Fiber Laser Cutting Thickness: How Thick Can Fiber Laser Cut Different Metals

- Share

- Issue Time

- Oct 9,2025

Summary

Discover how fiber laser cutting machines handle various metals, from thin sheets to thick plates. Cutting performance depends on laser power, material type, and speed. Fiber lasers also support engraving applications, offering precise, clean results. Choosing the right laser cutter for metal ensures efficiency, quality, and reduced production costs in industrial and custom fabrication projects.

Understanding the maximum thickness a fiber laser cutting machine can handle is crucial for metal fabrication, industrial projects, and precision applications. Using guesswork can lead to inefficiencies, poor-quality cuts, and increased production costs. This guide will explain how thick a fiber laser cutter can cut various metals, factors that influence cutting performance, and tips for optimizing results.

What is a Fiber Laser Cutting Machine?

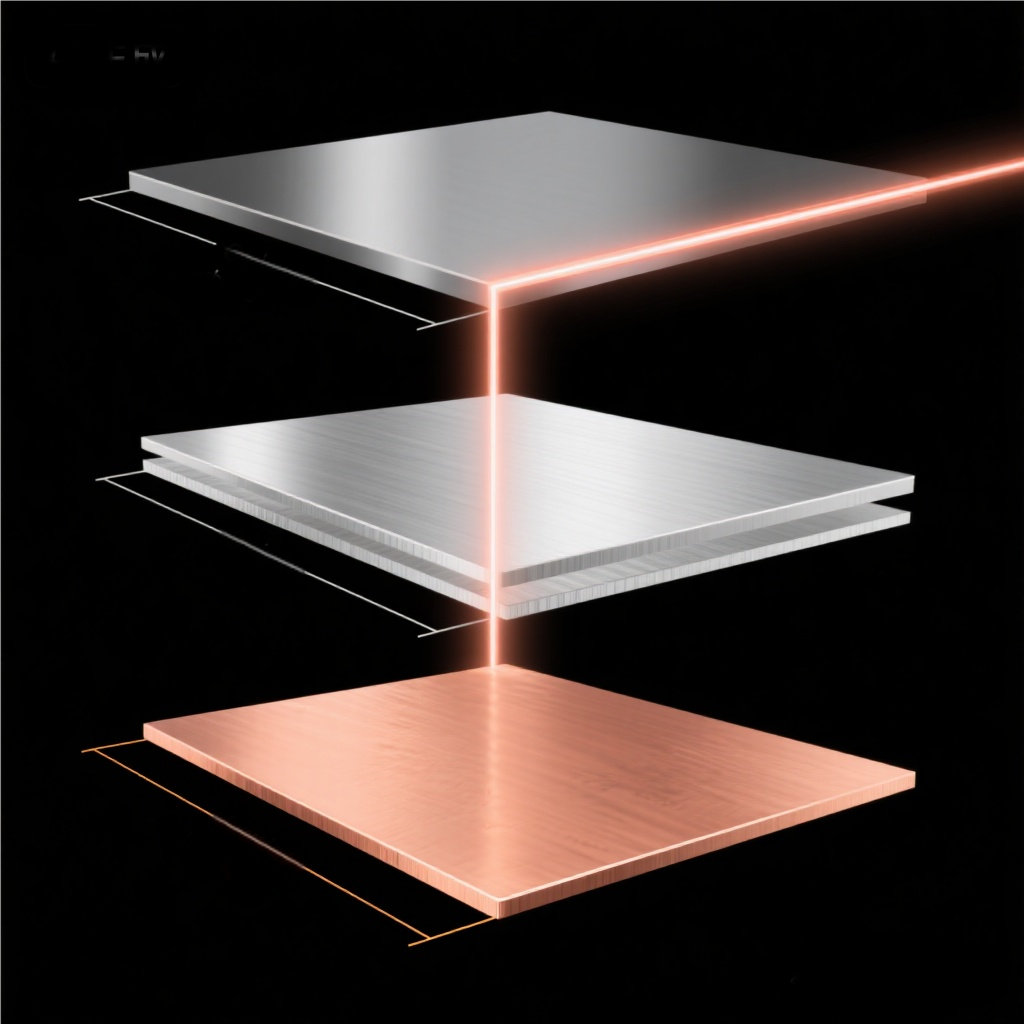

A fiber laser cutting machine uses a high-intensity, focused laser beam to cut through materials with precision. Fiber lasers are known for their ability to produce clean edges, minimal kerf, and high-speed operation. They are widely used in industries such as automotive, aerospace, construction, and electronics.

