Advantages of Hybrid CNC Press Brakes Compared to Traditional Models

- Share

- publisher

- Daisy Li

- Issue Time

- Jul 29,2025

Summary

The Hybrid system uses a servo-driven hydraulic pump that consumes energy only when in operation, thus achieving a "zero power consumption" state when not in operation, improving efficiency and response speed

Precision, Repeatability and Speed: Why Hybrid CNC Press Brakes Are the Future of Sheet Metal Fabrication

In the world of metalworking, speed is essential... At Rongwin Machinery, we embrace innovation with our high‑performance WF67K‑M Series hybrid press brakes.

What Is a Hybrid CNC Press Brake?

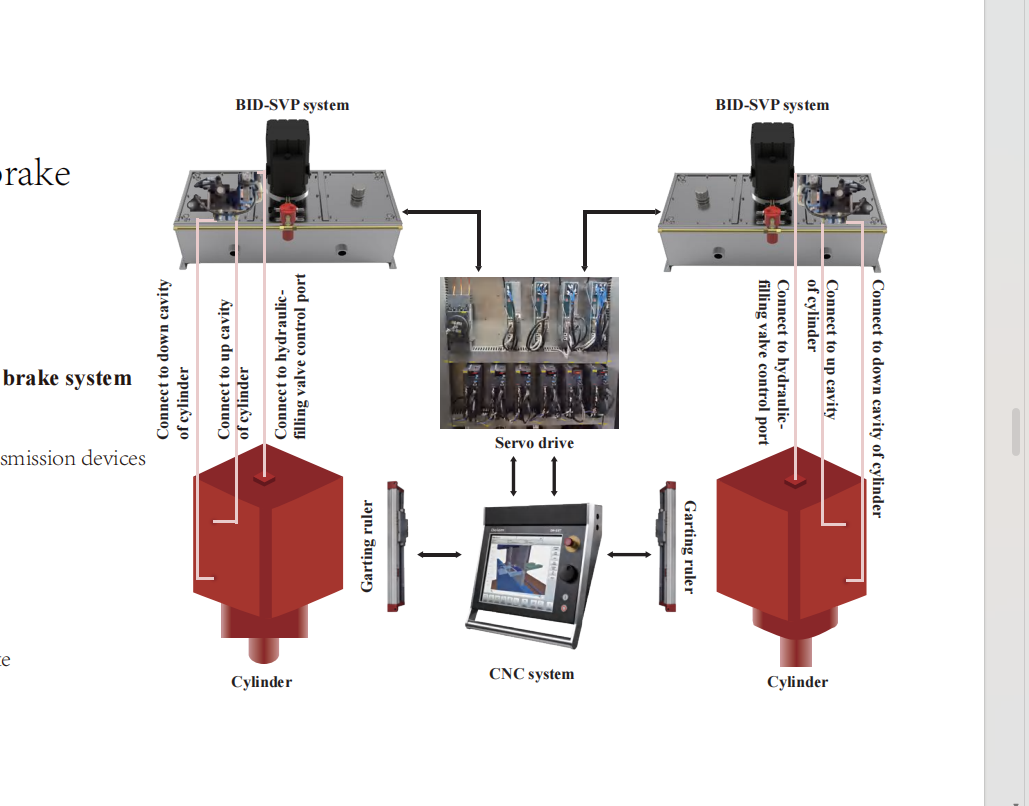

A hybrid CNC press brake combines hydraulic force with servo precision... servo‑driven hydraulic pumps activate only when needed—delivering outstanding energy efficiency and motion control.

Why Precision Matters in Metal Fabrication

±0.1 mm Can Make or Break the Final Product

Whether you're manufacturing elevator panels, aerospace parts, or stainless steel cabinets... Hybrid CNC press brakes like Rongwin’s offer:

- Positional accuracy of up to ±0.1 mm

- Angle accuracy within ±0.5°

- Automatic compensation for thickness and springback

These capabilities ensure large batches remain interchangeable and precise.

Repeatability: Consistency You Can Count On

Less Variance, Less Waste

Hybrid CNC reduces scrap and rework via:

- Closed-loop feedback with linear encoders

- Servo-driven backgauges with ball screws

- Programmable bending sequences for consistent repeat performance

Speed and Efficiency: Faster Without Sacrificing Accuracy

Servo‑Hydraulics = More Bends per Hour

Hybrid press brakes reduce energy use by up to 75%, deliver faster ram travel, and minimize heat buildup. Rongwin’s dual‑servo pumps only activate during bending, boosting throughput.

Application Industries: From Auto to Architecture

Versatility Across Sectors

Ideal for automotive frames, aerospace alloy parts, elevator panels, telecom enclosures. With tonnage ranges from 40T–600T and various bending lengths, we support both high‑mix and high‑volume production needs.

Why Rongwin?

Engineered for Precision, Built for Reliability

Rongwin Machinery offers:

- 15+ years of precision sheet metal machine experience

- CE‑certified machines and customizable OEM/ODM configurations

- Global service network and technical support

Conclusion

Hybrid CNC press brakes combine hydraulic strength and servo finesse. They deliver faster output, lower waste, and consistent quality. With Rongwin, your investment gives long‑term competitive advantage.