Automatic CNC Robot Press Brake | Hydraulic Sheet Metal Bending for Steel Parts

- Price

- US $8800-7600

- Model

- CNC Robot Press Brake

- MOQ

- 1 piece

Item specifics

- Color

- yellow

- country of origin

- Anhui

- Applicable industries

- Manufacturing Plant

- weight

- 260

- marketing type

- Hot Product 2024

- core components

- PLC Engine Motor Gearbo Gear

- Core component shelf life

- 1 year

- brand

- RONGWIN

Review

Description

Automatic CNC Robot Press Brake Machine Hydraulic Sheet Metal Bending Cell System Carbon Steel Pump Bearing Gear Engine Steel

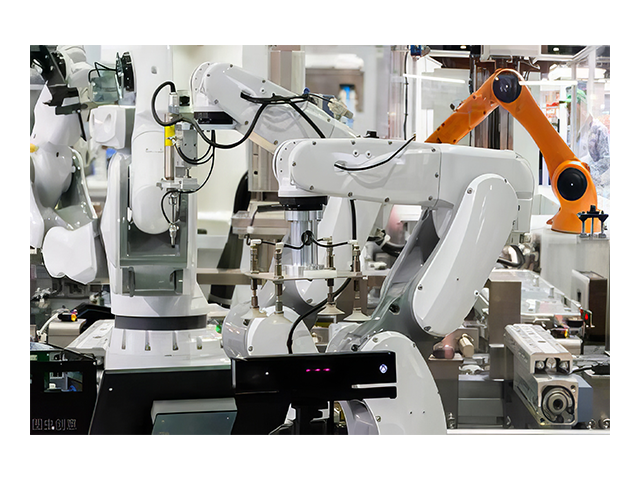

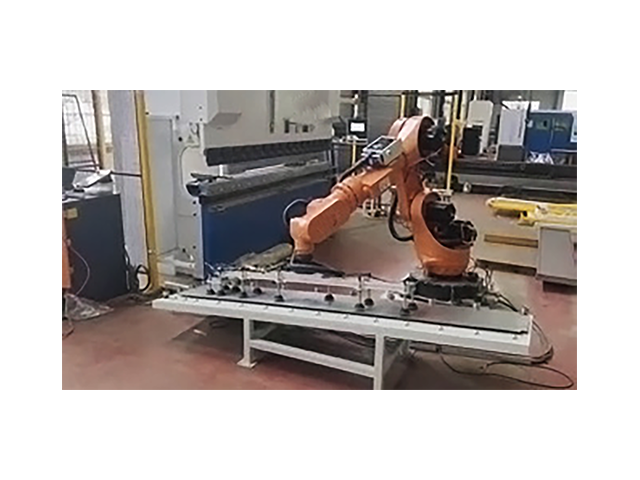

FULLY AUTOMATIC ROBOT

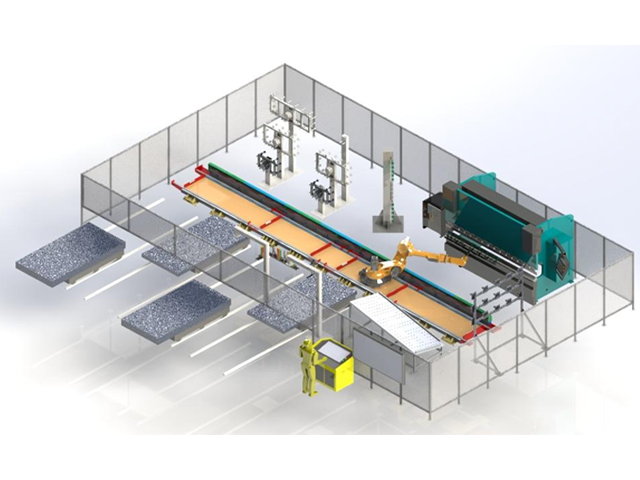

Production Flow

1.The robot grabs materials

from the loading area

2.The robot grabs the sheet and

places it on the centering table.

