Anhui Manufacturer's New Hydraulic Punching Machine | Long Service Life Punching Machine

- Price

- US $20000-3000

- Model

- 25-120T

- MOQ

- 1 piece

Item specifics

- Usage

- Metal hole punching

- Keyword

- power press machine

- Function

- Punching bending

- Power Source

- Hydraulic

- CNC or Not

- Normal

- Model

- 20Y-90T

- Certification

- CE ISO

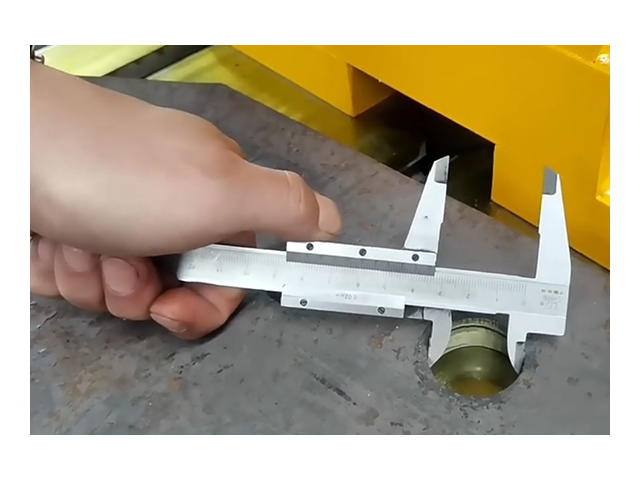

- MAX punching diameter

- 30mm

- Color

- Customized

Review

Description

Anhui Manufacturer's New Hydraulic Punching Machine Long Service Life Punching Machine

Anhui Manufacturer's New Hydraulic Punching Machine Long Service Life Punching Machine

Rongwin hydraulic punching machines used for punching all kinds of the whole hole, notch,slotof aluminium window profile,work with single mould and it is equipped with aluminum profilesingle mold and combination mold, capable of complete punch machining of all kinds of boresand slots of sliding window or casement window. The equilibrium of that machine is good, andthe accuracy is high. lt is easy to change the combination mold lt is the ideal equipment foraluminum window profile processing.Our hydraulic punching machines have been designed by experienced technicians, assisted bypowerful equipment and adapted to the ongoing suggestions many users.

Application Scenario

Advantages

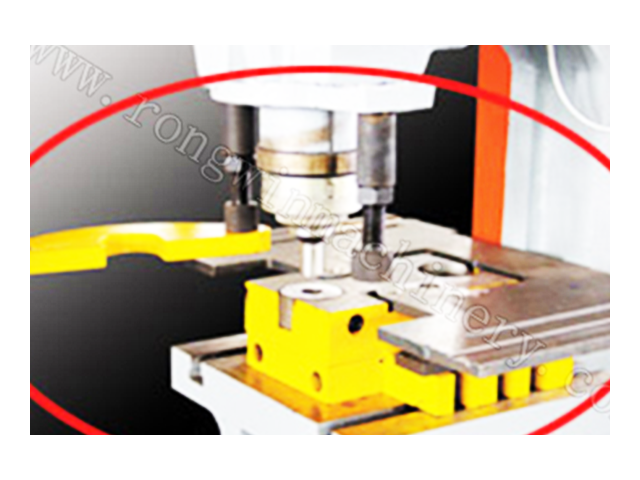

Feature 1

Punching

Quick punch change

Feature 2

Upper and lower mold

The rotating design is easy tooperate, and the nut and screwsleeve are easy to replace theupper and lower dies.

