Efficient direct access to customer sites

- Share

- From

- Company

- publisher

- Coke Fan

- Issue Time

- Feb 28,2025

Summary

Order verification: confirm order information and payment status to avoid wrong shipment and financial risks.

Inventory lock: the system reserves inventory and links production/purchase when out of stock.

Worry-free delivery of precision equipment: safe escort throughout the entire process, efficient direct delivery to customer sites

1. Overall packaging.

Multi-layer protection

First layer: Wrap anti-static film to prevent metal parts from oxidation.

Second layer: Wrap EPE pearl cotton (thickness ≥ 5cm), focusing on covering the corners.

Third layer: Cover with waterproof tarpaulin and tighten with binding tape.

Photo 1:Multi-layered protection.

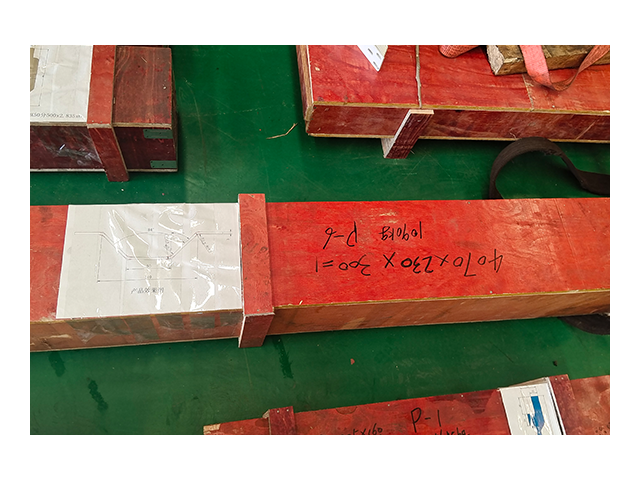

2. Split Packaging.

Disassemble by functional units (such as motor group, control cabinet, transmission mechanism).

Record the disassembly steps and take photos of the connection points for archiving.

Photo 2:Modular disassembly.

Transport risk assessment

3. Transport risk assessment.

Plan split or whole transport plans based on equipment size (e.g. 3m long x 1.5m wide x 2m high) and weight (e.g. 2.5 tons).

Confirm height and weight limits on transport routes to avoid delays due to road restrictions.

Photo 3:Transport risk assessment

4. Equipment Pre-check.

Functional test: no-load running test bending accuracy, hydraulic system pressure value, CNC system response.

Appearance inspection: integrity of the machine body anti-rust coating, clarity of the label (power/voltage), completeness of accessories (foot switch, manual).

Quality inspection report: attached with a third-party inspection report (such as accuracy ±0.1mm certification).

Photo 4: Equipment Pre-check.