Beyond a single process: bending, slotting, and laser work together to create a complete solution for precision metal workpieces

- Share

- publisher

- Daisy Li

- Issue Time

- Jun 23,2025

Summary

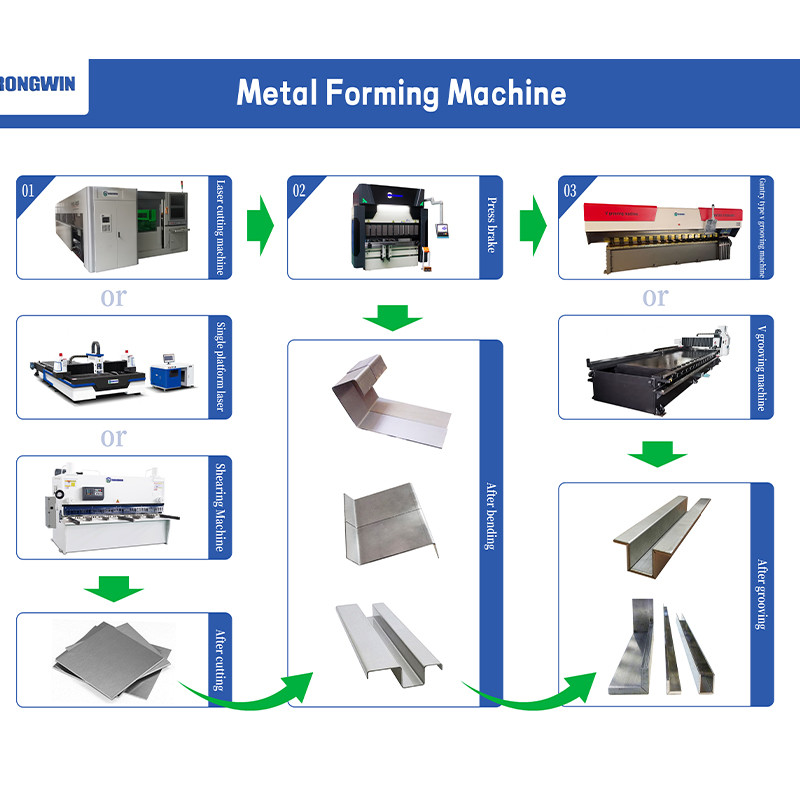

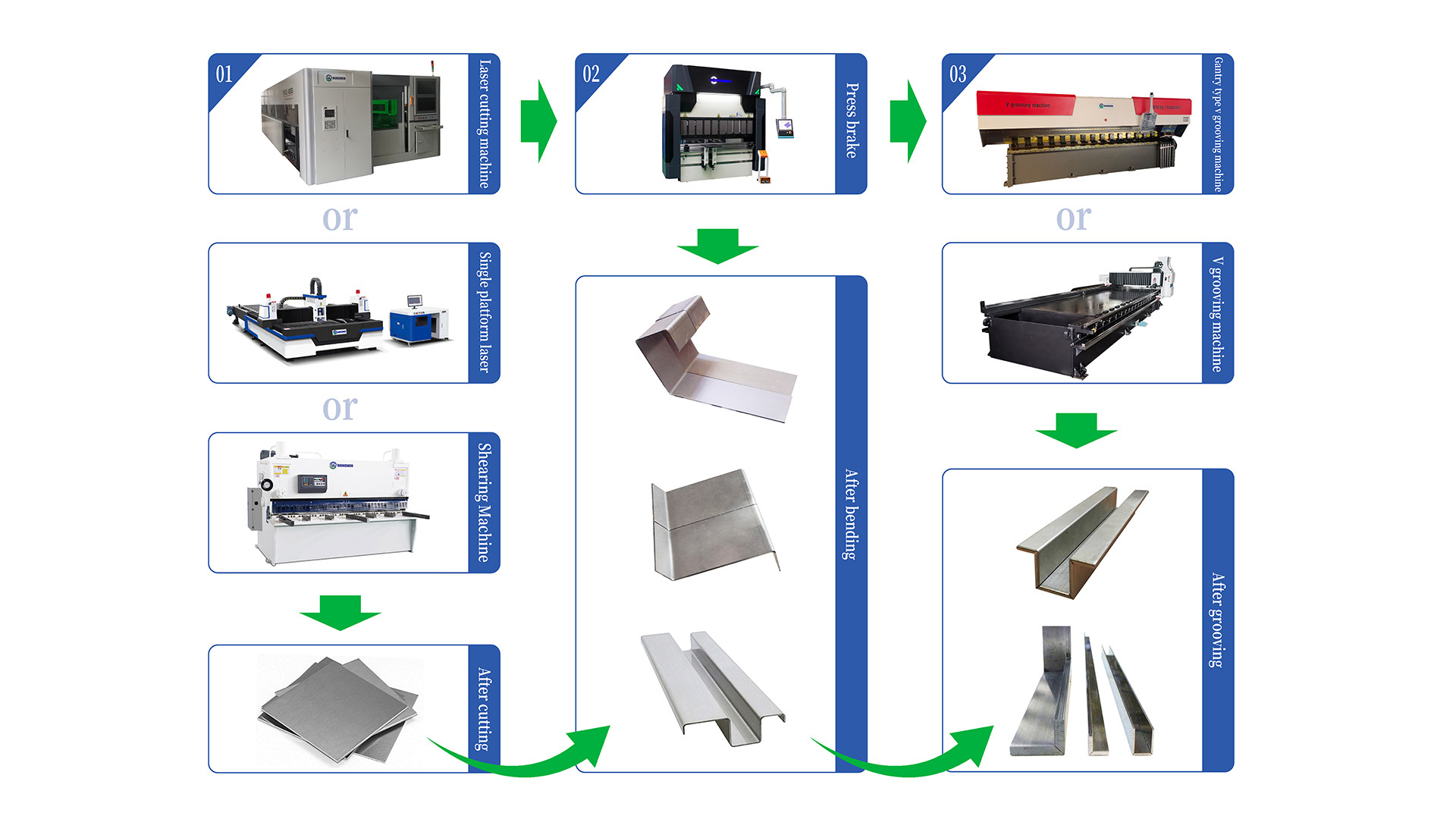

Precision manufacturing demands more than single machines. For complex metal parts, success requires seamlessly integrated processes. We combine [grooving machine], [bending machine], and [laser cutting machine] into one solution—delivering excellence from design to finished product.