The key advantage of a fiber laser cutter is its versatility. It can handle both thin and thick metals while also supporting engraving applications. Fiber lasers operate with a wavelength of approximately 1.06 microns, which allows for efficient energy absorption in metals like stainless steel, carbon steel, aluminum, copper, and brass.

How Thick Can a Fiber Laser Cut Different Metals?

The cutting thickness depends mainly on laser power, material type, and cutting speed. Below is a table summarizing common metals and recommended thickness ranges for fiber laser machines, showing both millimeters and inches for convenience.

| Laser Power (W) | Material | Maximum Cutting Thickness (mm) | Maximum Cutting Thickness (in) |

| 500 | Carbon Steel | 6 | 0.24 |

| 500 | Stainless Steel | 3 | 0.12 |

| 500 | Aluminum | 2 | 0.08 |

500 | Copper | 2 | 0.08 |

1000 | Carbon Steel | 10 | 0.39 |

1000 | Stainless Steel | 5 | 0.20 |

1000 | Aluminum | 3 | 0.12 |

1000 | Copper | 3 | 0.12 |

2000 | Carbon Steel | 20 | 0.79 |

2000 | Stainless Steel | 8 | 0.31 |

2000 | Aluminum | 6 | 0.24 |

2000 | Copper | 4 | 0.16 |

4000 | Carbon Steel | 30 | 1.18 |

4000 | Stainless Steel | 12 | 0.47 |

4000 | Aluminum | 10 | 0.39 |

4000 | Copper | 6 | 0.24 |

⚡ Note: High-power fiber lasers (4000W and above) can handle thicker plates efficiently, while lower-power machines are ideal for thin sheets and precision cuts.

Key Factors Affecting Cutting Thickness

Several factors influence how thick a fiber laser can cut:

Laser Power

Laser power is the most significant factor. Higher wattage machines can cut thicker materials. For example, a 500W fiber laser cutter is suitable for thin sheets, while a 4000W fiber laser cutting machine can handle plates up to 30 mm thick.

Material Properties

Thermal Conductivity: Materials like copper dissipate heat quickly, requiring higher laser power.

Reflectivity: Aluminum and brass reflect more laser energy, needing careful focus and optimized settings.

Strength and Density: Harder metals like stainless steel require more energy to cut cleanly.

Cutting Speed

Faster cutting speeds improve productivity but may reduce maximum thickness capacity. Optimizing speed ensures a clean edge without overburn or melting.

Focus and Lens Quality

Precise focus concentrates the laser beam on the material. High-quality lenses maintain beam sharpness, increasing cutting efficiency, especially for thicker metals.

Nozzle and Assist Gas

The nozzle diameter and gas flow help remove molten material. Proper adjustments support thicker cuts and reduce burrs.

Fiber Laser for Engraving vs. Cutting

While fiber lasers excel in cutting metals, they are also widely used for engraving. The key differences include:

| Application | Focus | Laser Power | Material Thickness |

| Cutting | Deep penetration | Medium to high | Thin to thick metal sheets |

| Engraving | Surface marking | Low to medium | Thin metals, plastics, composites |

Fiber laser engraving allows detailed designs on metals and non-metals, while cutting focuses on separating materials. Machines labeled as fiber laser for engraving or laser for engraving machine are optimized for high-precision surface work rather than through-cutting thick plates.

Tips for Choosing the Right Laser Cutter for Metal

1. Identify Your Material Range: Determine if you'll mainly cut stainless steel, carbon steel, aluminum, or copper.

2. Check Required Thickness: Match your material thickness with the fiber laser cutter’s power.

3. Consider Multi-Functionality: Some machines support both cutting and engraving for added versatility.

4. Review Maintenance and Reliability: High-quality optics and cooling systems improve performance.

5. Optimize Workspace Layout: Ensure your production area can safely accommodate the machine size and assist gas requirements.

Using a powered laser with sufficient wattage and optimized settings ensures consistent performance and reduced production costs.

FAQ

Q1: What is the thinnest material a fiber laser can cut?

A1: Fiber lasers can cut metal sheets as thin as 0.5 mm (0.02 in), producing precise edges with minimal kerf.

Q2: Can I use a fiber laser for both cutting and engraving?

A2: Yes. Many machines support both functions, but cutting thicker metals requires higher power, while engraving uses lower power for surface marking.

Q3: Does cutting speed affect maximum thickness?

A3: Yes. Higher speeds may limit the thickness that can be cleanly cut. Balancing speed with laser power ensures optimal results.

Q4: Why is laser power important?

A4: Higher power allows the laser to melt or vaporize thicker materials efficiently, increasing the maximum cutting thickness.

Q5: Are fiber lasers suitable for aluminum and copper?

A5: Yes, but reflective metals require precise focus, optimal lens quality, and sometimes higher power for clean cuts.