Achieving a Flawless Finish: The Power of Polishing Machines in Metal and Surface Treatment

- Share

- publisher

- Daisy Li

- Issue Time

- Dec 18,2024

Summary

Polishing machines are essential for achieving smooth, high-quality finishes on metal surfaces. They eliminate imperfections, enhance shine, and improve the aesthetic of metal parts. This blog explores the role of polishing machines in industries like automotive, aerospace, and manufacturing, highlighting their impact on product quality, durability, and efficiency. Learn how choosing the right polishing machine can elevate your production and deliver flawless results.

Maximizing Efficiency in Fabrication with Automation: The Role of Polishing Machines

Labor shortages continue to challenge industries worldwide, and stone fabricators are among those feeling the pinch. With fewer hands available, many fabrication shops are focusing on increasing production efficiency and reducing bottlenecks in processes like backsplash and countertop production. Polishing machines, particularly flat-edge polishers like the RONGWIN, are revolutionizing these workflows, ensuring higher productivity and cost-effectiveness.

1. Addressing Common Bottlenecks

Two prevalent issues in countertop fabrication are:

1. Labor-intensive Manual Polishing: Manual backsplash polishing is time-consuming, adding significant labor hours to projects.

2. Overloaded CNC Routers: Many shops struggle with CNC routers becoming production bottlenecks, delaying other tasks.

2. Benefits of Automation in Polishing

Investing in automated polishing machines provides solutions to these challenges:

Increased Efficiency: A flat-edge polisher can process up to 325 lineal feet per hour compared to the 20–25 feet achieved by manual polishing. This efficiency translates to roughly 16 times the productivity of hand polishing.

Cost-Effectiveness: Replacing manual labor with automated machines reduces labor costs while maintaining consistent quality.

Improved Workflow: Machines like the RONGWIN simplify operations with a load-and-go design, requiring no programming for linear tops. This allows CNC routers to focus on other tasks.

Enhanced Predictability: Unlike human labor, machines deliver consistent output without variability due to fatigue or absences, making scheduling easier.

3.Real-World Impact

Fabricators have experienced significant benefits after adopting automated polishing solutions. Joe Duszka of Carolina Custom Surfaces noted that running the FASTBACK® II for 1–2 hours replaced an entire day’s work for two polishers. Similarly, Roger Atherton of Counter Effects highlighted saving 14 labor hours daily, resulting in a rapid return on investment.

4. Broader Impacts of Polishing Machines

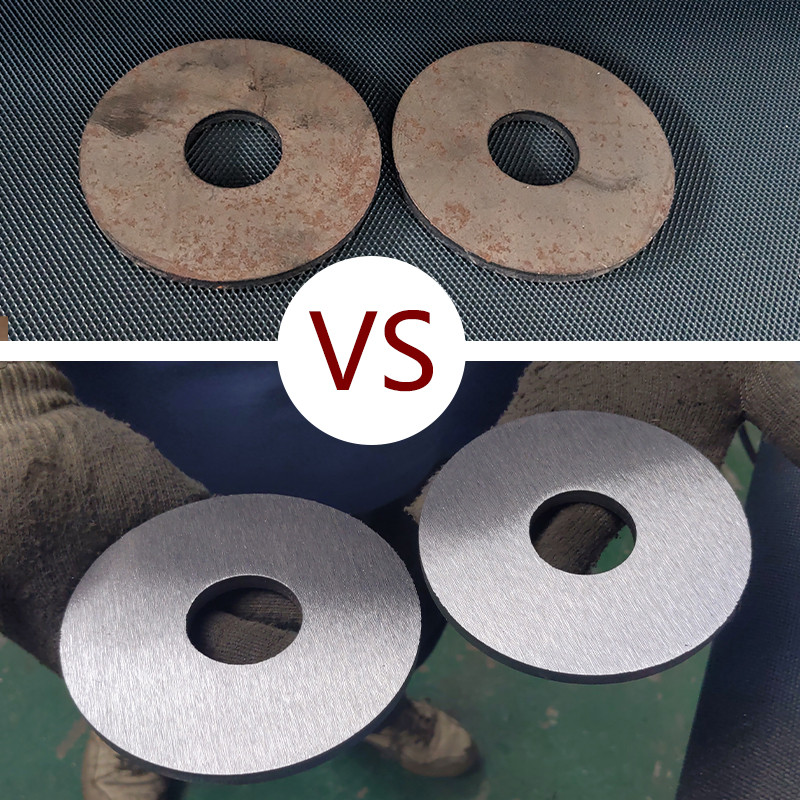

Polishing machines are also transforming the metalworking industry. By automating the polishing process, manufacturers achieve:

Precision and Consistency: Uniform finishes with minimal effort.

Reduced Labor Costs: Freeing skilled workers for complex tasks.

Safety and Sustainability: Minimized injury risks and reduced environmental impact with dust collection systems.

5. Future Prospects

Technological advancements like robotic polishing and AI-driven systems are set to further enhance efficiency and precision, ensuring polishing machines remain integral to fabrication and manufacturing.

6. Versatility: Polishing machines can be used on a variety of materials, including metals (stainless steel, aluminum, etc.), plastics, wood, and even ceramics, making them versatile tools for different industries.

Applications of Polishing Machines

1. Metal Finishing: Polishing is crucial in industries like automotive and aerospace, where parts need to be free of imperfections and have a smooth, shiny surface.

2. Jewelry: Polishing machines are widely used in the jewelry industry to achieve the lustrous finish that high-quality jewelry demands.

3. Woodworking: Wood polishing machines help achieve a smooth finish on wooden surfaces, adding shine and enhancing the material’s natural beauty.

4. Manufacturing: Polishing machines help in the final stages of production, improving the aesthetic appeal and surface quality of products.

Conclusion

Whether you’re dealing with stone countertops or intricate metalwork, polishing machines streamline operations, reduce costs, and enhance output quality. For fabricators, adopting this automation not only alleviates labor shortages but also positions them for sustainable growth in a competitive market.