Beyond a single process: bending, slotting, and laser work together to create a complete solution for precision metal workpieces

Unlocking a new realm of metal processing with complex structures, high precision and high efficiency

In the modern manufacturing industry that pursues extreme efficiency and precision, the capabilities of a single device are often unable to meet all the needs of complex workpieces. Faced with delicate structures and demanding metal parts, the key to success is to seamlessly connect multiple advanced processing technologies to form a complete solution. Today, we will explore in depth how to integrate the power of the three core devices of [grooving machine], [bending machine] and [laser cutting machine] to create an excellent metal processing solution for you from design to finished product.

Core of the solution: precise coordination of three major processes

Laser cutting machine - the basis for precise shaping:

Role: The first step of the solution, responsible for accurately cutting metal sheets (stainless steel, carbon steel, aluminum plates, etc.) into the required flat contours.

Advantages: No contact processing, no tool wear, can easily achieve complex shapes, fine holes (such as mounting holes, heat dissipation holes), and engraving marks. High precision (±0.1mm or even higher) lays a solid foundation for subsequent processes. Fast speed and high material utilization.

Value in this solution: Provide accurate blanks to ensure that the slit position and bending line benchmarks are accurate.

Grooving Machine - The key to complex bending and assembly:

Role: Accurately process V-shaped, U-shaped or other specific grooves at the bending line or in areas that require special forming.

Advantages: Remove some material, significantly reduce the force required for bending, reduce the bending radius, and avoid cracks or deformation on the sheet surface caused by extrusion (especially on thick plates or hard materials). It is the core process for achieving "zero radius" bending, hinge structures, special curling or assembly buckles.

Value in this solution: Create ideal conditions for subsequent high-precision bending, which is an indispensable link in achieving complex geometric shapes (such as boxes, parts with flanges or inward buckles), and improve the strength and aesthetics of the workpiece.

Bending machine - giving workpieces three-dimensional life:

Role: The final forming step of the solution, using precision molds to bend the slotted flat sheet into a preset three-dimensional angle and shape.

Advantages: Thanks to the slotting process, the bending process is smoother and more precise, with less springback and extremely high angle consistency. Multiple bends can be completed to form various three-dimensional structures such as boxes, brackets, and shells.

Value in this solution: Efficiently and high-quality conversion of precisely cut and slotted flat parts into the final required three-dimensional workpiece.

Synergistic advantages: 1+1+1 > 3

Higher precision and more complex design: Fine laser cutting + slotting for precise preparation of bending lines + precision forming of bending make it possible to process workpieces with extremely small tolerances, sharp corners, and complex internal structures.

Better surface quality and strength: Slotting effectively avoids surface indentations or cracks that may be caused by traditional bending, and improves the strength of the workpiece (especially when the slot design is reasonable) and appearance quality.

Higher efficiency and lower cost: Reducing or eliminating secondary processing (such as drilling and tapping can be partially integrated in laser cutting), optimizing the process flow, and shortening the manufacturing cycle. Precise blanking and efficient forming reduce material waste and labor costs.

Wider material adaptability: This solution is particularly good at processing difficult-to-bend materials such as thick plates, high-strength steel, and aluminum alloys. Slotting reduces the difficulty of bending and ensures forming quality.

Improved design freedom: Engineers are no longer limited to the processing capabilities of a single device when designing, and can more freely conceive metal parts with more complex structures and more integrated functions.

Typical application workpieces:

Precision chassis/cabinets: Laser cutting of the shape and heat dissipation holes -> Slotting of the bending line -> Precise bending to ensure a perfect fit.

Heavy equipment brackets/frames: Laser cutting -> Slotting of key stress-bearing parts -> High-precision bending to ensure strength and assembly accuracy.

Panels with special flanging/curling: Laser cutting -> Slotting of specific positions -> Bending to form inward buckling, outward turning or curling structures.

Ventilation ducts/sheet metal shells: Laser cutting of complex flange contours -> Slotting of connection edges -> Bending into tubular or special-shaped shells.

Medical equipment/laboratory equipment components: Meet the requirements of high cleanliness, high precision and complex structures.

Why choose our collaborative solution?

At RONGWIN, we not only have advanced [grooving machine model/brand], [bending machine model/brand] and [laser cutting machine model/brand] equipment, but more importantly, we know how to make these equipment work together. Our team of engineers is proficient in the characteristics and processing technology of various metal materials. According to your workpiece drawings, we can optimize the process route (cutting->grooving->bending sequence planning), accurately calculate the matching of groove depth, position and bending parameters, ensure the whole process is smooth and efficient, and finally deliver you a precision metal workpiece that meets or exceeds your expectations.

Contact Us:

No matter how complex your workpiece design is or how challenging the material is, RONGWIN's one-stop bending-grooving-laser collaborative processing solution can provide you with efficient, accurate and reliable manufacturing guarantees. Contact our technical experts now to discuss your project needs!