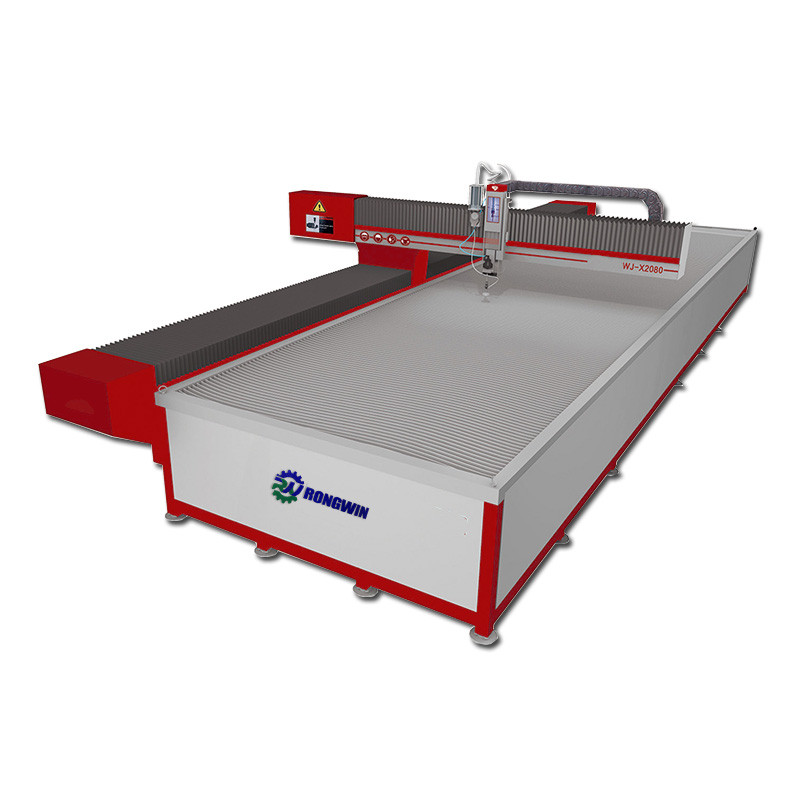

RONGWIN Customizable Waterjet Cutting Machine CNC Water Jet Cutter | Metal Plate And Pipe Cut

- Price

- US $50000-20000

- Model

- Waterjet Cutting Machine

- MOQ

- 1 piece

Item specifics

- country of origin

- China

- State

- New

- Video factory inspection

- Provided

- Mechanical test report

- Provided

- Marketing Type

- Hot Product 2024

- Core component warranty period

- 1 Year

- Core Components

- PLC/Engine/Bearing/Gearbox

- Warranty

- 3 Years

- Core selling point

- High-accuracy

Review

Description

Waterjet Cutting Machine Introduction

RONGWIN Waterjet Cutting Machine: Precision Cold-Cutting for a Wide Range of Materials

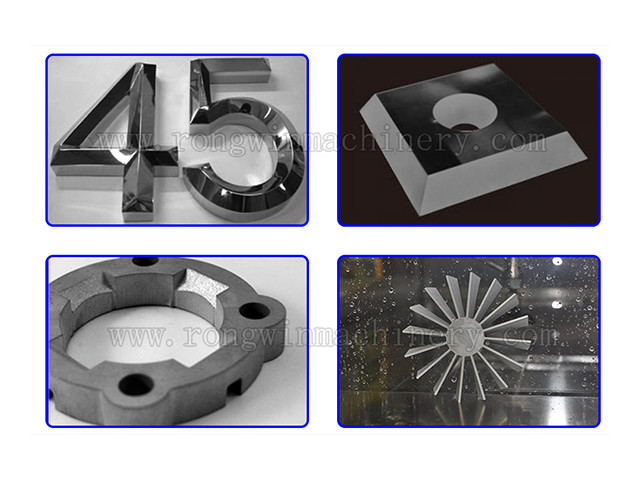

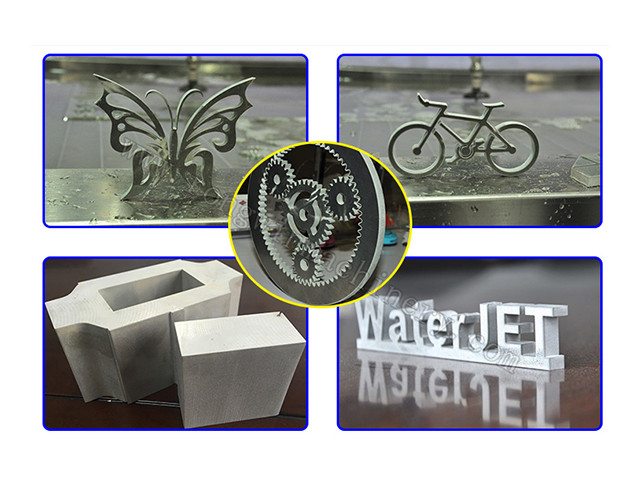

Rongwin Waterjet Cutting Machine Water Jet Cutter equipment operates with the world’s most unique cold-cutting technology, making it suitable for cutting any type of materials in a diverse range of industries. It is widely applied in the industry like steel, nonferrous metal, glass, stone and cemented carbide. In addition, our product is widely seen in the processing of plastic, man-made fiber cloth, paper, composite, food aviation and car interior decoration processing. Etc.