3.The robot grabs the sheet

(short side) and automatically aligns

the rear finger system

4.The robot grabs the sheet metal

bending machine and follows

the bending short edge

5.The robot grabs the sheet and

uses the turning frame to turn it over

6.The robot grabs the sheet

(long side) and automatically

aligns the rear finger system

7.The robot grabs the sheet metal

and the bending machine

follows the bending long edge

8.The robot puts materials into the

unloading area

Application Scenario

Advantages

1. Easier to use

Easy to install and teachEasy to maintain and use

2. High stability

The core components adopt imported configuration,with more stableperformanceand vibrationsuppression technology, which effectivelysuppressesthe low-frequencyvibration caused byacceleration and deceleration.

3. High efficiency

Trajectory planning technology based on dynamic model tooptimizerobot rhythm

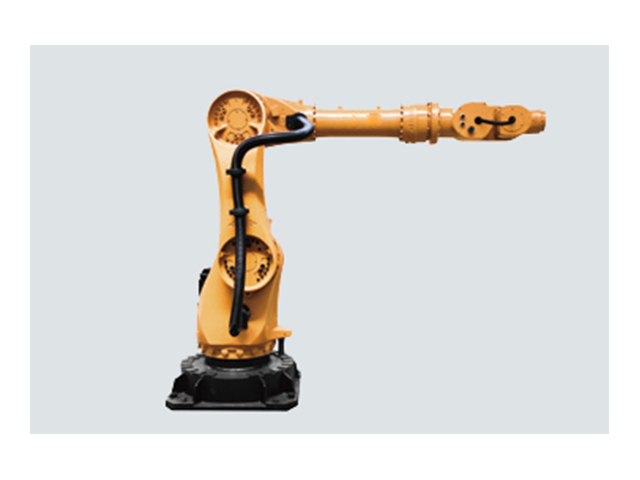

4. New structural design

Rod length ratio, small arm length ( X ) /big arm length ratio ( Y ) , meetsthe needs of the bending process Support higher palletizing height (H=1500mm)

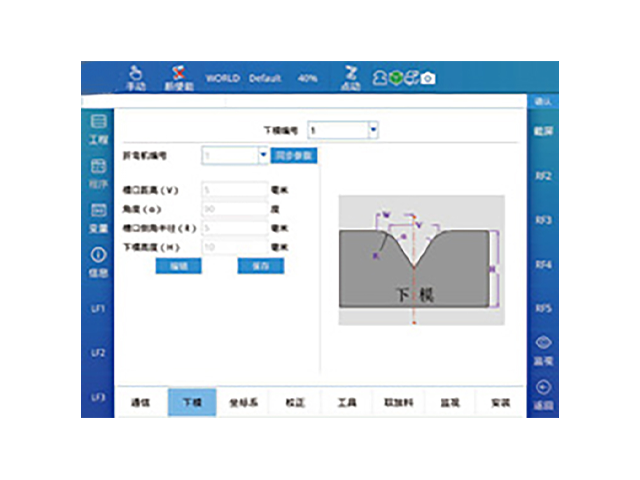

5. Humanized operating world

All configurations are integrated into one interface, making switching quickand convenient.Automatically generate a folded coordinate system in threestepsPlug and play with folded statements, no need for teaching,improving debugging efficiency