Hydraulic Punching Machine Technical Parameters

Hydraulic punching machine technical parameters series offers a variety of models, covering a variety of needs from small to large, the specific technical parameters range as follows:

Type | Punching pressure (T) | Material strength (mm) | Max. length of cylinder stroke(mm) | Trips frequency (times/min) | Punching thickness(mm) | Max. punching diameter (mm) | Power

(kw) | Dimension

LxWxH (mm) |

16Y-60T | 60 | ≤450 | 80 | 10-20 | 16 | 25 | 5.5 | 1400x700x1700 |

20Y-90T | 90 | ≤450 | 80 | 12-22 | 20 | 30 | 7.5 | 1600x800x1800 |

25Y-120T | 120 | ≤450 | 90 | 8-18 | 25 | 35 | 11 | 1800x960x2000 |

|

30Y-160T

|

160

|

≤450

|

100 | 6-16 |

30

|

38 | 15 | 2000x1050x2450 |

|

40Y-200T

|

200

|

≤450

|

110 | 6-16 |

40

|

40 | 18.5 | 2200x1050x2450 |

|

50Y-250T

|

250

|

≤450

|

200 | 6-16 |

50

|

45 | 18.5 | 2600x1440x2500 |

Parameters within this range reflect the wide applicability of the hydraulic punching machine technical parameters series shearing machine in different application scenarios, from small and medium-sized precision processing to large-scale industrial manufacturing.

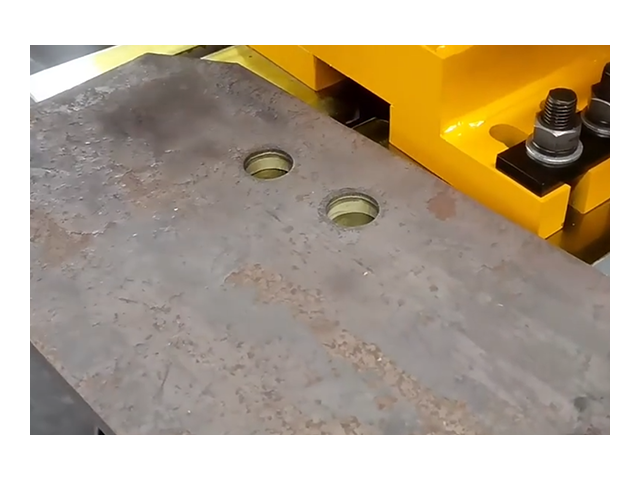

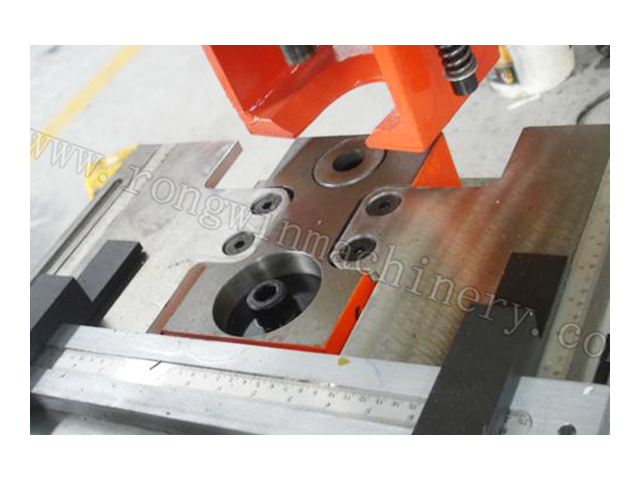

Hydraulic Punching Machine Details Display

Punching parts

Punching

Machine cabinet

Punching dies

Hydraulic Punching Machine FAQ

What is the cutting capacity of the Hydraulic Punching Machine shear?

The Hydraulic Punching Machine hydraulic guillotine shear has a cutting capacity of up to 16mm thickness and 4000mm width for various types of metal sheets.

What materials can the Hydraulic Punching Machine shear cut?

The machine is designed to cut a wide range of metals, including carbon steel, stainless steel, aluminum, and other non-ferrous materials.

How is the blade clearance adjusted on theHydraulic Punching Machine shear?

The blade clearance is adjustable, allowing for precise cutting based on the thickness of the material being processed. This ensures clean, accurate cuts with minimal burr.

What are the key features of theHydraulic Punching Machine shear?

Key features include an advanced hydraulic system, a user-friendly control interface, adjustable blade clearance, and a robust construction designed for long-term durability and stable performance.