Featuring a low noise, no pollution, high precision and high reliability.

CNC water jet cutting machine consists of three basic parts: high pressure system, cutting platform and control system.

Waterjet Cutting Machine Application Scenario

Waterjet Cutting Machine Advantages

Feature 1

CNC Controller

1. High precision control

The CNC controller ensures high precision and stability during processing through precise algorithms and real-time processing, meeting the needs of complex shapes and precision components.

2. Automation and efficiency

The CNC controller supports automated operations, significantly reducing manual intervention and improving production efficiency. At the same time, mass production can be carried out to ensure processing consistency.

3. Programming flexibility

Supports multiple programming languages (such as G code), and can directly import designs through CAD/CAM software to simplify the process flow.

Feature 2

High Pressure Pump

Control: PLC

Shifting: electro-hydraulic

Control Cooling: cooler/oil heat exchanger

Inlet water filter accuracy: ≤0.45μm

Oil-return filter accuracy: 20 μm

Working temp: 0-50°c

Outlet: UNF 3/8" Cooling in/out-let: NPT1"

Max orifice size: 0.33mm

40HP/50HP/100HP

Waterjet Cutting Machine (Integral gantry type) Technical Parameters

CNC water-Jet Cuttng machine(Integral gantry type) offers a variety of models, covering a variety of needs from small to large, the specific technical parameters range as follows:

Parameters | Unit | RWWI-L1010 | RWJ-L1515 | RWWJ-L2015 | RWJ-L2515 | RWWI-L3015 | |

Efhcient Cutting area | mm | 1000*1000 | 1500*1500 | 2000*1500 | 2500*1500 | 3000*1500 | |

Axis travel | X | mm | 1000 | 1500 | 2000 | 2500 | 3000 |

Y | mm | 1000 | 1500 | 1500 | 1500 | 1500 | |

Z | mm | 150-180 | 150-180 | 150-180 | 150-180 | 150-180 | |

Cuting accuracy | mm | +/-0.1 | |||||

Positioning accuracy | mm | +/-0.02 | |||||

X,Y dry-run speed | m/min | 0-15 (ifneed 30mmin speed,we can do asrequest ) |

|||||

Cutting speed | m/min | as to detail material and thickness |

|||||

Parameters within this range reflect the wide applicability of the CNC water-Jet Cuttng machine(Integral gantry type) in different application scenarios, from small and medium-sized precision processing to large-scale industrial manufacturing.

Waterjet Cutting Machine (Split gantry type) Technical Parameters

CNC water-Jet Cutting machine(Split gantry type) offers a variety of models, covering a variety of needs from small to large, the specific technical parameters range as follows:

Parameters | Unit | RWVI-L3020 | RWWWJ-L4020 | RWWJ-L3040 | RWWWI-L2060 | |

Efhcient Cutting area | mm | 3000*2000 | 4000*2000 | 3000*4000 | 2000*6000 | |

Axis travel | X | mm | 3000 | 4000 | 3000 | 2000 |

Y | mm | 2000 | 2000 | 4000 | 6000 | |

Z | mm | 150-180 | 150-180 | 150-180 | 150-180 | |

Cuting accuracy | mm | +/-0.1 | ||||

Positioning accuracy | mm | +/-0.02 | ||||

X,Y dry-run speed | m/min | 0-15 (ifneed 30mmin speed,we can do as request ) |

||||

Cutting speed | m/min | as to detail material and thickness |

||||

Parameters within this range reflect the wide applicability of the CNC water-Jet Cutting machine(Split gantry type) in different application scenarios, from small and medium-sized precision processing to large-scale industrial manufacturing.

Waterjet Cutting Machine(Large Gantry type) Technical Parameters

CNC water-Jet Cutting machine(Large Gantry type) offers a variety of models, covering a variety of needs from small to large, the specific technical parameters range as follows:

Parameters | Unit | RWWJ-L3080 | RWWJ-L3570 | RWWJ-L20120 | RWWJ-L40120 | |

Efhcient Cutting area | mm | 3000*8000 | 3500*7000 | 2000*12000 | 4000*12000 | |

Axis travel | X | mm | 3000 | 3500 | 2000 | 4000 |

Y | mm | 8000 | 7000 | 12000 | 12000 | |

Z | mm | 150-180 | 150-180 | 150-180 | 150-180 | |

Cuting accuracy | mm | +/-0.1 | ||||

Positioning accuracy | mm | +/-0.02 | ||||

X,Y dry-run speed | m/min | 0-15 (ifneed 30mmin speed,we can do as request ) |

||||

Cutting speed | m/min | as to detail material and thickness |

||||

Parameters within this range reflect the wide applicability of theCNC water-Jet Cutting machine(Large Gantry type) in different application scenarios, from small and medium-sized precision processing to large-scale industrial manufacturing.

