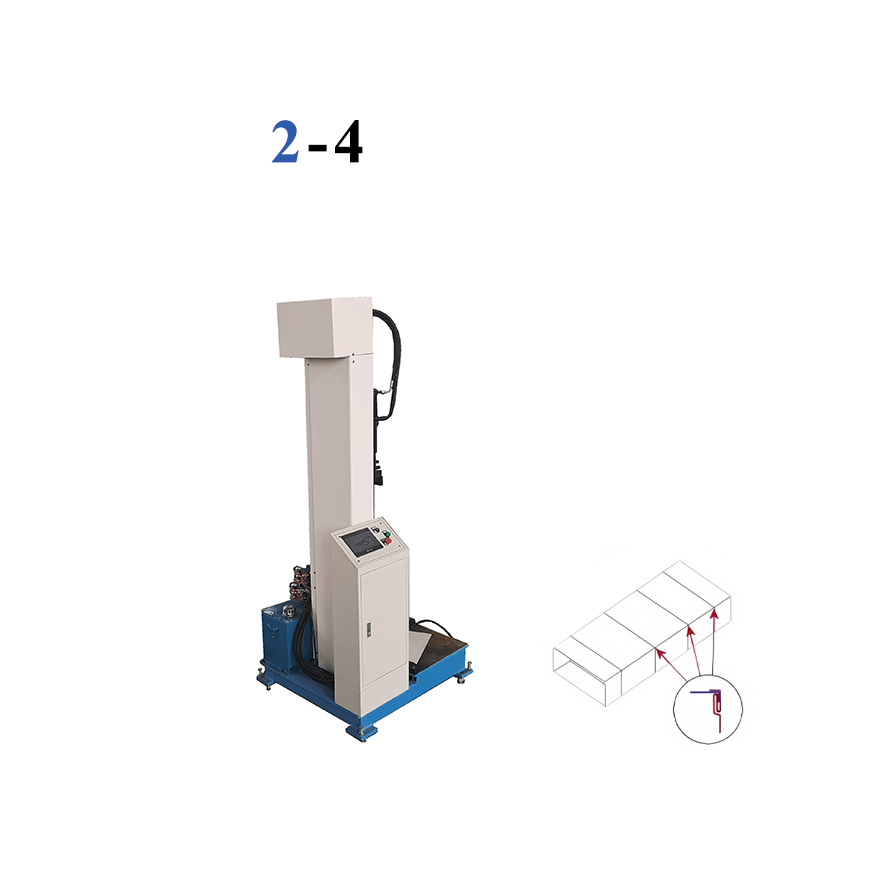

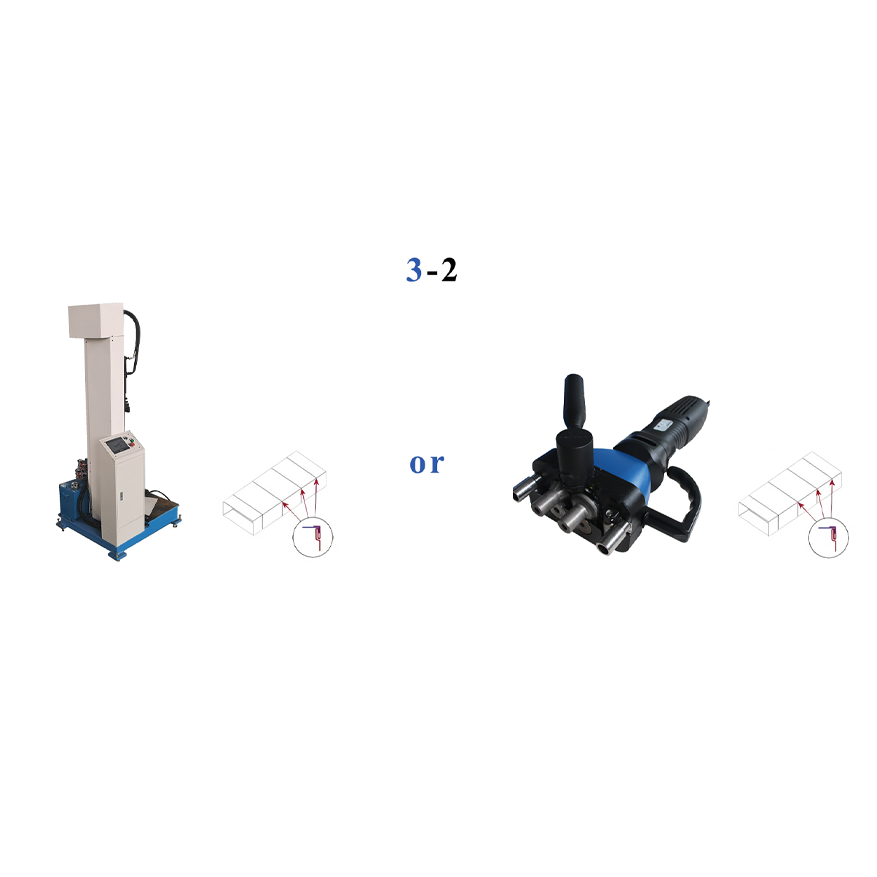

Hydraulic Lock Seam Machine

Hand Folding Machine

TDC Corner Code Productlon Line

Hydraulic Rivetless Riveting

Machine

Finished product

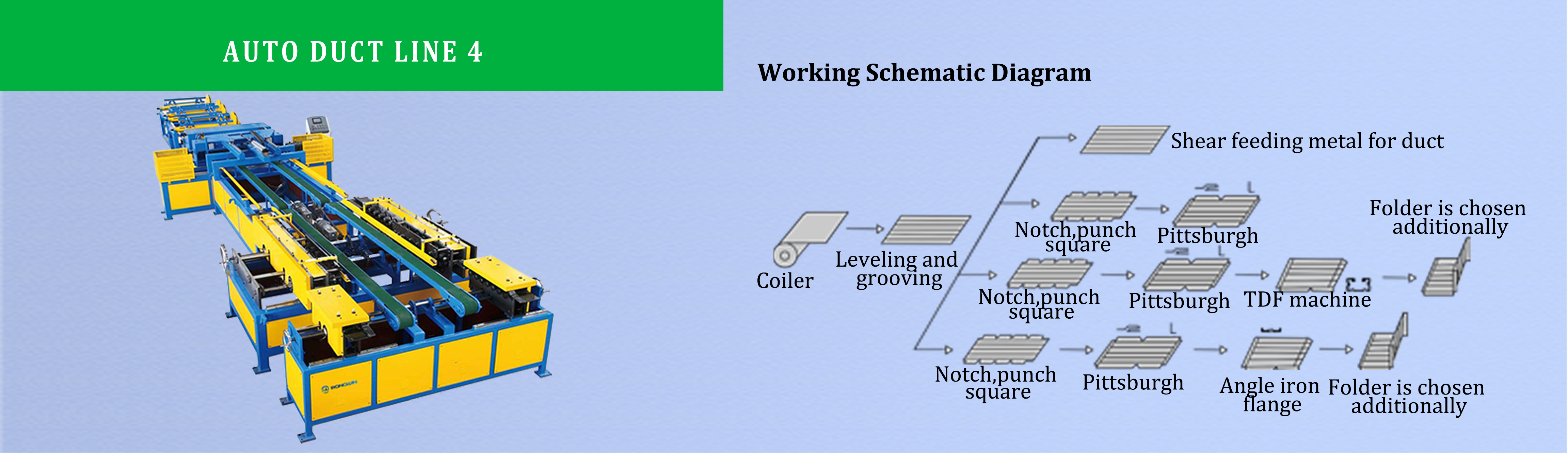

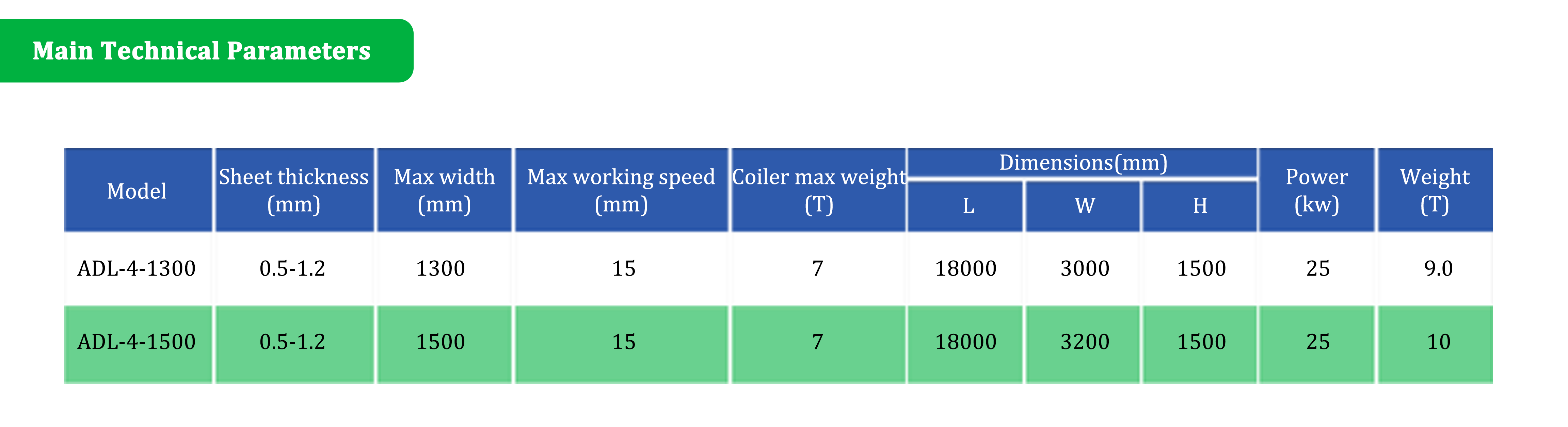

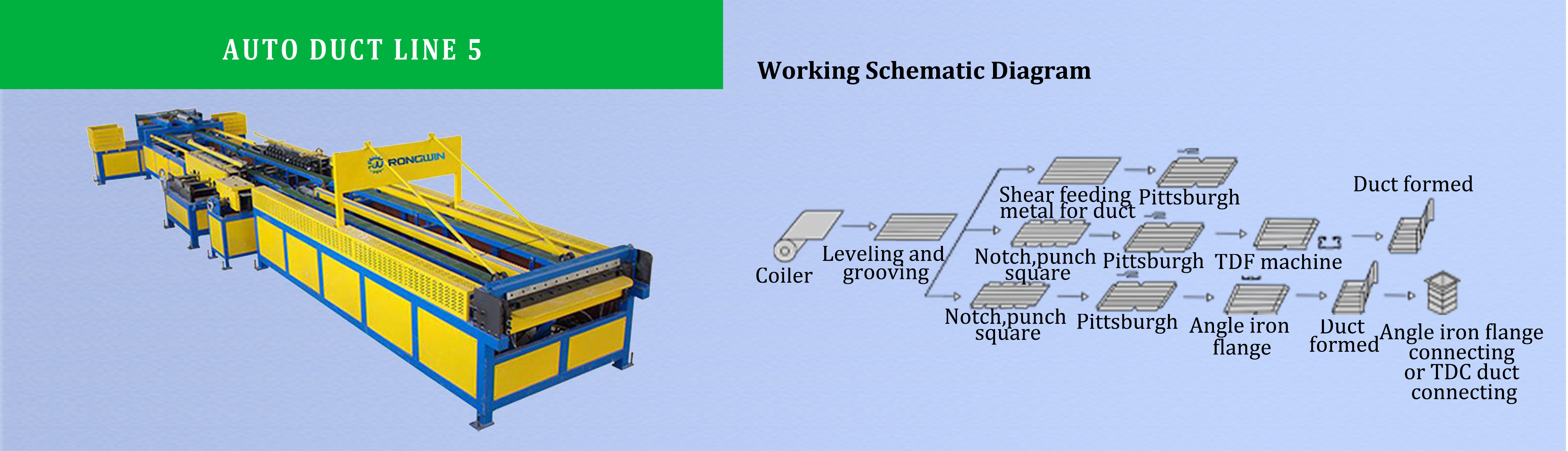

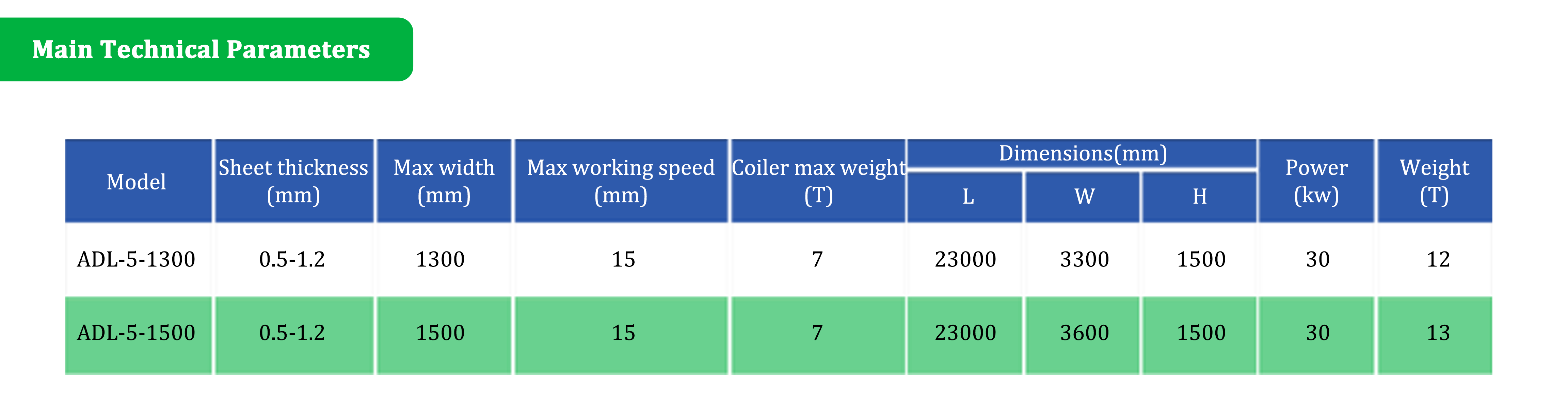