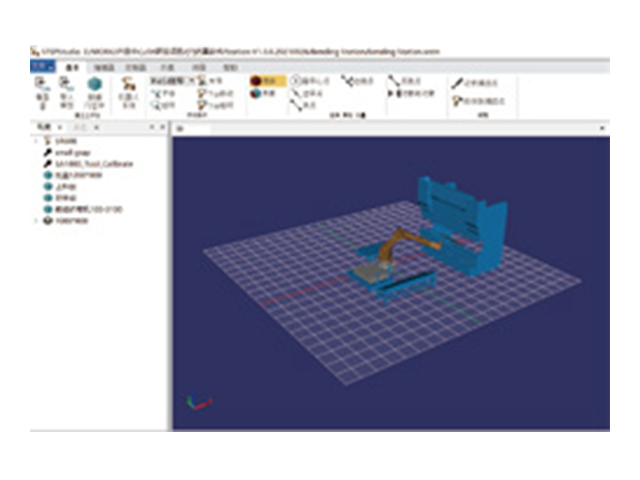

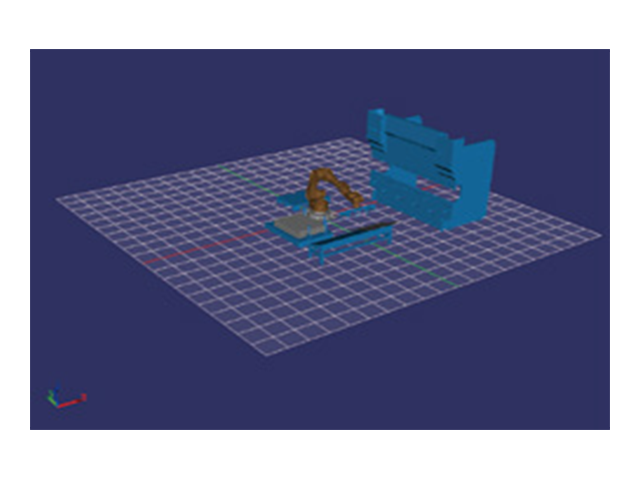

6. Bending simulation software

Comes with virtual controller and pC teaching pendant Supports teachingprogramming, motion simulation, reachability and beat testing