Waterjet Cutting Machine(Cantilever type) Technical Parameters

CNC water-Jet Cutting machine(Cantilever type) offers a variety of models, covering a variety of needs from small to large, the specific technical parameters range as follows:

Parameters | Unit | RWWJ-X1520 | RWWJ-X1530 | RWWI-X2030 | RWWJ-X2060 | RWWI-X2080 | |

Efhcient Cutting area | mm | 1500*2000 | 1500*3000 | 2000*3000 | 2000*6000 | 2000-8000 | |

Axis travel | X | mm | 1500 | 1500 | 2000 | 2000 | 2000 |

Y | mm | 2000 | 3000 | 3000 | 6000 | 8000 | |

Z | mm | 150-180 | 150-180 | 150-180 | 150-180 | 150-180 | |

Cuting accuracy | mm | +/-0.1 | |||||

Positioning accuracy | mm | +/-0.02 | |||||

X,Y dry-run speed | m/min | 0-15 (ifneed 30mmin speed,we can do as request ) |

|||||

Cutting speed | m/min | as to detail material and thickness |

|||||

Parameters within this range reflect the wide applicability of the CNC water-Jet Cutting machine(Cantilever type) in different application scenarios, from small and medium-sized precision processing to large-scale industrial manufacturing.

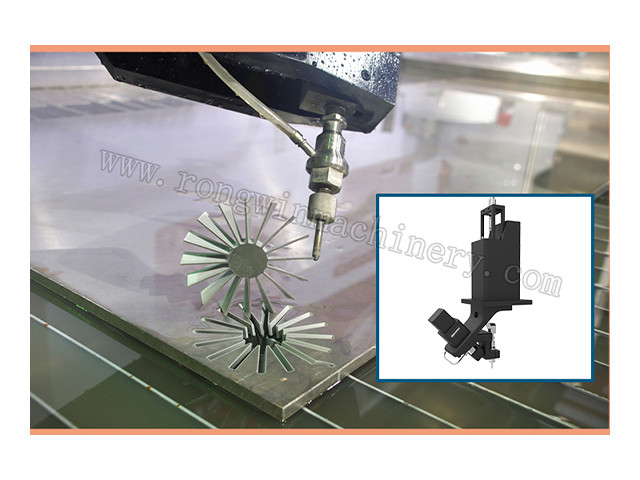

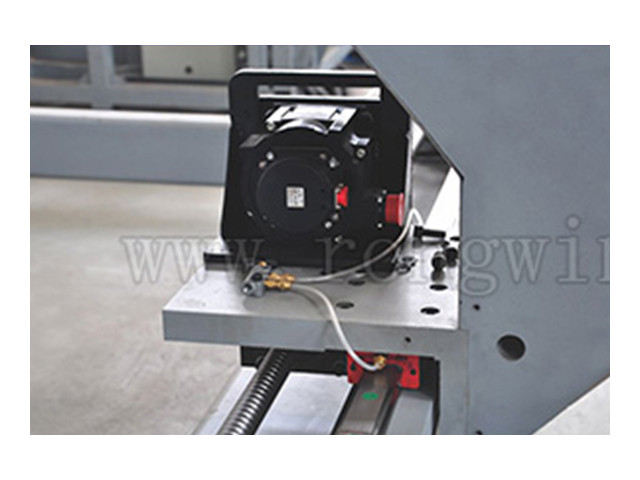

Waterjet Cutting Machine Details Display

Automatic lubrication device

Main motor

Drag chains

Bed

Waterjet Cutting Machine FAQ

What materials can a waterjet cutting machine cut?

Waterjet machines are versatile and can cut a wide range of materials, including metals (steel, aluminum, titanium), ceramics, glass, stone, composites, and plastics. They are particularly effective for heat-sensitive materials.

How does waterjet cutting work?

Waterjet cutting uses high-pressure water, often mixed with an abrasive substance, to erode material along a programmed cutting path. This process generates no heat, preserving material properties.

What are the advantages of using a waterjet cutter?

Precise, burr-free cutting

No heat-affected zones (HAZ)

Supports intricate designs and various thicknesses

Eco-friendly with minimal material waste

Compatible with various materials

What industries use waterjet cutting?

Industries such as aerospace, automotive, construction, manufacturing, and art/design use waterjet technology for its precision and adaptability.