Auto Duct Line 4/Auto Duct Line 5

Hydraulic Lock Seam Machine/Electric Lock Seam Machine

Pneumatic Corner Code

Assembly Machine

Finished product

Square Duct Processing Process.3

Duct C Clamp Production Line

Finished product

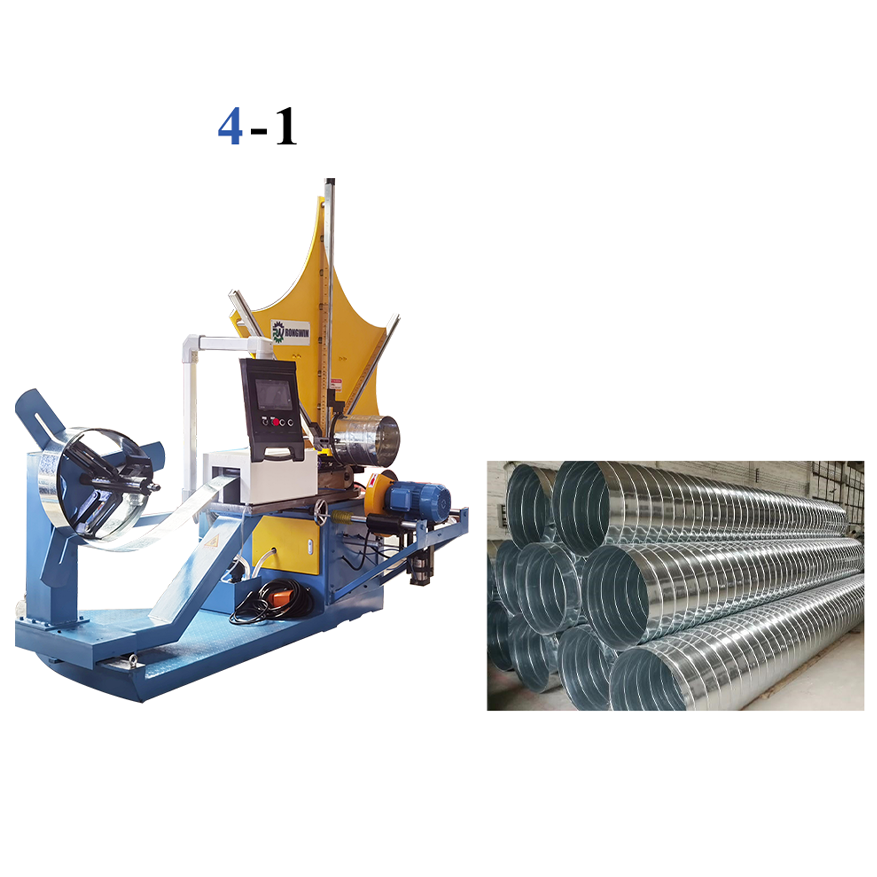

Spiral Duct Processing Process

Spiral Duct Machine

Duct Coil Leveling Laser Cutting

Machine

Electric Rolling Machine

