Industry leaders visited! The delegation went deep into the RONGWIN factory to witness the high-precision bending technology innovation

- Share

- From

- Company

- publisher

- Daisy Li

- Issue Time

- Jun 20,2025

Summary

RONGWIN hosted key partners, touring R&D center & smart factory. Showcased CNC bending tech strength, paving way for strategic partnership.

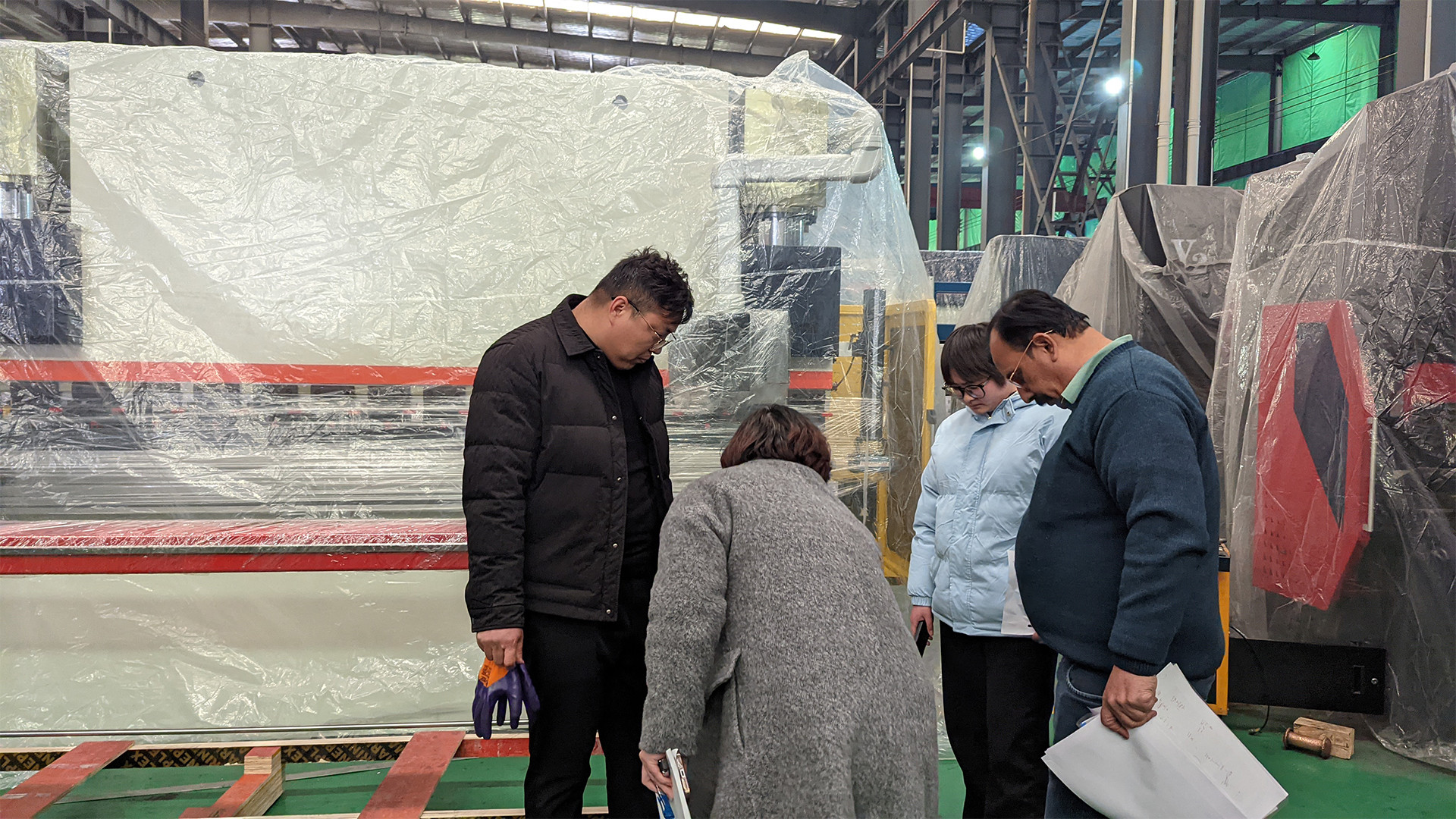

Industry leaders visited! The delegation went deep into the RONGWIN factory to witness the high-precision bending technology innovation

RONGWIN, a leading bending technology solution provider in China, welcomed an important partner, and the delegation came to provide guidance. The customer team went deep into RONGWIN's R&D center and intelligent production base to comprehensively inspect the core technology strength and manufacturing system of CNC bending machines, laying the foundation for strategic cooperation.

Highlights of the inspection were focused throughout the whole process

▶ Smart exhibition hall: immersive experience of the forefront of bending technology

Accompanied by the technical director of RONGWIN, the customers experienced the whole series of bending equipment at close range:

Dynamic demonstration of star models:

Electro-hydraulic synchronous CNC bending machine: ±0.1° ultra-high precision control technology, equipped with RONGWIN's self-developed "Sharp Intelligence" CNC system, to achieve one-click programming of complex workpieces;

Fully automatic bending unit: integrated robot loading and unloading + visual positioning system, on-site demonstration of unmanned and efficient production process;

Core technology decryption:

Rigid reinforced fuselage: imported high-quality steel plate welding + dual stress relief process to ensure the long-term stability of the equipment for ten years;

Intelligent compensation technology: real-time hydraulic deflection compensation + angle closed-loop feedback, to overcome the industry problem of thick plate rebound.

▶ Smart Manufacturing Workshop: Witness the Hard Power of Precision Manufacturing

The delegation went deep into the 10,000-level clean assembly workshop, and RONGWIN demonstrated its core technology with a "transparent factory":

German gantry pentahedron machining center: key component machining accuracy reaches 0.01mm;

Laser tracking weld detector: 100% full inspection of large structural parts welding quality;

72-hour continuous load test: each device has undergone rigorous factory tests that exceed the national standard by 30%.

▶ Strategic Talk: Co-drawing a blueprint for industry solutions

Both parties focused on the pain points of the [customer industry] field and conducted in-depth discussions:

RONGWIN proposed a customized solution for the "flexible bending production line" to solve customers' multi-variety small-batch production needs;

The technical team analyzed the "energy consumption cloud monitoring system" on site to help customers reduce 30% of the comprehensive energy efficiency cost.