Technical specifications

|

Name

|

ER30

|

|

Action type

|

Multiple joints

|

|

Number of control axes

|

Number of control axes

|

|

Number of control axes

|

Floor decoration

|

Maximum joint speed J1axis | 145°/sec |

Maximum joint speed J2axis | 105°/sec |

Maximum joint speed J2axis | 170°/sec |

Maximum joint speed J4axis | 320°/sec |

Maximum joint speed J5axis | 320°/sec |

Maximum joint speed J6axis | 450°/sec |

Maximum activity radius | 1.6m |

Maximum allowable load on wrist | 30Kg |

Additional load allowed on third axis | 10Kg |

Repeat positioning accuracy | ±0.1mm |

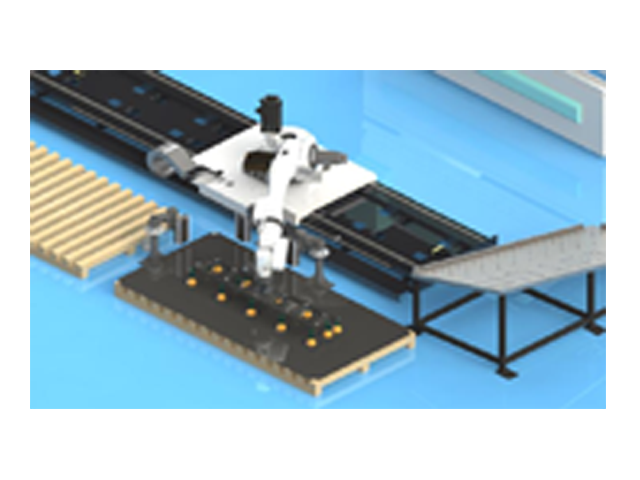

Detailed lmages

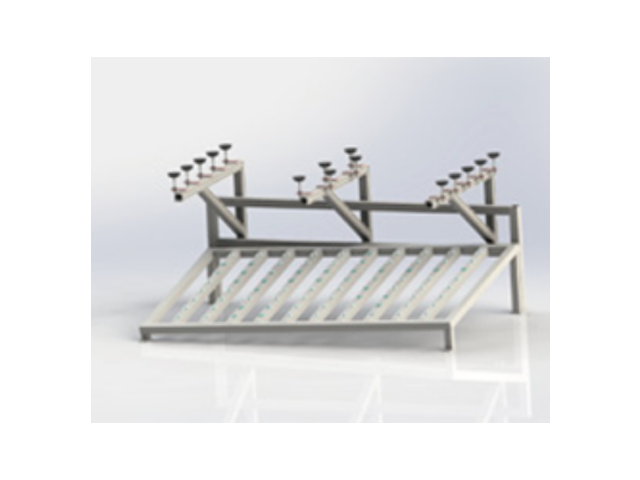

1. Robot gripper

Quick switching. Match different loads.Workpieces of different specificationsDiversification: suction cup method and magnet method

2. Robot track

Modular design, effective travel can becustomizedAutonomous servo drive, accuracy+0.1rrn.Self-lubricating system

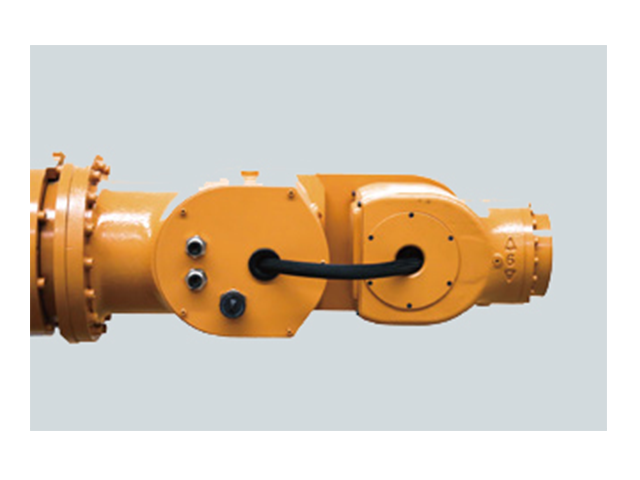

3. Face changing mechanism

Meet complex process requirements invarious forms: horizontal and vertical

4. The gravity centering mechanism has a modular design and various forms!

It can adapt to different sizes.Workpieces of different materials

5. Rear gear positioning mechanism

Standardized design. Easy andconvenient installationCheck the plate is in place

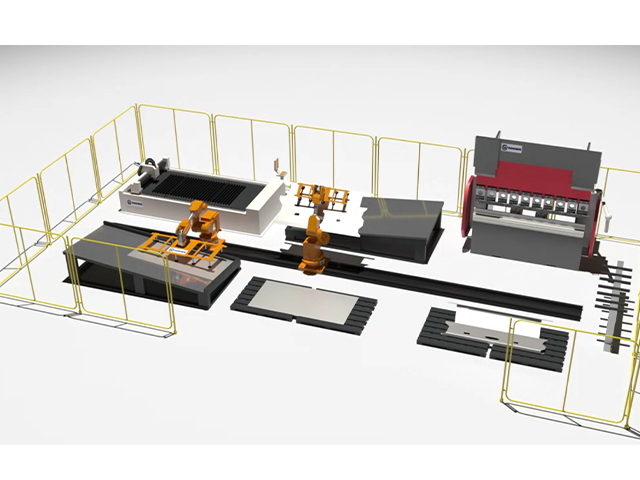

Specific application cases

In the sheet metal industry, the application of robotbending unitscan solve the production needs ofmultiple varieties, small batches, and fast switching.The LAG international robot press brake unit integratesa CNC bending machine, a KUKA 7-axis robot andguide rails, supporting loading stations, etc. Throughthe intelligent robot press brake unit, it can solve theproblems existing in the traditionalpress brake process,such as operation Problems such as inconsistentplacement of workpieces caused by the unsustainableendurance of workers, the need for multiple peopleto operate large workpieces, and poor work safety.

Workshop