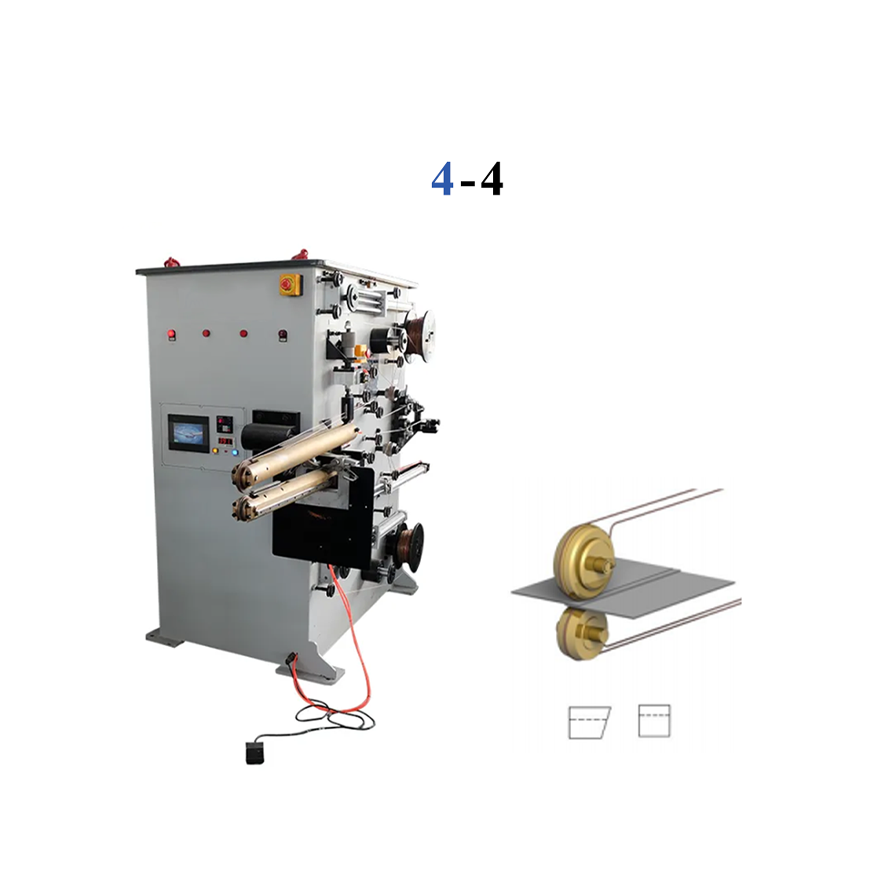

Round Duct Stitch Welding

Machine

Round Duct Rotary Beading Machine

Electric Elbow Machine

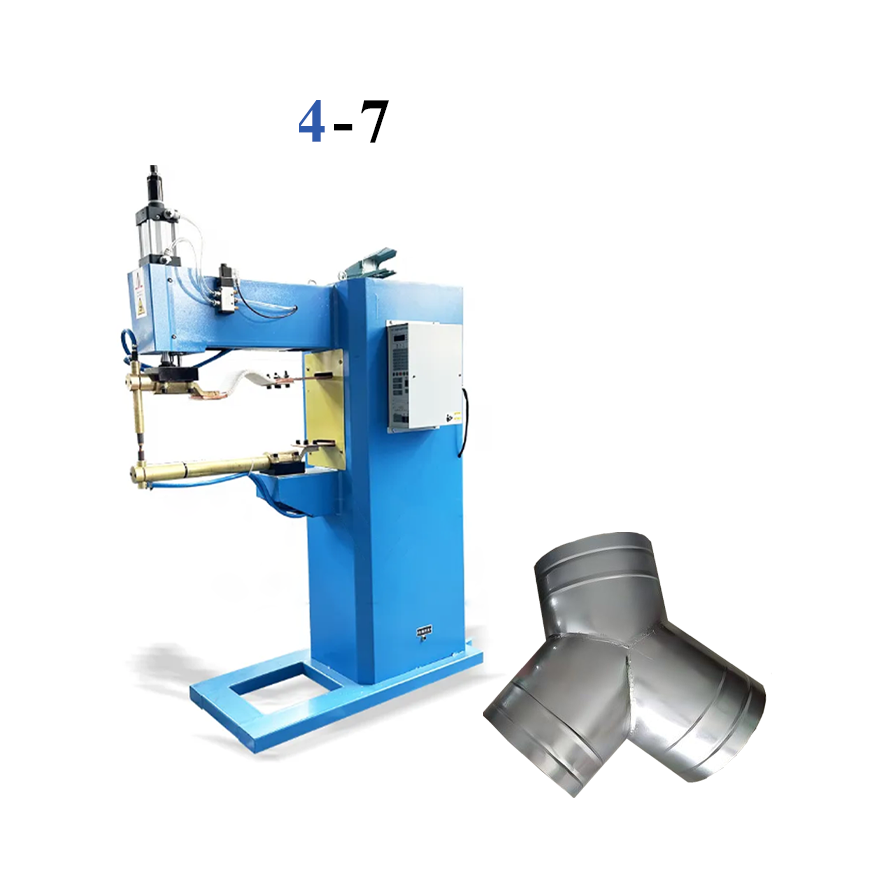

Round Duct Spot

Welding Machine

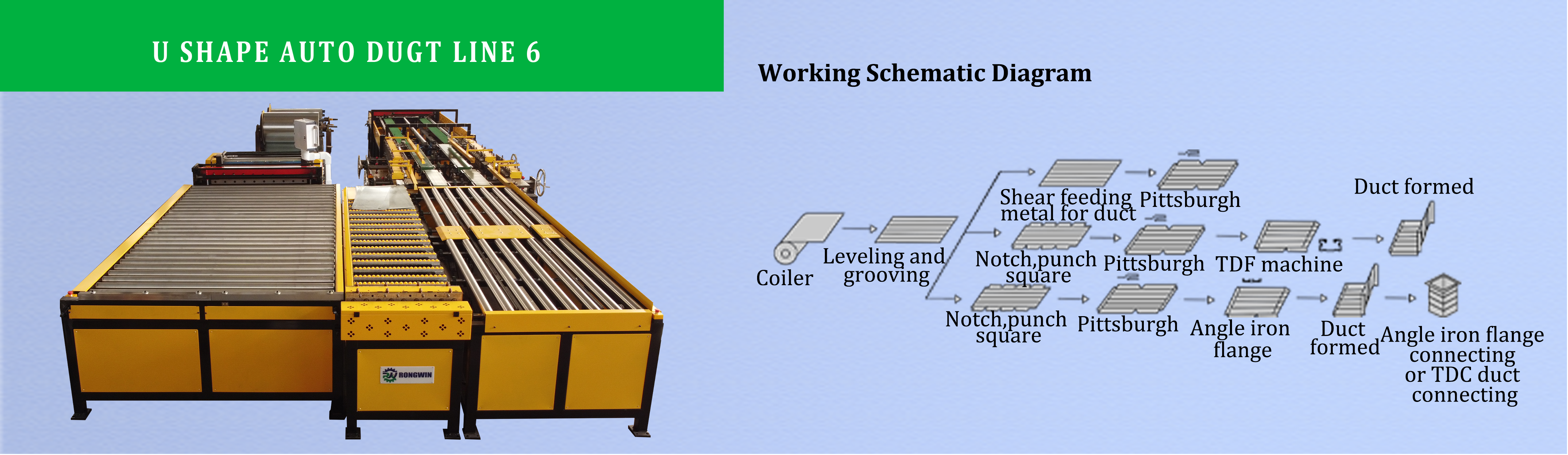

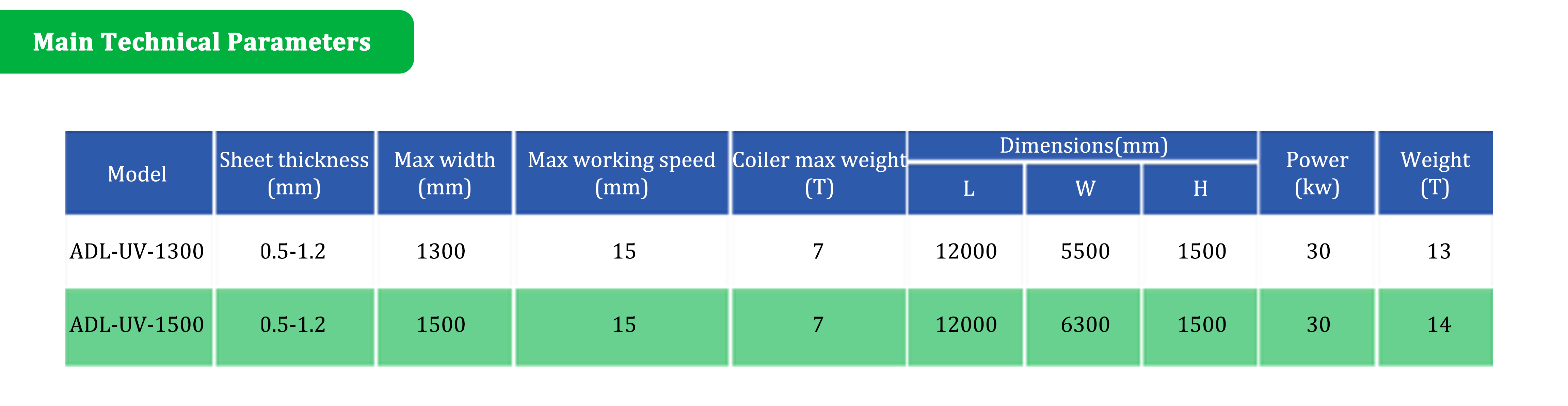

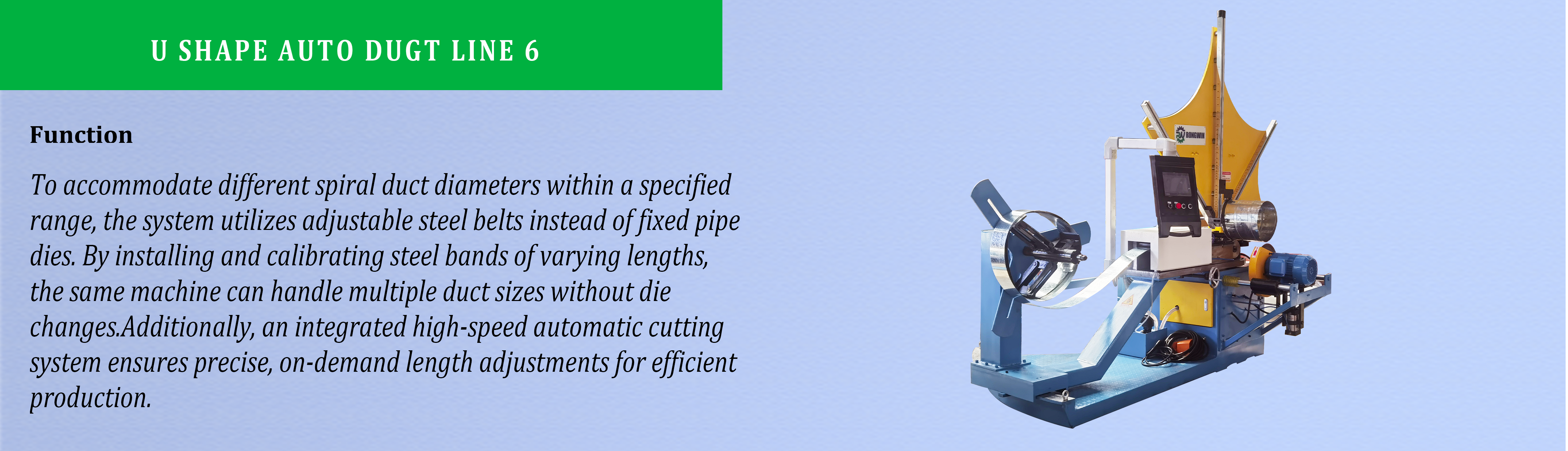

U-Shape Duct Processing Process

Round Pipe

Elliptical expander

Finished product

Product Introduction

Basic Confguration

1.0ne electric coil cradles, two material trays 2.0ne set of leveling and beading 3.Hydraulic angle-shearing machine with four seats of die 4.Hydraulic-shearing machine, bending machine, press machine 5.A set of CNC control system and software

Basic Confguration

1.One electric coi cradles, two material trays (5-7t each roll) 2.One rack 3.One host (line 3 host) 4.One mechanical arm dutching, locating and transferring platiom 5.One displacement type locking machine 6.One set of computer controlling system

Basic Confguration

1.Two electric coil cradles,four material trays (5-7t each roll) 2.0ne rack 3.0ne host (line 2 host) 4.0ne mechanical arm clutching, locating and

transferring 5.0ne displacement type locking machine 6.0ne duplexTDF flange forming machine 7.0ne duplex angle steel flange forming machine

8.0ne set of computer controlling system

Basic Confguration

1.Two electric coil cradles,four material trays (5-7t each roll) 2.One rack 3.0ne host (line 2 host) 4.0ne mechanical arm clutching, locating and

transferring 5.0ne displacement type locking machine 6.0ne duplexTDF flange forming machine 7.0ne duplex angle steel flange forming machine

8.0ne servo feeding platfom 9.0ne hydraulic folding machine 10.0ne set of computer controlling system

Basic Confguration

1.Two electric coil cradles,four material trays (5-7t each roll) 2.One rack 3.0ne host (line 2 host) 4.Two stainless steel roller conveyer platforms

5.0ne fxed joint locking machine 6.0ne duplex TDF flange forming machine 7.0ne duplex angle steel flange forming machine 8.0ne serwo feeding

platfom 9.0ne hydraulic folding machine 10.0ne set of computer controlling system

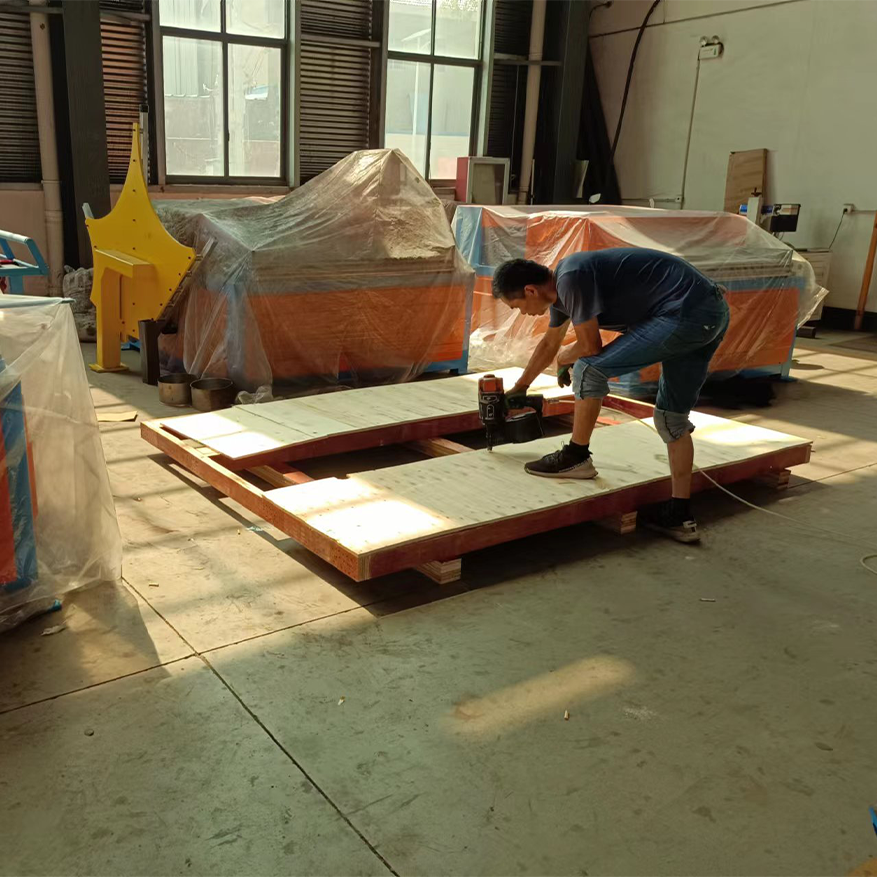

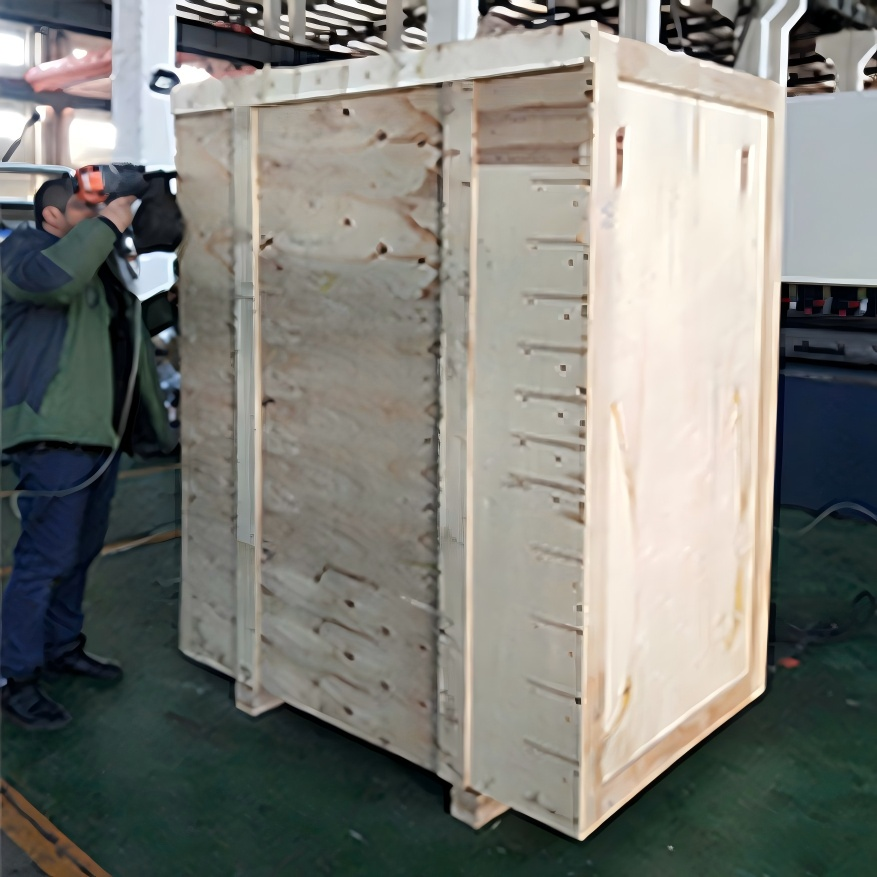

Product Delivery

Customer Reviews

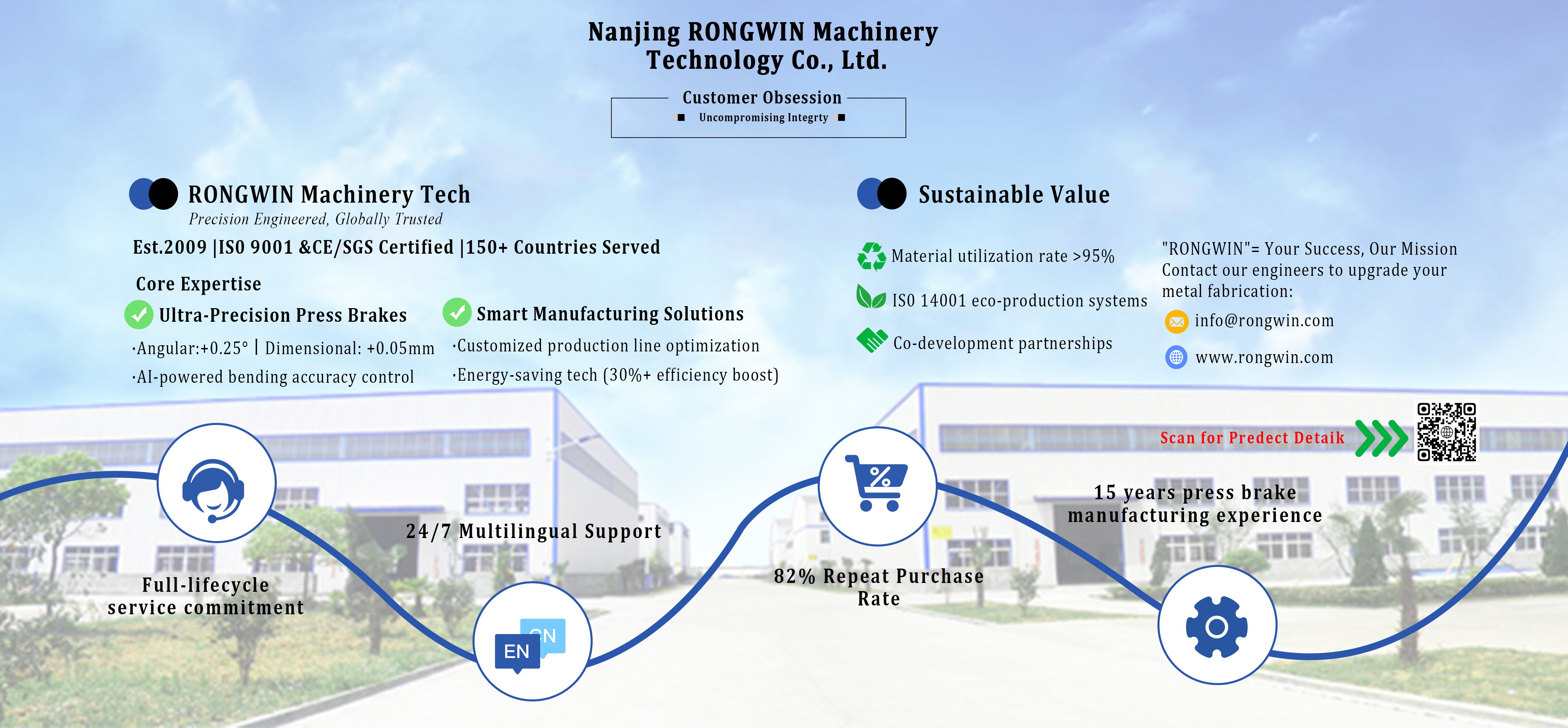

Company linformation

Plant and Equipment

Certificate

Qur Team

Customer Stories

Indian Customers

Mexican Customers

Indian Customers

Romania Customers

Saudi Arabia Customers

Ethiopian Customers

Lithuanian Customers

Ukrainian Customers

Indian Customers

Exhibition

Shipping & FAQ

Q1: Can you give us a better price?

A: The more products you buy, the more discounts you get.

Q2: Can I make a OEM order?

A: We can supply different sizes.our products can be

customized.But you need to tell us more detailed requirements.

Q3: How does your factory do regarding quality

control?

A: "Quality is priority." Our team always attach great

importance to quality controlling from the very beginning

to the verv end.

Q4: What's your MOQ order?

A: Usually it's a minimum order. If you need more, we can

negotiate a discount.

Q5: How to find the right product?

A: You can provide us with photos or your requirements,

and we can give you Suggestions as appropriate.